Punching machine

A technology of machinery and indenters, applied in the field of stamping machinery, can solve the problems of complex structure, difficult adjustment, large number of parts, etc., and achieve the effect of preventing co-rotation and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

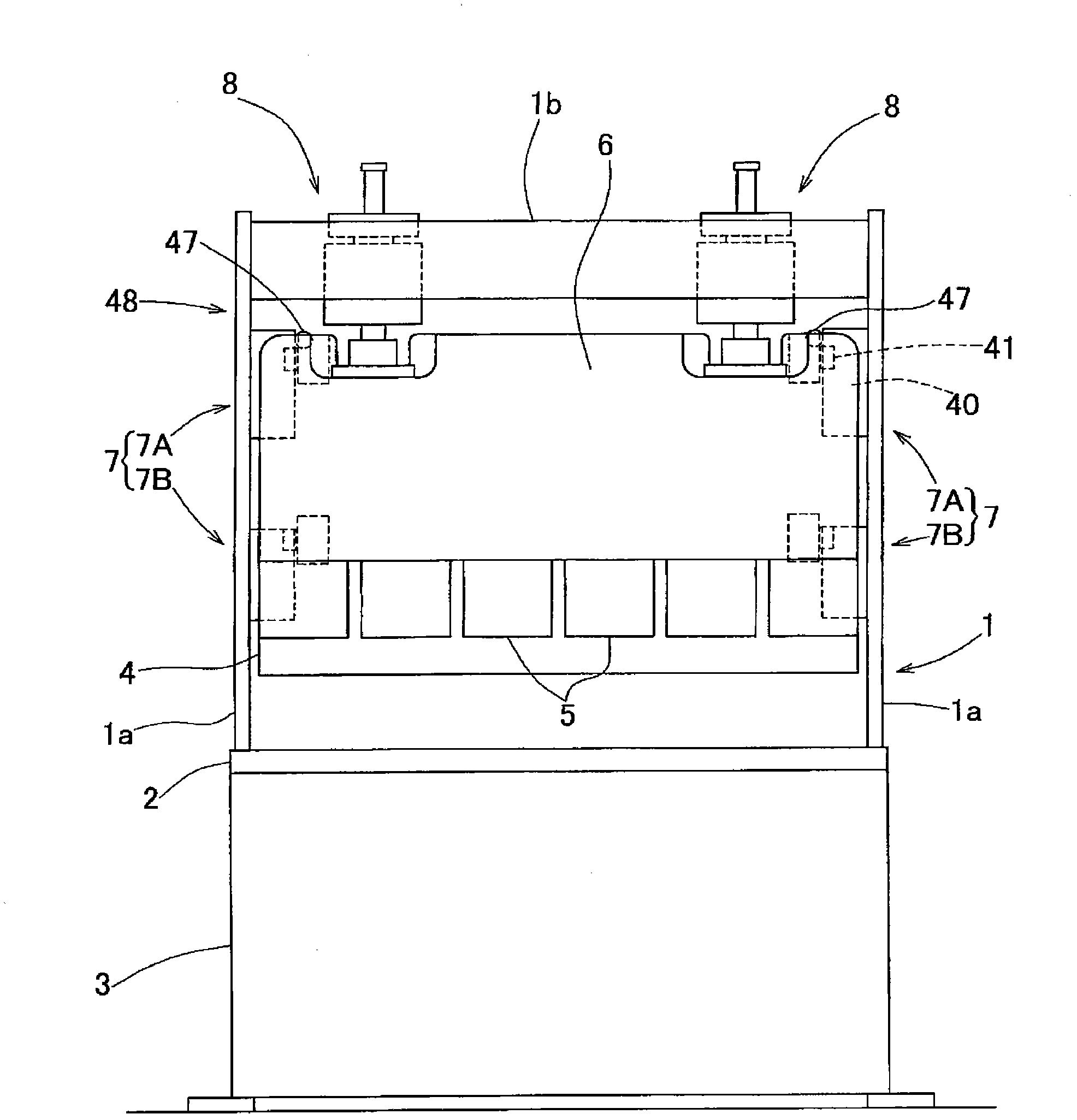

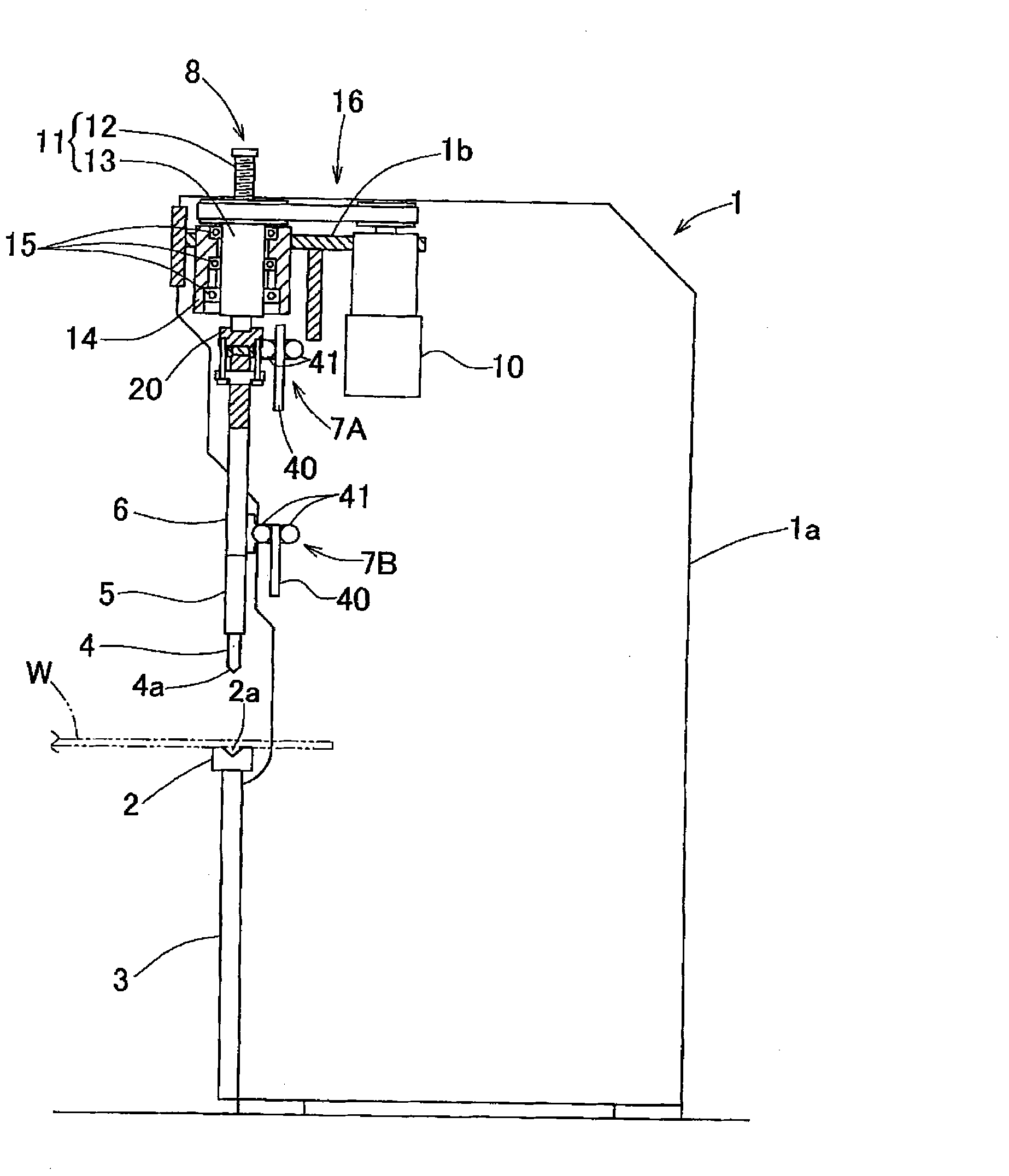

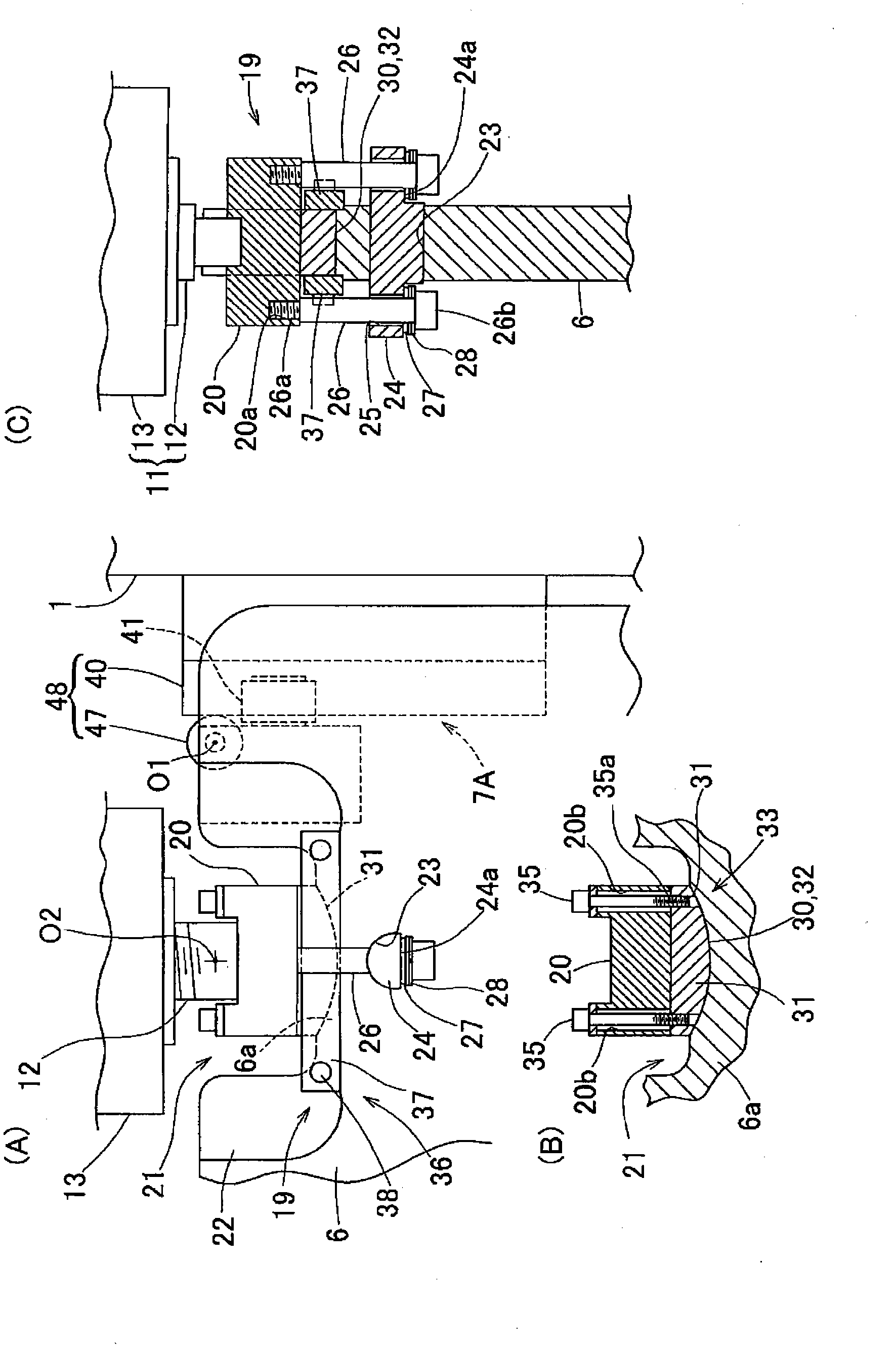

[0026] An embodiment of the present invention will be described with reference to the accompanying drawings. figure 1is a front view of the press machine according to this embodiment, figure 2 is its partially cut side view. This press machine is a plate bender. On the front side of the main body frame 1, a table 3 supporting a lower die 2 which is a fixed die and a ram 6 supporting an upper die 4 which is a movable die are provided. The workbench 3 is fixed relative to the main body frame 1 . Therefore, the lower mold 2 is set on the main body frame 1 via the table 3 . The indenter 6 is vertically supported by the main body frame 1 by the vertical guide mechanism 7 on the left and right sides, and is independently driven by the left and right sides by the left and right pair of vertical drive mechanisms 8 . The main body frame 1 includes: a pair of left and right side plates 1a; and a connecting frame portion 1b connecting the upper parts of the left and right side plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com