Fabricated arched channel made of ultra-high-performance concrete

An ultra-high performance, concrete technology, used in tunnels, tunnel linings, shaft equipment, etc., can solve the problems of small span and heavy structure, and achieve the effect of reducing the weight of the structure, high construction level, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

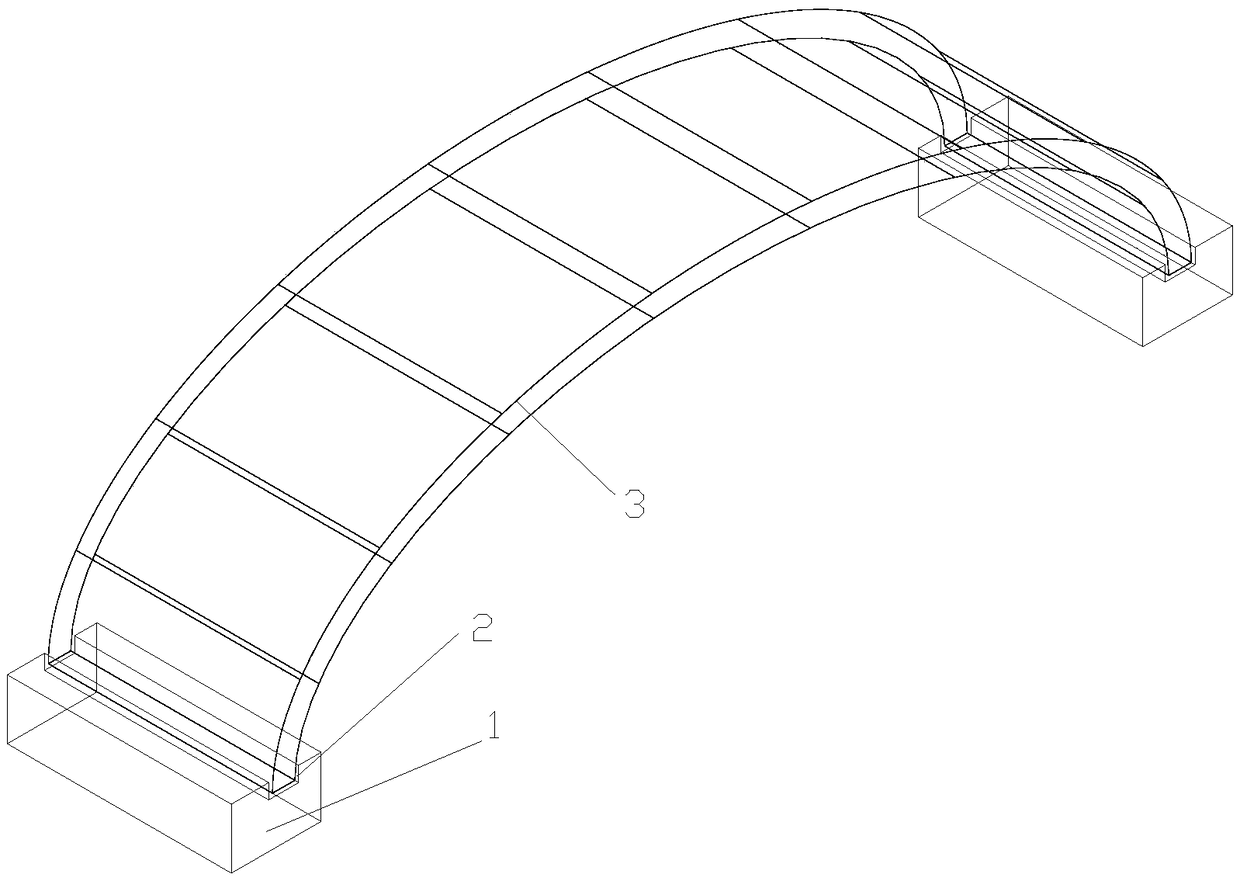

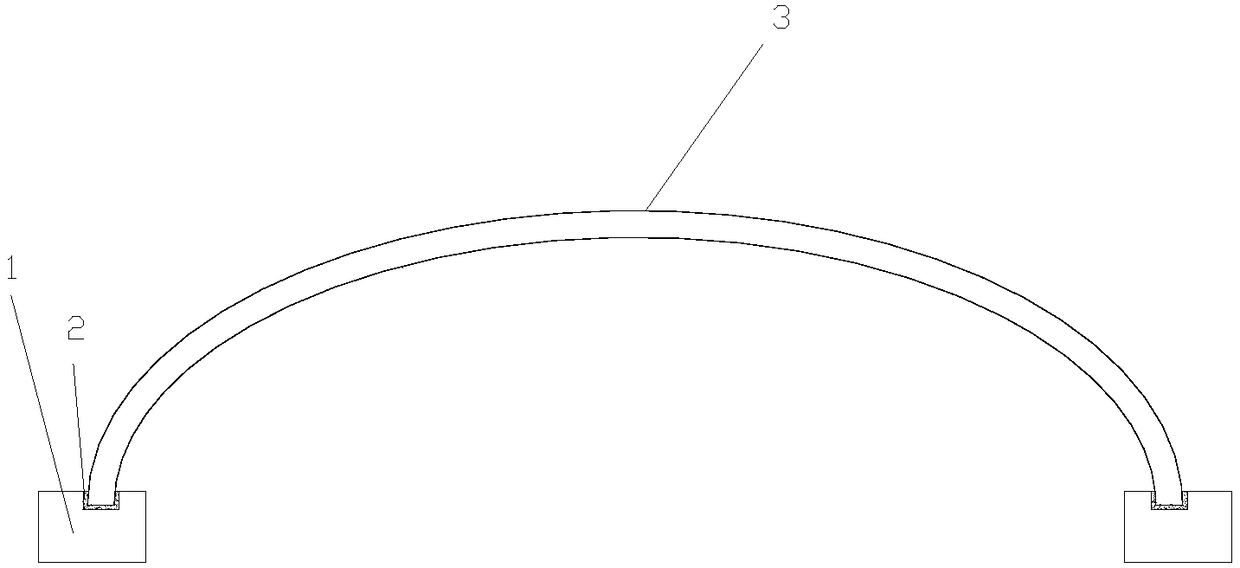

[0034] Embodiment 1: It is suitable for the span channel structure below 12m, and the prefabricated arch piece is 1 / 2 oval.

