Pressure medium-operated cabin brake and valve arrangement for controlling the emergency brake function of the pressure medium-operated cabin brake of a lift system

A pressure medium, emergency braking technology, used in elevators, lifting equipment in mines, transportation and packaging, etc., can solve the problem of not knowing the combination of spring-mass-system, and achieve the effect of reliable braking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

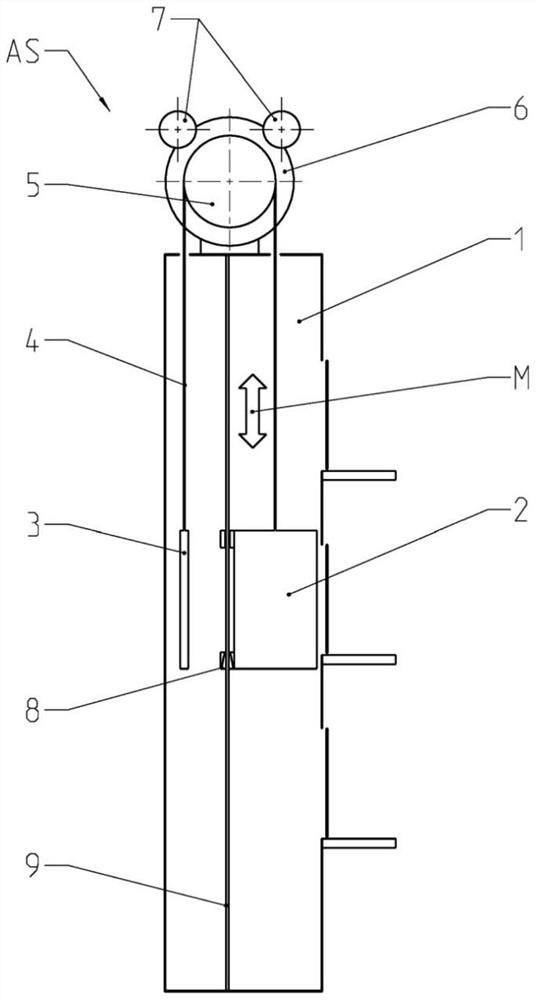

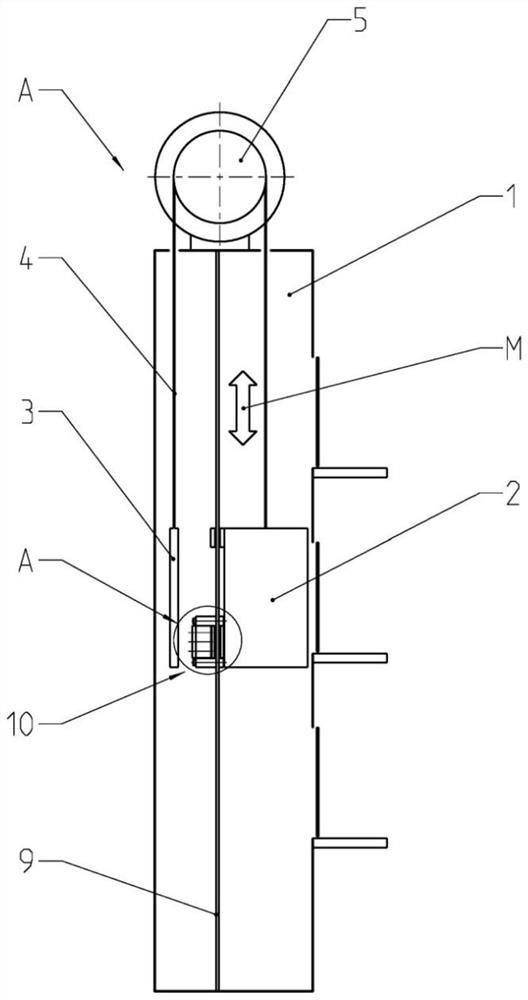

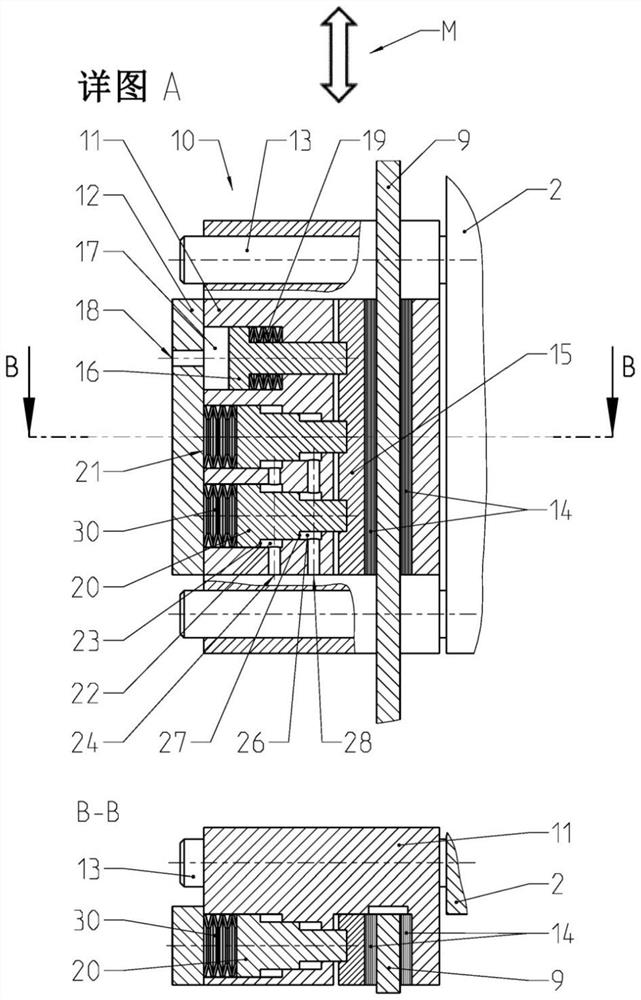

[0032] exist figure 1 shows the principle construction of an elevator according to the prior art in a guide wheel configuration with a rope transmission ratio of 1:1. A passenger cabin (2) and a counterweight (3) are arranged in the elevator shaft (1) and are connected to each other via a spreader (4). The spreader (4), which may consist of a rope set or a belt, is deflected by and frictionally engaged with guide wheels (5). The vertical movement of the cabin (2) and the counterweight (3) in the elevator shaft (1) in the direction of travel (M) is achieved by rotating a guide wheel (5) connected to the motor.

[0033] In passenger lifts according to the prior art, in order to ensure the braking and stopping of the cabin (2) and the counterweight (3), there are two braking systems independent of each other:

[0034] - a first brake system (7) acting directly on the brake disc (6) connected to the guide wheel (5) and in this example for redundancy purposes the first brake syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com