Method for measuring fracture toughness of interface between hard film and soft foundation

A fracture toughness and hard film technology, which is applied in the field of measuring the fracture toughness of the hard film and soft substrate interface, can solve the problems of soft substrate deformation and lower test accuracy, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The method for measuring the interface fracture toughness of flexible electronic devices provided by the present invention will be further described below in conjunction with the accompanying drawings. The method includes the following steps:

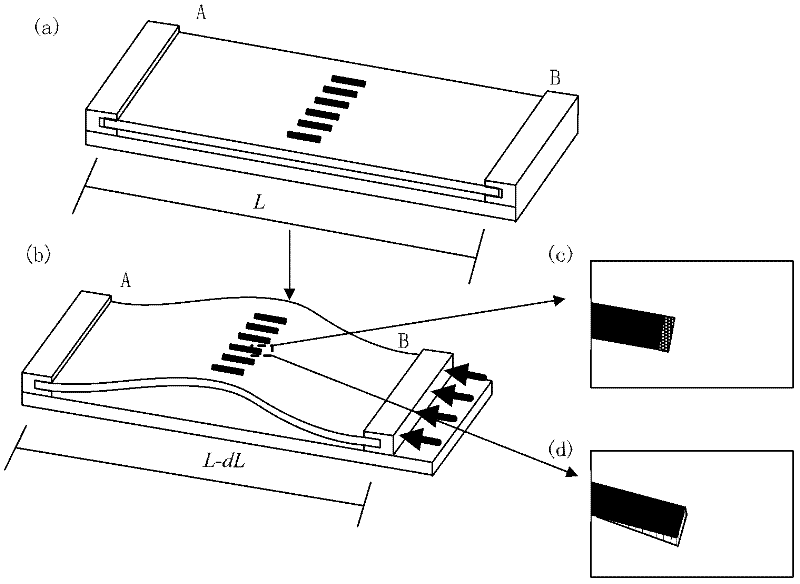

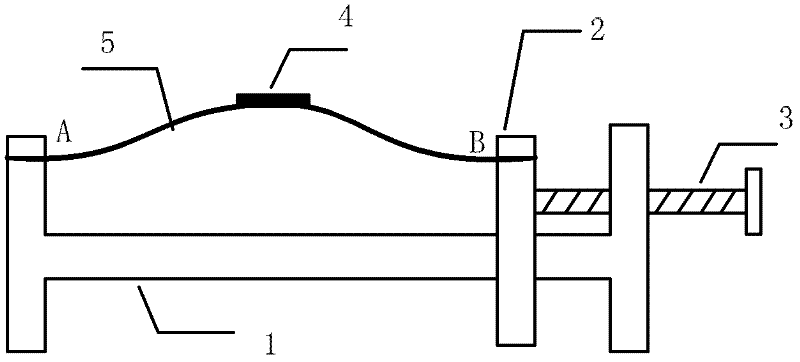

[0020] 1). Place the soft substrate with a hard film on the plate horizontally, fix the A end of the soft substrate, and allow the movement of the B end in the horizontal direction (such as figure 1 Shown in (a), record the original length L of soft base 5;

[0021] 2). Apply horizontal pressure to end B of the soft base, causing the soft base to buckle upwardly ( figure 1 As shown in (b), at this time, the upper surface of the soft substrate is subjected to tensile stress, which makes the interface between the hard film and the soft substrate tend to debond or slip. Continue to apply pressure and observe the interface between the hard film and the soft substrate in real time until debonding or slippage occurs. Record the compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com