Manufacturing method of starch pearls

A manufacturing method and technology for powder balls, which are applied in the field of making powder balls to achieve the effect of diversifying taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to understand the technical features and practical effects of the present invention in detail, and to implement them according to the contents of the description, the preferred embodiment shown in the accompanying drawings will be described in detail as follows:

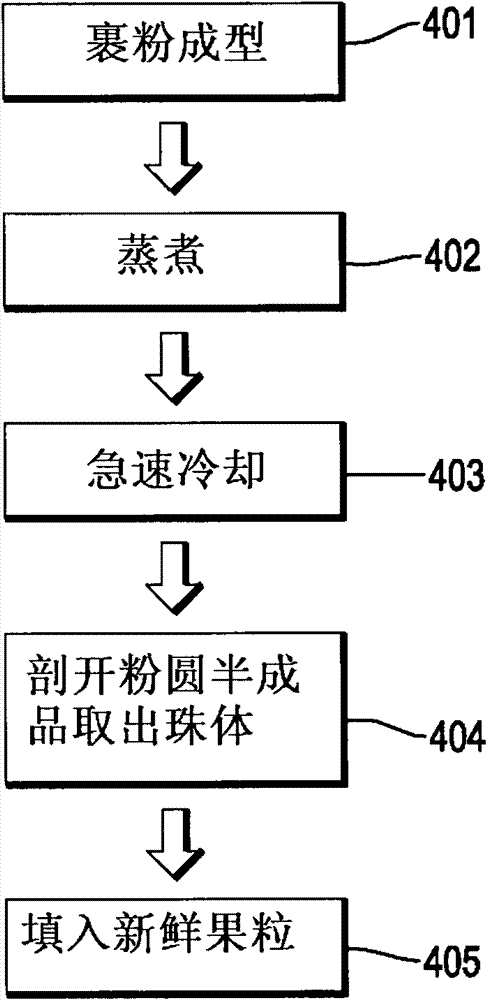

[0024] The preferred embodiment of the manufacturing method of the powder circle provided by the present invention is as follows: figure 1 and figure 2 shown, including the following steps:

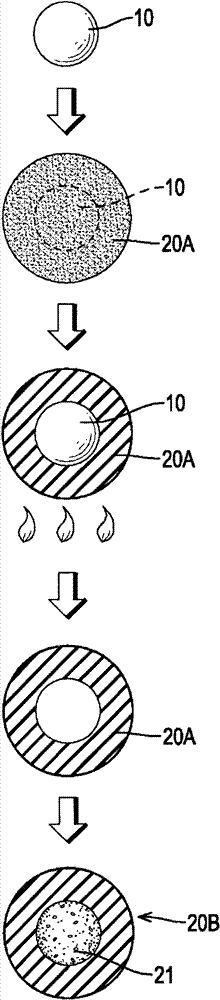

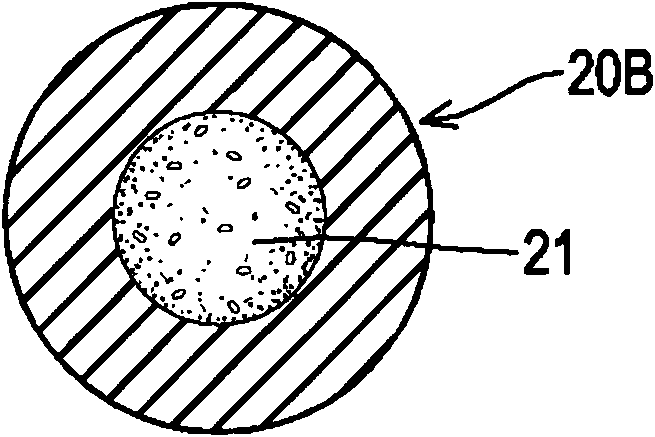

[0025] Powder-wrapping forming step 401: After a plurality of beads 10, such as stainless steel beads, are wetted, the surface of the plurality of beads 10 is coated with powdered raw materials, such as starches such as sweet potato flour or tapioca flour, to form a plurality of powders. Round semi-finished products 20A;

[0026] Cooking step 402: steaming the plurality of round semi-finished products 20A;

[0027] Rapid cooling step 403: rapidly cooling the steamed semi-finished powder balls 20A, and then a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com