Raw tobacco automatic storage and conveying process

An automatic and technological technology, applied in the field of storage and conveying technology in the tobacco industry, can solve the problems of high labor intensity of workers, large warehouse space occupation, poor information traceability, etc., which is beneficial to forklift handling, saves investment costs and improves reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

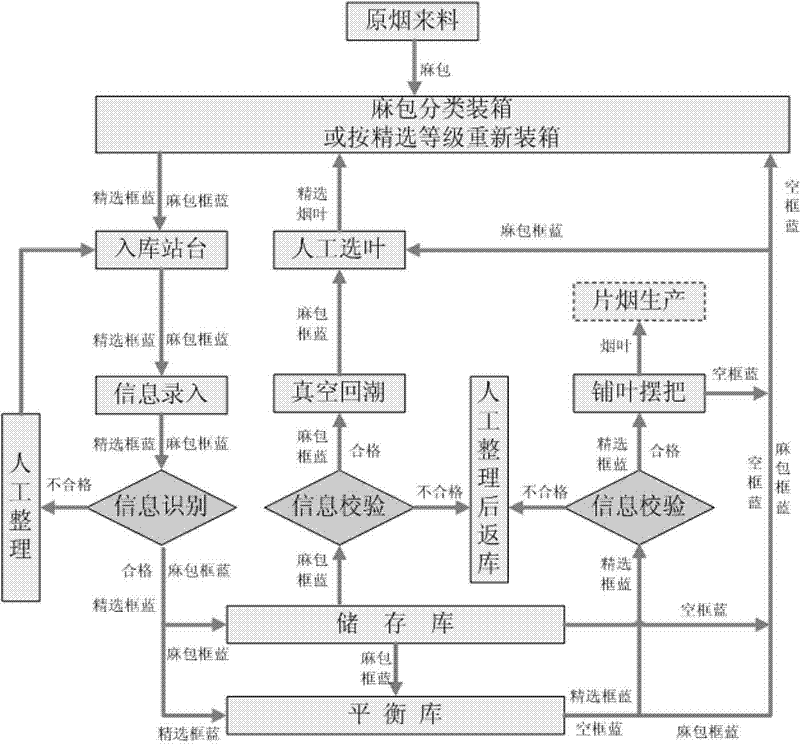

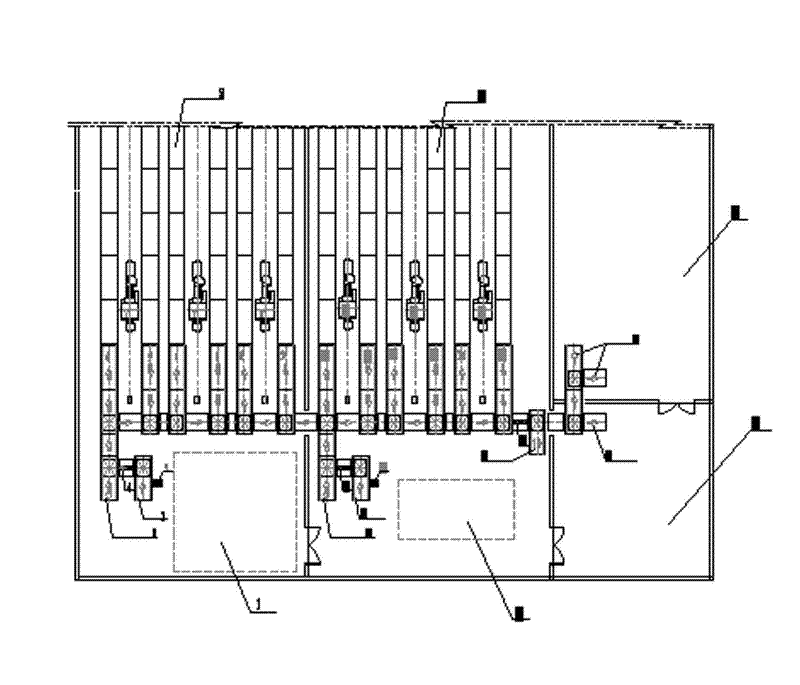

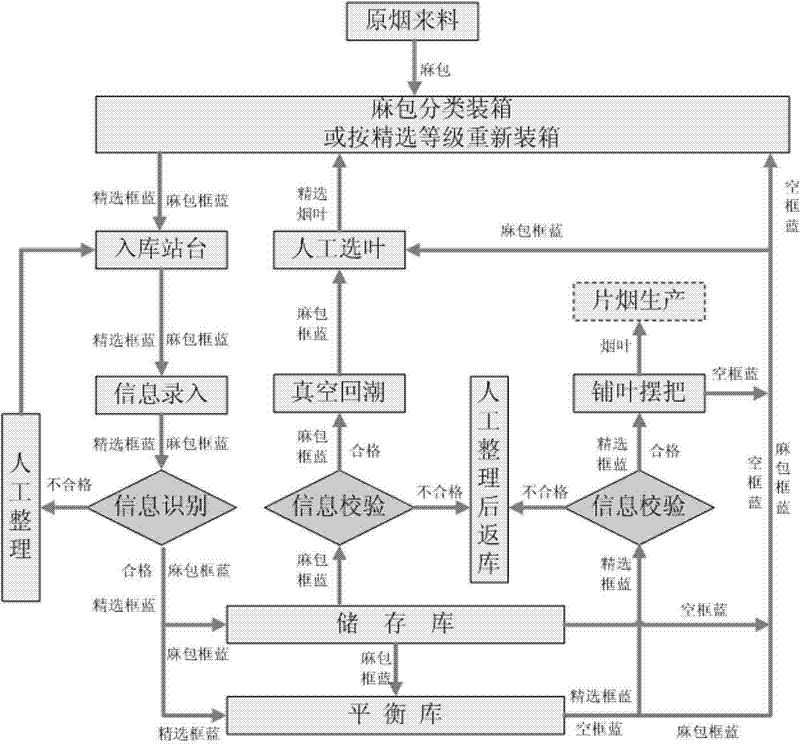

[0029] Such as figure 1 with figure 2 As shown, the standardization of the material unit of the present invention is: in order to meet the requirements of the threshing and redrying process and the logistics process, the standardization of the material is first required, and the irregular sacks are framed with a standard material carrier to form a The standard cargo unit of the information identity; the standardization of the standardization of the material unit by sub-frame blue pallets and the standardization by using flat warehouse frame blue transformation.

[0030] Standardization by using frame trays: In this invention, frame trays are used as the standard material unit carrier, and the frame trays can be folded on both sides, which is convenient for stacking and transporting empty frames; the bottom has a "two" shape The unique 4-way fork-type pallet bottom is conducive to forklift handling, logistics transportation and storage; the side of the frame is a fine mesh st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com