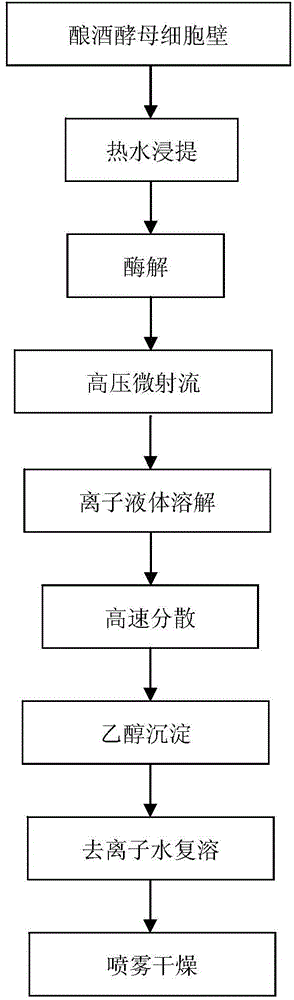

Method for preparation of yeast beta-D-glucan by utilization of molecular assembly solubilizing technology

一种葡聚糖、酵母的技术,应用在酵母β-D-葡聚糖的制备,高纯度的酵母β-D-葡聚糖领域,能够解决葡聚糖溶解度低、限制实际应用、限制生物活性等问题,达到制备条件温和、重大经济效益和环保意义、扩大应用范围的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) adding deionized water to the cell wall of Saccharomyces cerevisiae, stirring to obtain a suspension, centrifuging and washing until the supernatant is clear, and collecting the precipitate;

[0041] (2) Add deionized water to the precipitate described in step (1), prepare a solution with a concentration of 15% (w / v) in g / mL, and extract it in a constant temperature water bath shaker at 95°C for 4h , centrifuge at 4500rpm for 10min to collect the precipitate, wash the precipitate twice with water, and centrifuge again at 4500rpm for 10min to collect the precipitate;

[0042] (3) Add deionized water to the precipitation described in step (2) to prepare a solution with a concentration of 20% (w / v) in g / mL, add helicase to the solution for enzymolysis, and enzymolysis conditions The method is: temperature 40°C, addition amount 0.01%, time 3h; then treat at 80°C for 10 minutes, carry out enzymatic inactivation treatment, and obtain enzymatic hydrolyzate;

[0043] (4) T...

Embodiment 2

[0051] (1) adding deionized water to the cell wall of Saccharomyces cerevisiae, stirring to obtain a suspension, centrifuging and washing until the supernatant is clear, and collecting the precipitate;

[0052] (2) Add deionized water to the precipitation described in step (1), prepare a solution with a concentration of 25% (w / v) in g / mL, and extract it in a constant temperature water bath shaker at 95°C for 4h , centrifuge at 5000rpm for 5min to collect the precipitate, wash the precipitate twice with water, and centrifuge again at 5000rpm for 5min to collect the precipitate;

[0053] (3) Add deionized water to the precipitation described in step (2) to prepare a solution with a concentration of 15% (w / v) in g / mL, add neutral protease to the solution for enzymolysis, and enzymolysis The conditions are: temperature 45°C, addition amount 0.05%, time 1h; then treat at 80°C for 10 minutes, carry out enzyme inactivation treatment, and obtain enzymatic hydrolysis solution;

[0054...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com