Silencer

A muffler and cylinder technology, applied in the direction of mufflers, machines/engines, engine components, etc., can solve the problems of unsuitable capsule dismantling equipment, inconvenient disassembly and internal cleaning, and inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

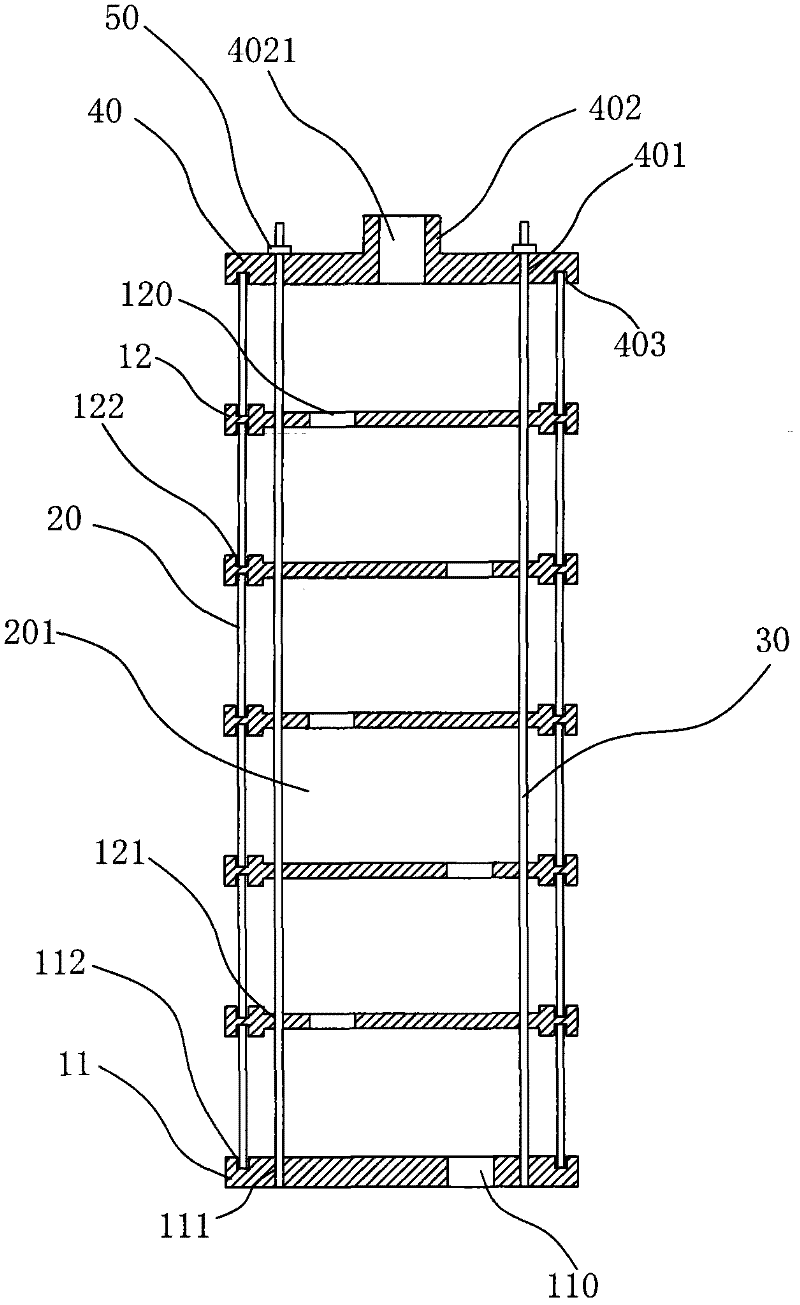

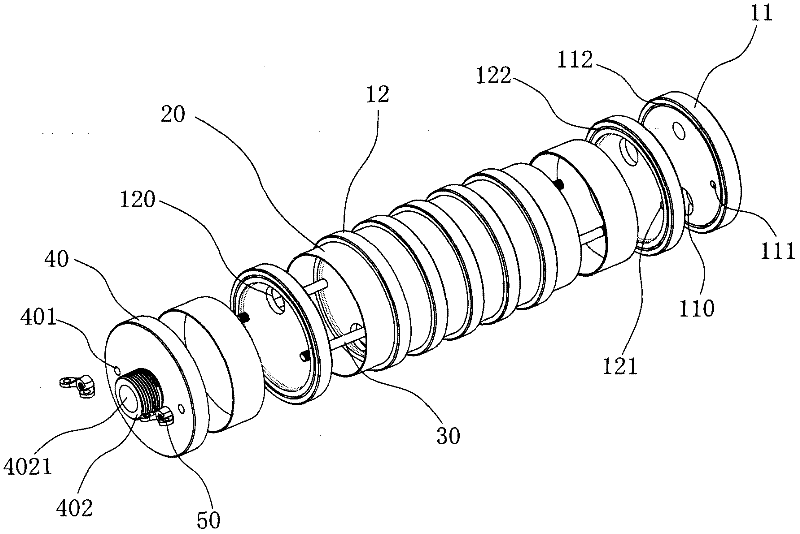

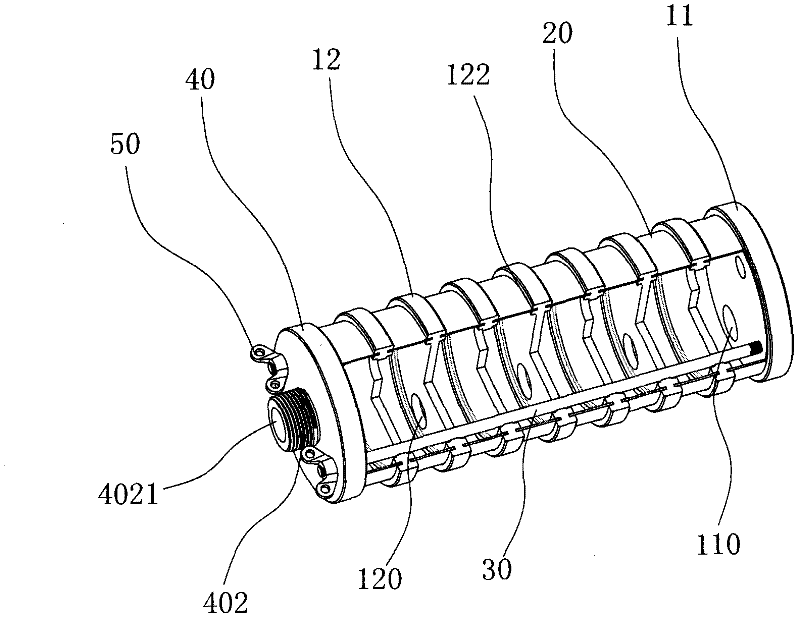

[0017] Such as Figure 1-3 In the shown embodiment, the muffler includes a connection cover 40, a bottom disc 11, a multi-section annular cylinder 20 between the connection cover 40 and the bottom disc 11, and the connection cover 40 has a An externally threaded connecting rod 402 that is detachably connected to the application equipment. The externally threaded connecting rod 402 has external threads for easy detachable connection with the application equipment. Of course, other methods can also be used to detachably connect the connection cover 40 to the application equipment, such as setting a flange on the connection cover and connecting the application equipment through the flange. This is also a common connection method and will not be described here. repeat.

[0018] In this embodiment, the multi-section cylinders 20 are connected in series, and the cylinder 20 at the top and the cylinder 20 at the bottom are respectively connected with the connection cover 40 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com