Oil varnish mitigation systems

一种油漆、油泵的技术,应用在燃气涡轮发动机领域,能够解决伺服机构损坏、收入损失、故障等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

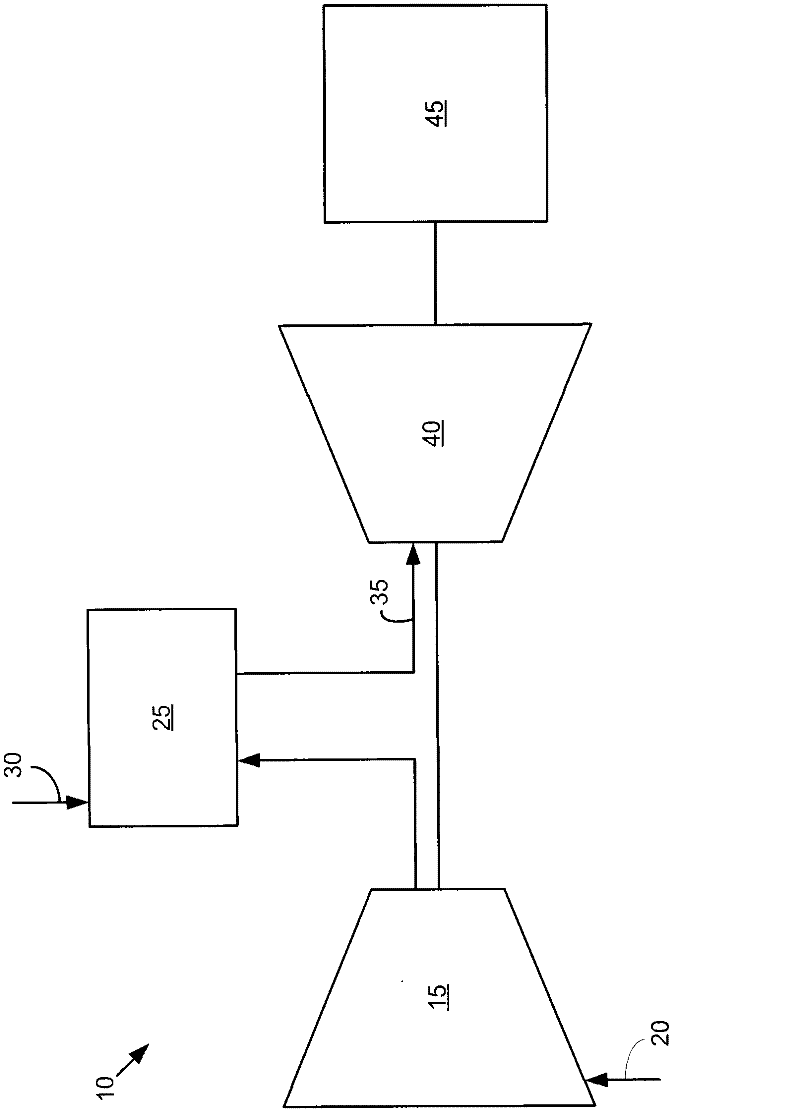

[0054] Referring now to the drawings, wherein like numerals represent like elements throughout the several views, FIG. 1 shows a simplified diagram of a known gas turbine engine 10 . Gas turbine engine 10 may include a compressor 15 . Compressor 15 compresses an incoming air stream 20 . Compressor 15 delivers compressed air stream 20 to combustor 25 . Combustor 25 mixes compressed air stream 20 with compressed fuel stream 30 and ignites the mixture to form combustion air stream 35 . Although only a single combustor 25 is shown, the gas turbine engine 10 may include any number of combustors 25 . Combustion gas flow 35 is then delivered to turbine 40 . Combustion gas flow 35 drives turbine 40 to produce mechanical work. The mechanical work produced in turbine 40 drives compressor 15 and an external load 45, such as a generator or the like.

[0055] Gas turbine engine 10 may use natural gas, various types of syngas, and / or other types of fuels. Gas turbine engine 10 may be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com