Method for calibrating pushing force of trial run table inside engine room

A test bench and engine technology, applied in the field of aero-engines, can solve the problems of unstable performance, difficult implementation, and regulations on the calibration of military aero-engine indoor test benches, etc., to achieve major military and economic benefits, and reduce performance instability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A method for calibrating thrust of a test bench in an engine room, comprising the steps of:

[0015] Step 1: According to the theoretical thrust requirements of the engine design, draw the maximum state theoretical thrust index tolerance zone and the full afterburner state theoretical thrust index tolerance zone at the corresponding atmospheric temperature;

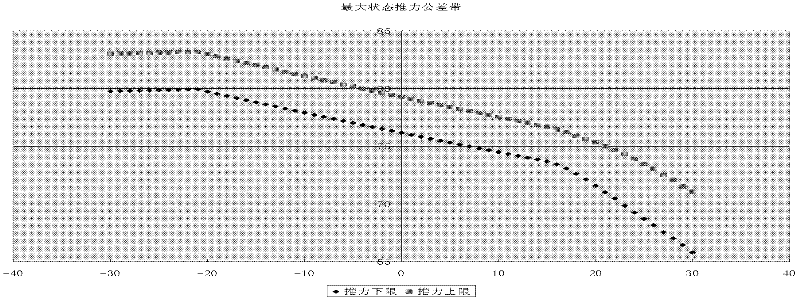

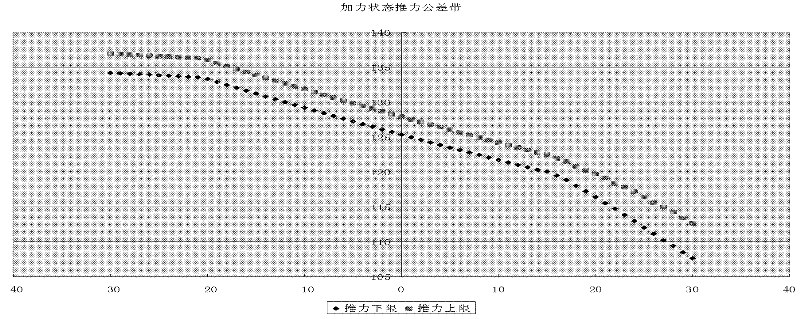

[0016] Step 2: Use the thrust conversion coefficients of the maximum state and the augmented state to calculate the theoretical thrust values of the maximum state and the full augmented state at the corresponding atmospheric temperature, and then according to the maximum state thrust limit value tolerance and the full augmented state thrust limit value tolerance, Draw the theoretical thrust tolerance curve of the maximum state and the theoretical thrust tolerance curve of the full afterburner state, such as figure 1 and figure 2 shown;

[0017] Step 3: Draw the thrust measurement value of the test bench into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com