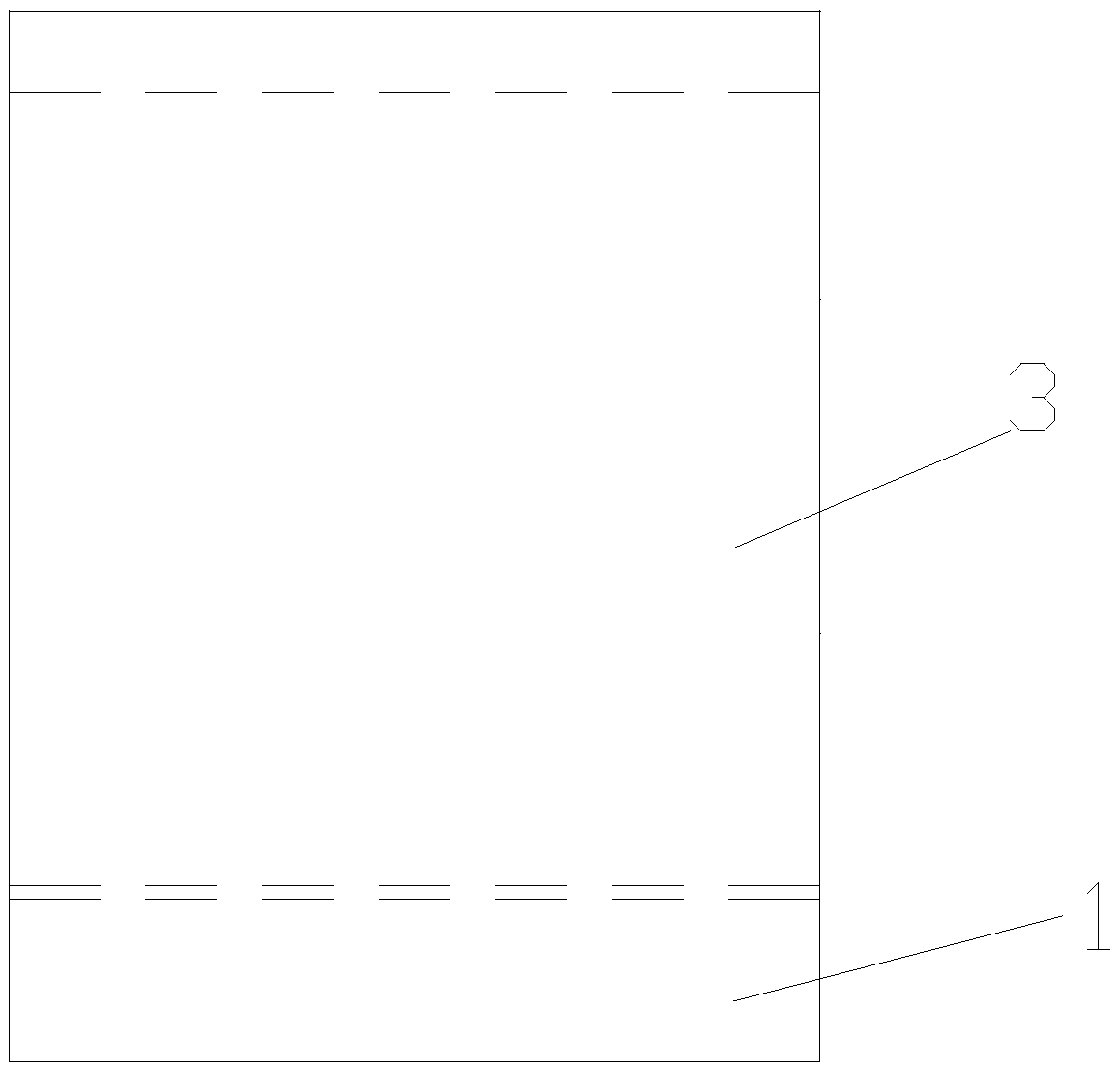

[0035] A prefabricated ultra-high-performance concrete arched channel, including a prefabricated foundation 1, an installation groove 2 is arranged on the prefabricated foundation, a prefabricated arch piece 3 is installed in the installation groove, the prefabricated arch piece is made of ultra-high performance concrete, and the prefabricated foundation is made of ordinary concrete , the thickness of the prefabricated arch plate is 0.15m~0.35m, the segment length is 2~3m, the width of the installation groove is 10cm larger than the width of the arch piece, and the depth is 20cm. The installation groove is filled with a higher grade of ultra-high performance concrete to form a whole. And do waterproof treatment.

Embodiment 2

[0036] Embodiment 2: On the basis of Embodiment 1, the present invention proposes another embodiment: for a 12m-20m span channel structure, there are two prefabricated arches 3, and the prefabricated arches are 1 / 4 oval.

[0037] Including the prefabricated foundation 1, there is an installation groove 2 on the prefabricated foundation, the prefabricated arch piece 3 is installed in the installation groove, the end face of the joint connected by the prefabricated arch piece is provided with a toothed shear key 4, and a notch 5 is reserved in the middle of the joint, and the notch Reserve 5cm thick bottom support at the bottom6.

[0038] The tooth-shaped shear keys are bonded together by epoxy resin, and the epoxy resin between the shear keys is spread evenly, with a thickness of 2-3mm.

[0039] Bolt holes 7 are reserved on both sides above the joints where the prefabricated arch pieces are connected, and the two prefabricated arch pieces are connected by crossing bent bolts 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com