Aluminium Alloy Plate For Cell Box And Cell Box

A technology of aluminum alloy plates and battery boxes, which is applied to battery pack parts, circuits, electrical components, etc., can solve the adverse effects of conductivity and working voltage performance, the decrease of weld bead shape stability, and the increase of irregular weld bead incidence and other problems, to achieve the effect of excellent pulse laser weldability and excellent formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

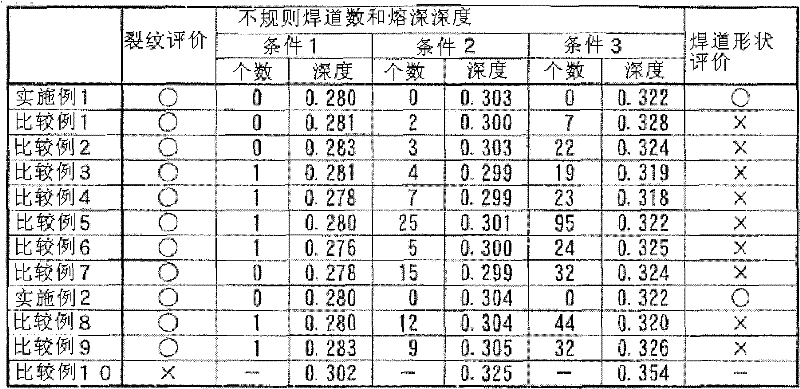

[0076][Preparation of test materials]

[0077] The aluminum alloys shown in Table 3 were subjected to the same manufacturing process as in Example 1 to obtain an aluminum alloy plate with a plate thickness of 10 mm. 【table 3】

[0078] mn

Cu

Mg

Si

Fe

Zn

Ti

B*

Al

Example 3

0.82

0.15

-

0.11

0.62

0.01

0.003

9.1

margin

Example 4

0.97

0.15

-

0.11

0.64

0.01

0.003

9.6

margin

Example 5

1.42

0.15

-

0.12

0.66

0.01

0.004

9.7

margin

Example 6

0.96

0.07

-

0.11

0.65

0.01

0.003

9.3

margin

Example 7

0.98

0.14

-

0.07

0.61

0.01

0.003

9.6

margin

Example 8

1.00

0.15

-

0.56

0.68

0.01

0.004

9.8

margin

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com