Vertical lifting hydraulic hanging mechanism

A hydraulic suspension and vertical lifting technology, which is applied in the field of hydraulic suspension mechanism and vehicle suspension device, can solve the problems of reducing the service life of tires, increasing the lateral wear between tires and the ground, which is not conducive to cost saving for users, and achieves reducing friction, The effect of ensuring safety and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

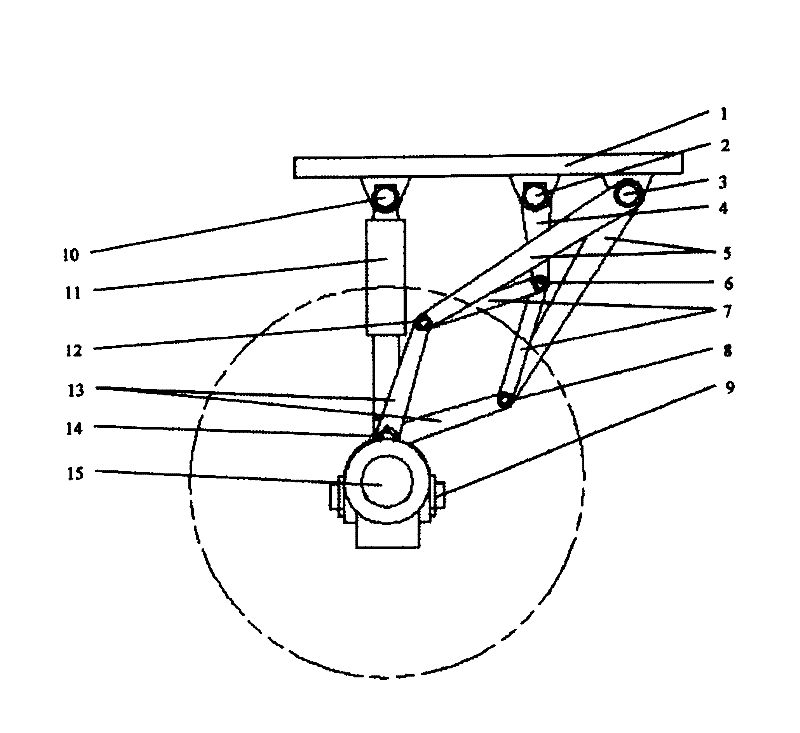

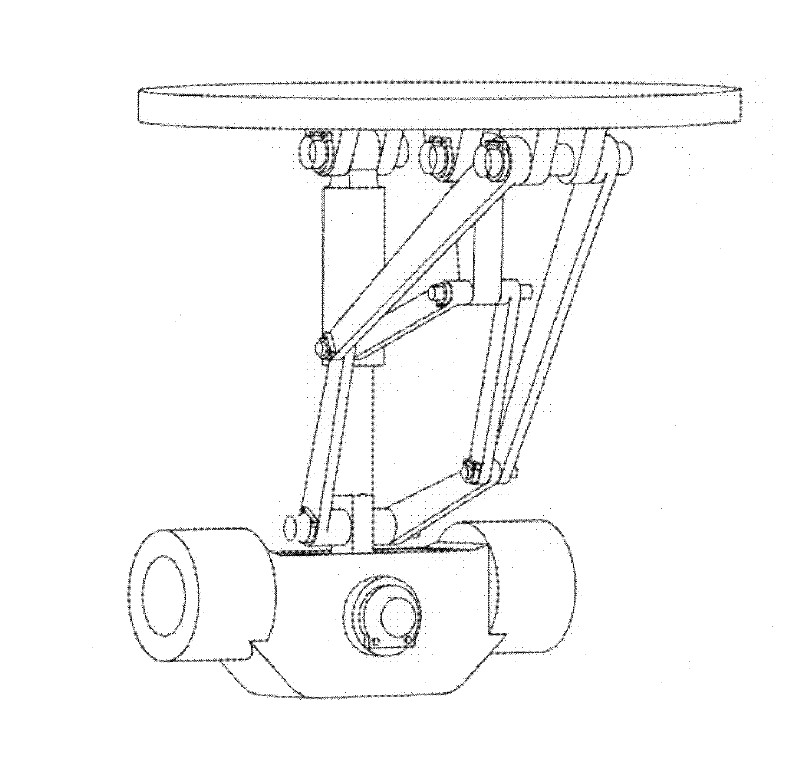

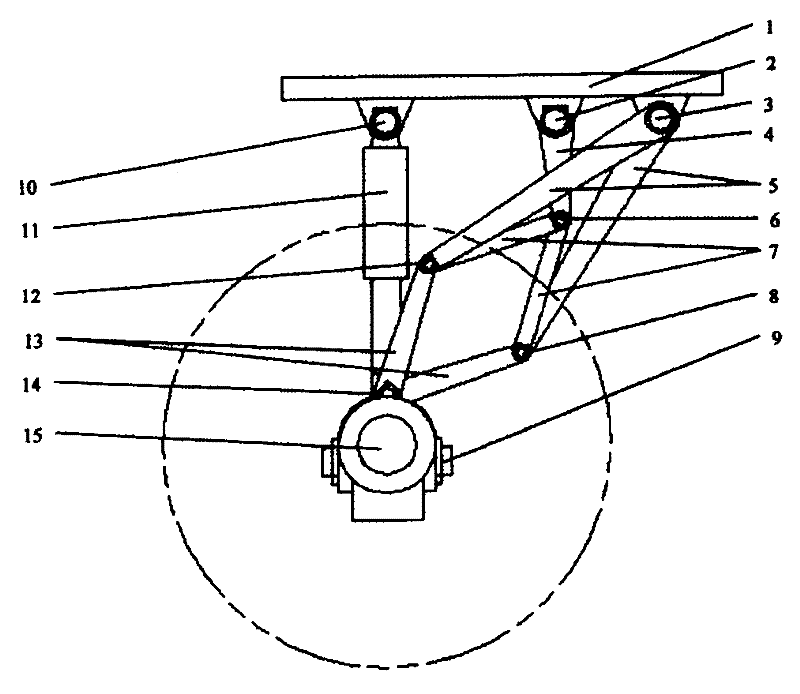

[0014] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] Please also see figure 1 and figure 2 The structure diagram of the present invention shows that the hydraulic suspension mechanism for vertical lifting is arranged on the lower part of the motor vehicle. The vertical lifting hydraulic suspension mechanism comprises a suspension frame 1, a hydraulic cylinder 11, an axle body 15, a short connecting rod 4, a pair of first middle connecting rods 7, a pair of second middle connecting rods 13 and a pair of long connecting rods 5 , wherein, a pair of first middle connecting rods 7 and a pair of second middle connecting rods 13 have the same length.

[0016] The suspension frame 1 is a plate-shaped member, its upper top surface is connected with the lower plane of the motor vehicle through a slewing bearing, and the lower end surface of the suspension frame 1 is connected to the upper end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com