Anti-loosening socket of electrical plug connector of wheel speed sensor

A wheel speed sensor and electric plug technology, which is applied to the parts, connections, circuits and other directions of the connecting device, can solve the damage of interference fit, the failure of the automobile wheel speed sensor, and the unreasonable structural design of the electric plug connector of the automobile wheel speed sensor. and other problems to achieve the effect of eliminating vibration and reducing failure defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

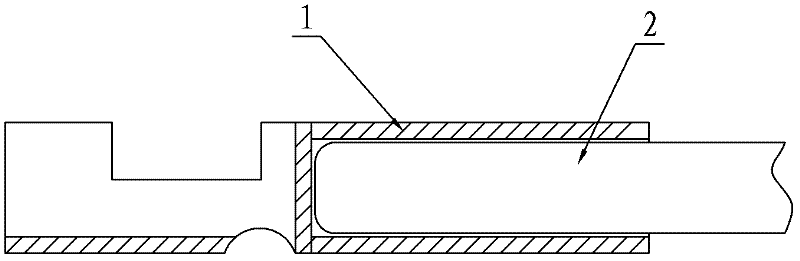

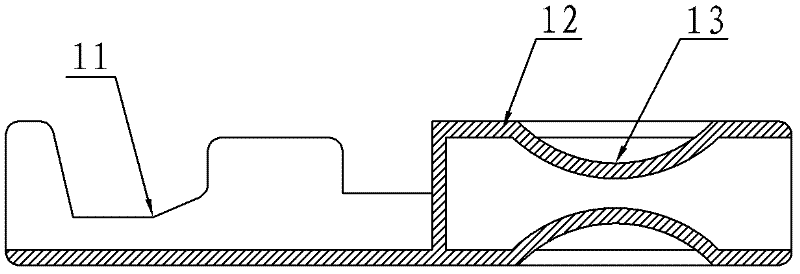

[0013] The anti-loosening socket of the electrical plug connector of the wheel speed sensor, such as image 3 As shown, it includes an electrode socket socket 1 and a cylindrical electric socket core 2. The electrode socket socket 1 includes a connection handle 11 and an electric socket socket 12, and the socket handle 11 and the electric socket socket 12 are connected as a whole, Three concave elastic cards 13 are uniformly arranged on the circumferential side wall of the electric ferrule sleeve 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com