Four-lead screw lifting device

A technology of screw lifting and lifting drive, which is applied in the direction of building structure support, building structure support, construction, etc., can solve the problems of high labor intensity and low work efficiency, and achieve the effect of high lifting efficiency, high precision, stable and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

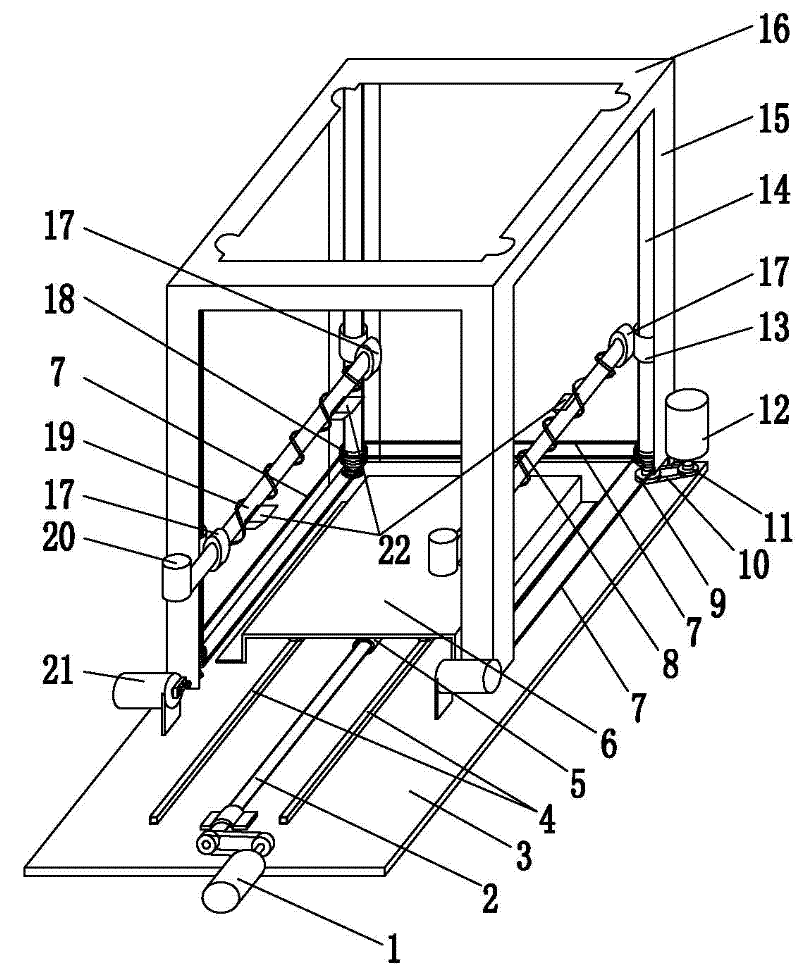

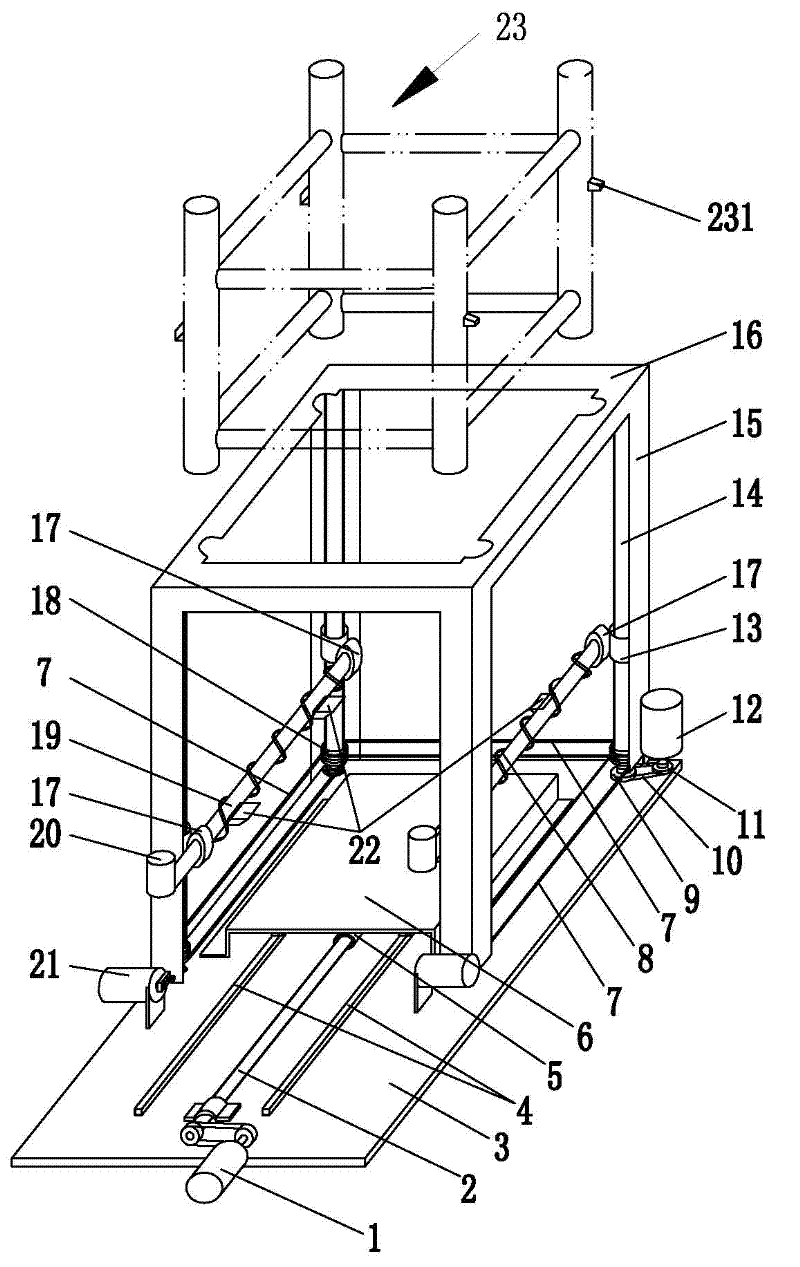

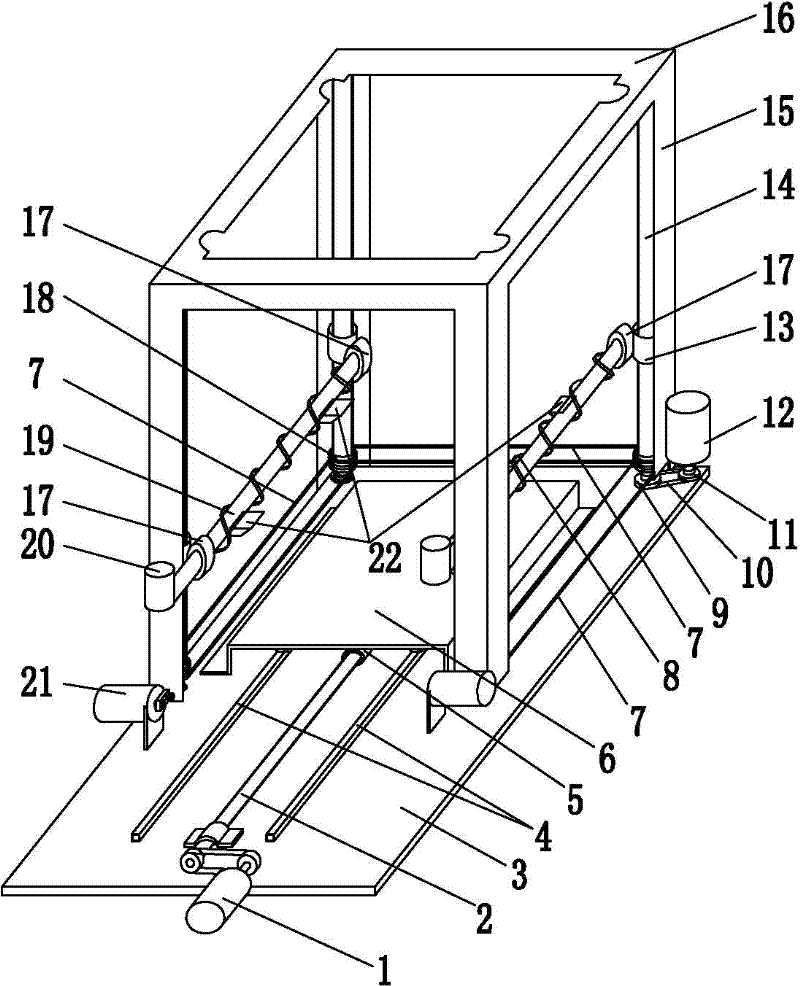

[0030] Specific embodiment 1 of the four-screw lifting device of the present invention, as figure 1 and figure 2 Shown, comprise frame 16, four screw nut mechanisms, transmission mechanism, lifting drive unit, two lifting fork 19 and two lifting fork dislocation drive units. Compared with the prior art, the present invention can realize synchronous and fast lifting of the lifting bracket 23 through the lifting drive device, four screw nut mechanisms, transmission mechanism, two lifting swing rods 19 and two lifting swing rod dislocation drive devices. And disassembly, and the adopted four-screw nut mechanism rotates synchronously through the two-stage synchronous transmission mechanism in the transmission mechanism to achieve the purpose of synchronization, stability and high precision. sinking phenomenon. It has the characteristics of high lifting efficiency, stable and reliable work, and is convenient for large-scale application and popularization in the construction fiel...

Embodiment 2

[0049] The second specific embodiment of the four-screw lifting device of the present invention, the main technical solution of this embodiment is the same as that of embodiment 1, and the features not explained in this embodiment are explained in embodiment 1, and will not be repeated here to repeat. The difference between this embodiment and Embodiment 1 is that: the lifting swing rod 19 dislocation driving device is directly driven by the cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com