Wafer Bow Measurement Method

A technology of curvature and wafer thickness, applied in the field of wafer curvature measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

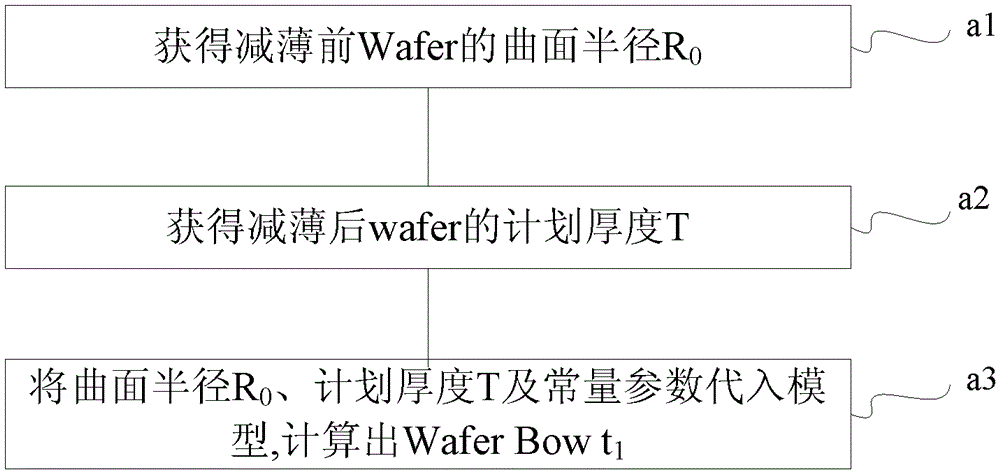

[0011] Combine below figure 1 A specific implementation is given.

[0012] Step a1, obtain the surface radius R of the Wafer before thinning 0 , the surface radius R 0 It can be directly measured and obtained by the film stress measuring machine.

[0013] In step a2, the planned thickness T of the thinned wafer is obtained, which is the thickness of the thinned wafer set by the process and is related to the specific process.

[0014] Step a3, the surface radius R 0 , planned thickness T and constant parameters are substituted into the model, [R 0 T 2 -(R 0 2 T 4 -r 2 T 0 4 ) 1 / 2 ] / T 0 2 +C(T 0 / T) 1.58 Calculate WaferBowt 1 , where T 0 In order to reduce the thickness of the wafer, r is the radius of the wafer, and C is the curvature of the wafer caused by the gravity of the wafer before thinning. For a wafer of a specific size, its value is a constant, for example, for an 8-inch wafer, C is about 0.11, and there are corresponding C values for 6-inch and 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com