Fabrication of compact opto-electronic component packages

A technology of packages and components, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as inflexible design changes, difficulties in specific application design, and large mechanical tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

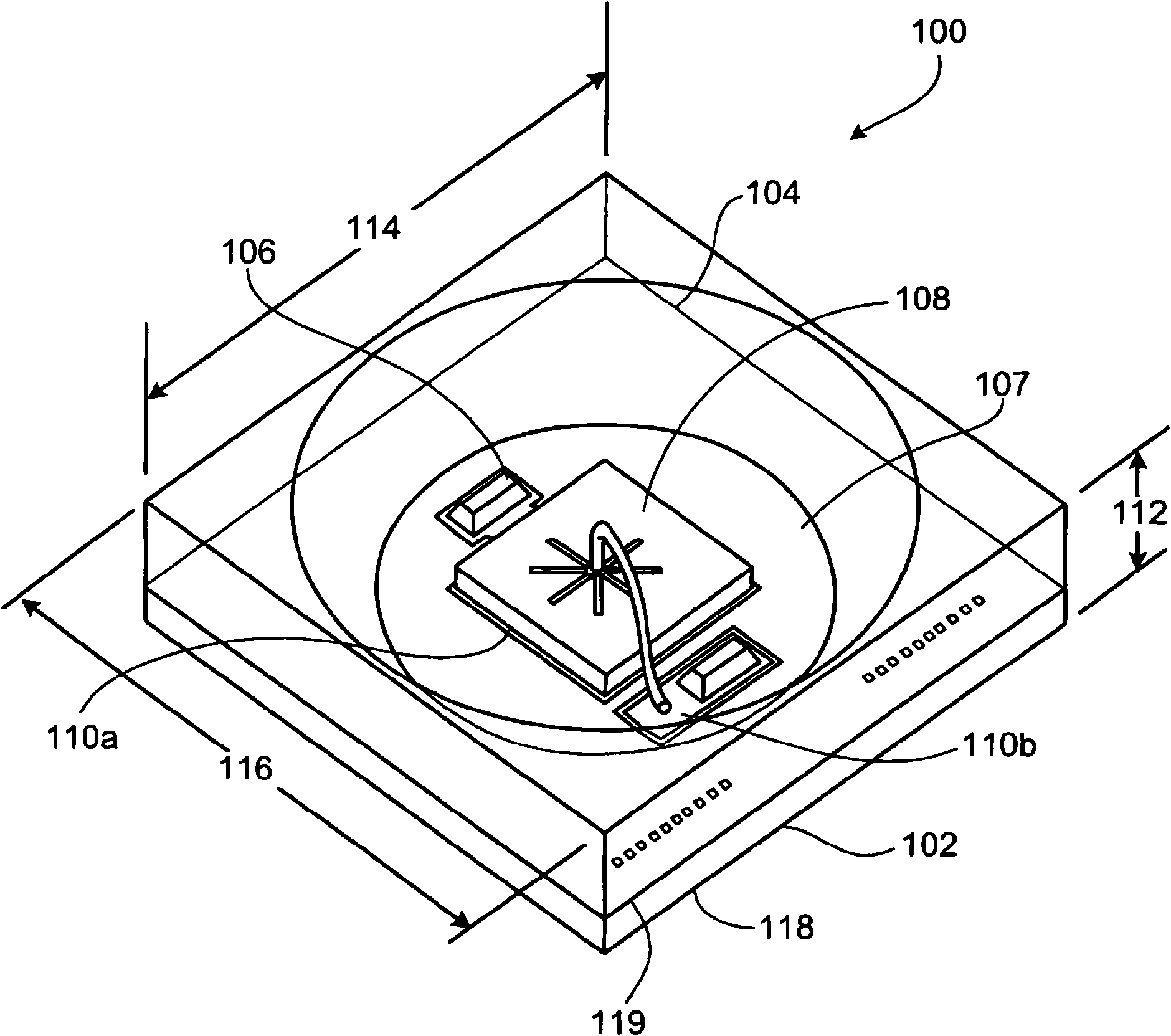

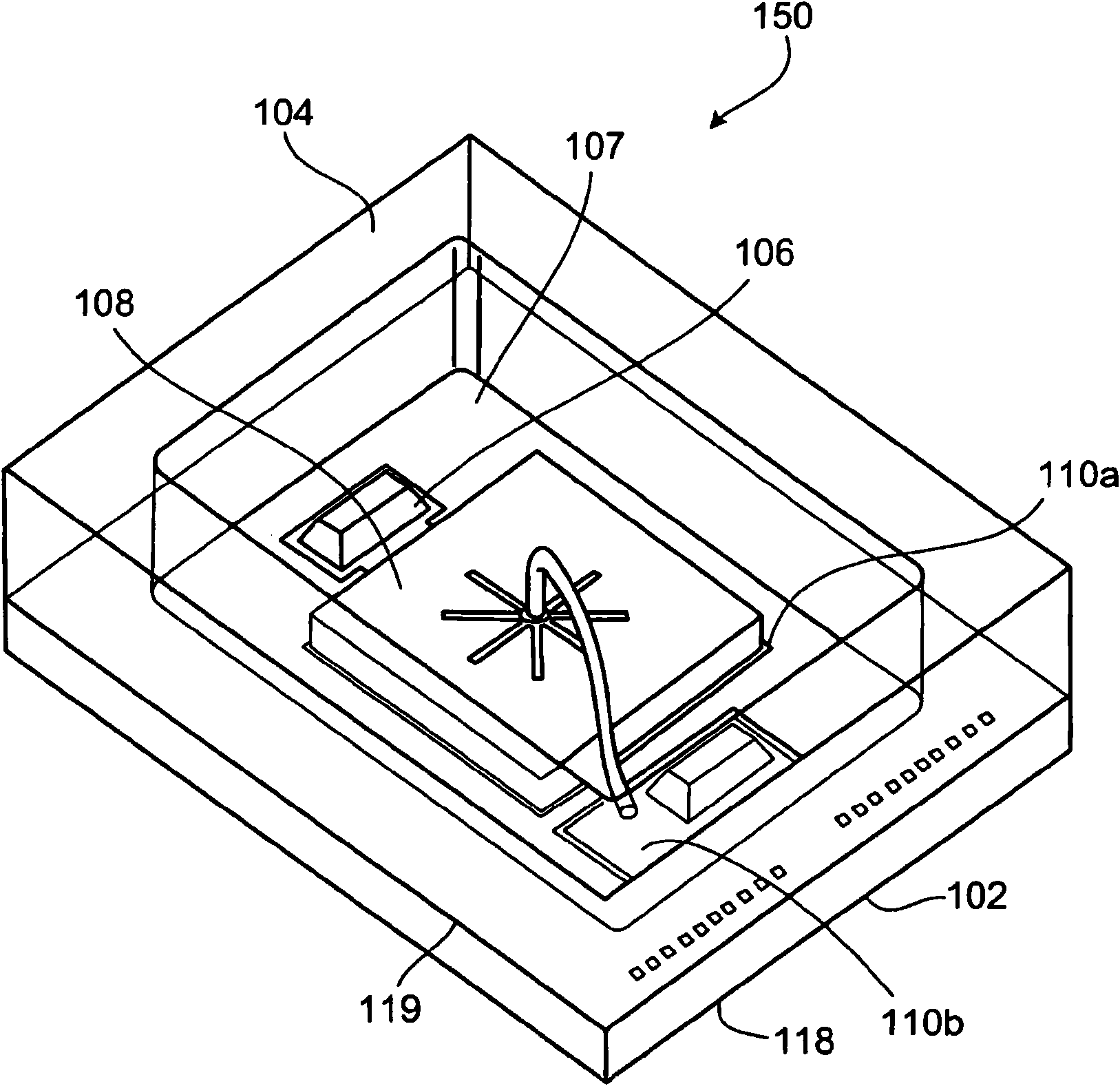

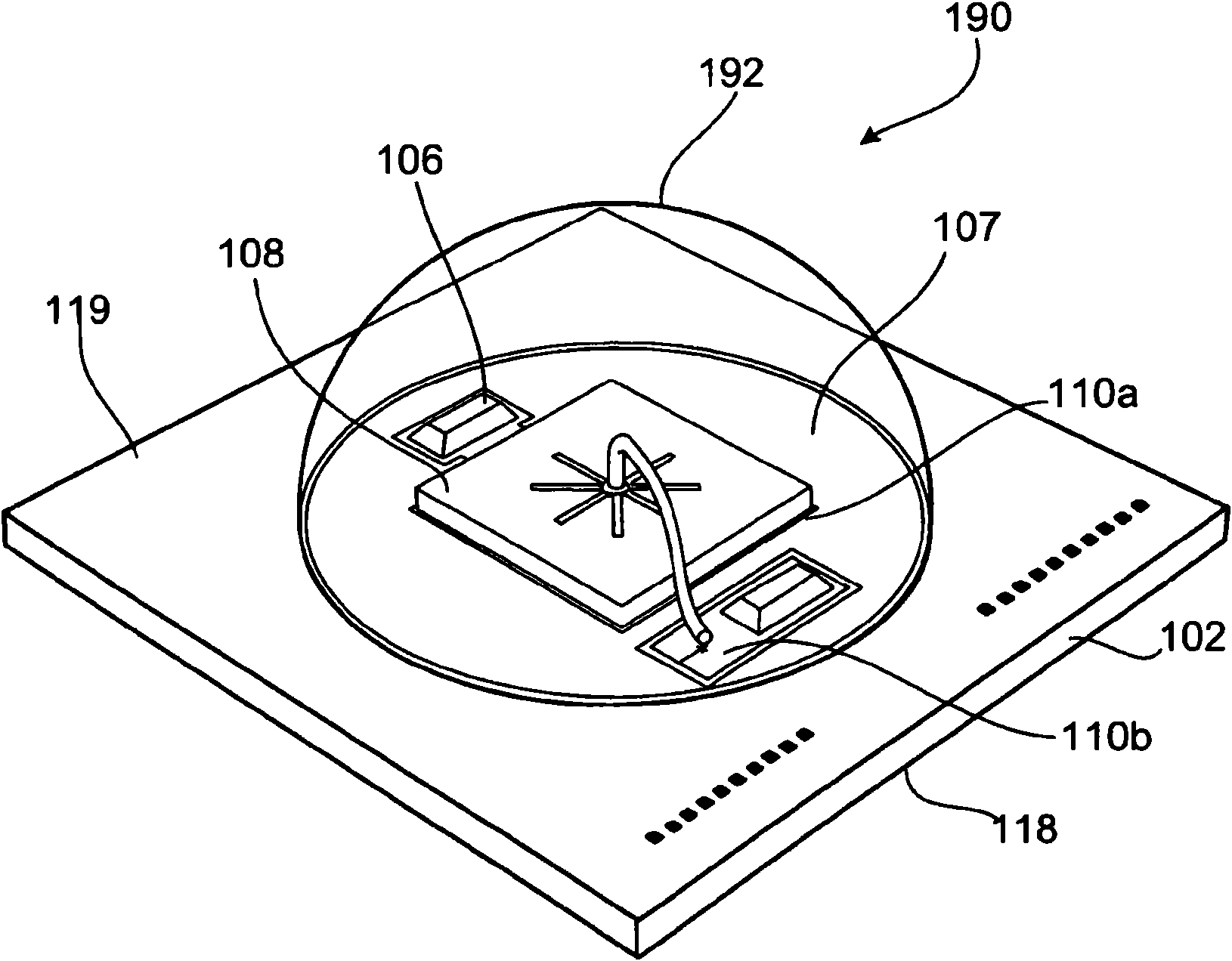

[0031] Figure 1a and Figure 1b Examples of thin LED packages 100 and 150 with enhanced thermal characteristics 100 and 150 are shown. Although Figure 1a and Figure 1b It is described relative to a light emitting diode 108, but the light emitting diode 108 can be replaced by other types of optoelectronic components. For example, in some applications, the LED 108 can be an infrared emitter (such as a vertical cavity surface emitting laser), an infrared receiver (such as a pin diode) or an infrared transceiver (infra-red transceiver). replace. Likewise, the manufacturing process described below can be used for the manufacture of encapsulations for optoelectronic components other than light-emitting diodes.

[0032] The LED package 100 includes a substrate 102, a reflector 104, a conductive metallization 106, a reflective surface 107, an LED 108, an LED die attach pad 110a (located below the LED 108) and The wire bonding pads 110b. In the illustrated example, substrate 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com