Tread pattern on tires for passenger car

A technology for tread patterns and car tires, which is applied to tire treads/tread patterns, tire parts, vehicle parts, etc., can solve problems such as not being able to meet the needs of the international market, achieve good high-speed control stability, increase length, The effect of pattern block stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

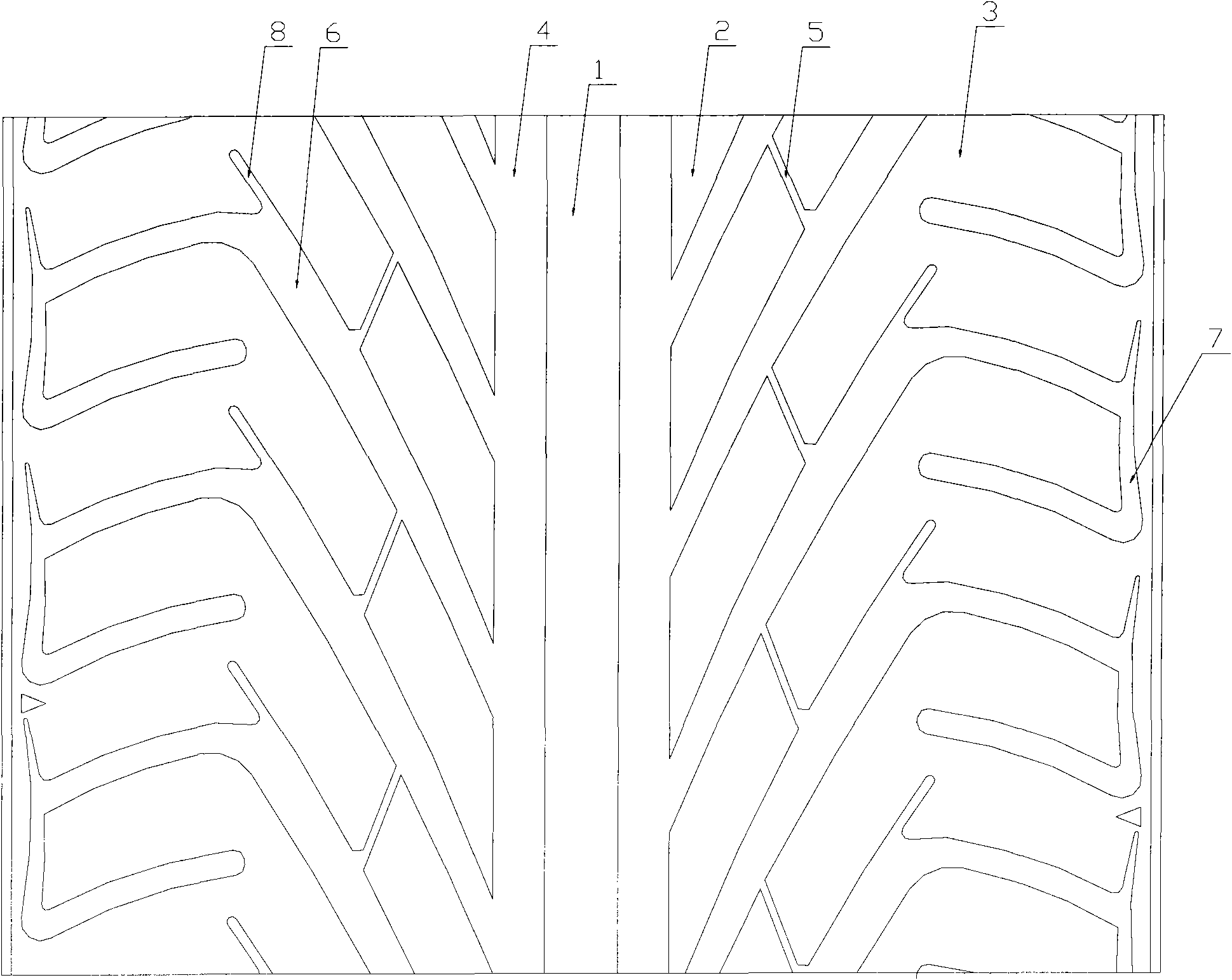

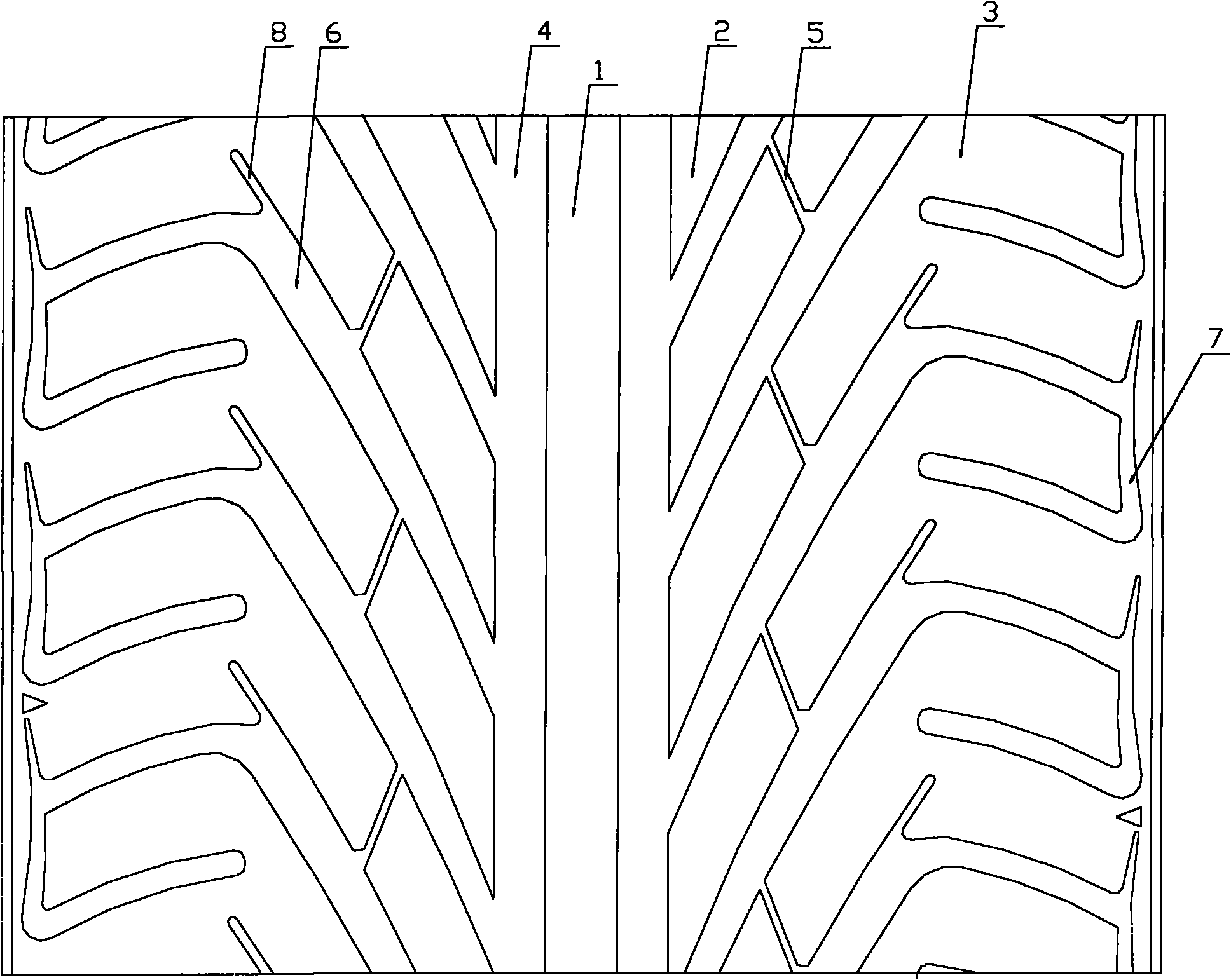

[0016] The tire tread of the present invention includes a central pattern block 1, side pattern blocks 2, and shoulder pattern blocks 3, the central pattern block 1 is located in the center of the tread, and the side pattern blocks 2 are regularly arranged in sequence on the left and right sides of the tread from inside to outside. 1. The shoulder pattern block 3, the central pattern block 1 is an integrated longitudinal pattern block, the central pattern block 1 and the side pattern block 2 are separated by longitudinal circumferential grooves 4; the side pattern block 2 and the shoulder pattern block 3 The intervals are separated by auxiliary longitudinal grooves 5; the intervals between adjacent side blocks 2 and adjacent shoulder blocks 3 are separated by lateral grooves 6, and the lateral grooves 6 are connected to the longitudinal circumferential grooves 4 , both ends of the auxiliary longitudinal groove 5 communicate with two adjacent lateral grooves 6 respectively.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com