Multi-way reversing valve

A multi-way valve and channel technology, applied in the field of multi-way valves, can solve problems such as pressure rise, random stop devices, flow path switching action obstruction, etc., and achieve the effect of suppressing excessive pressure rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Next, embodiments of the four-way valve of the present invention will be described with reference to the drawings.

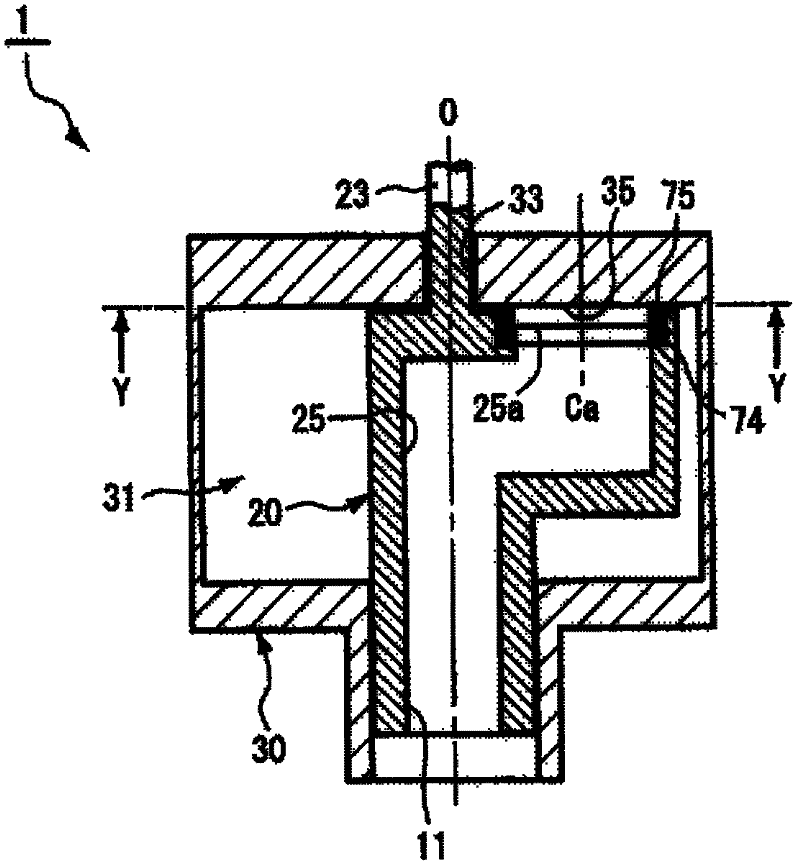

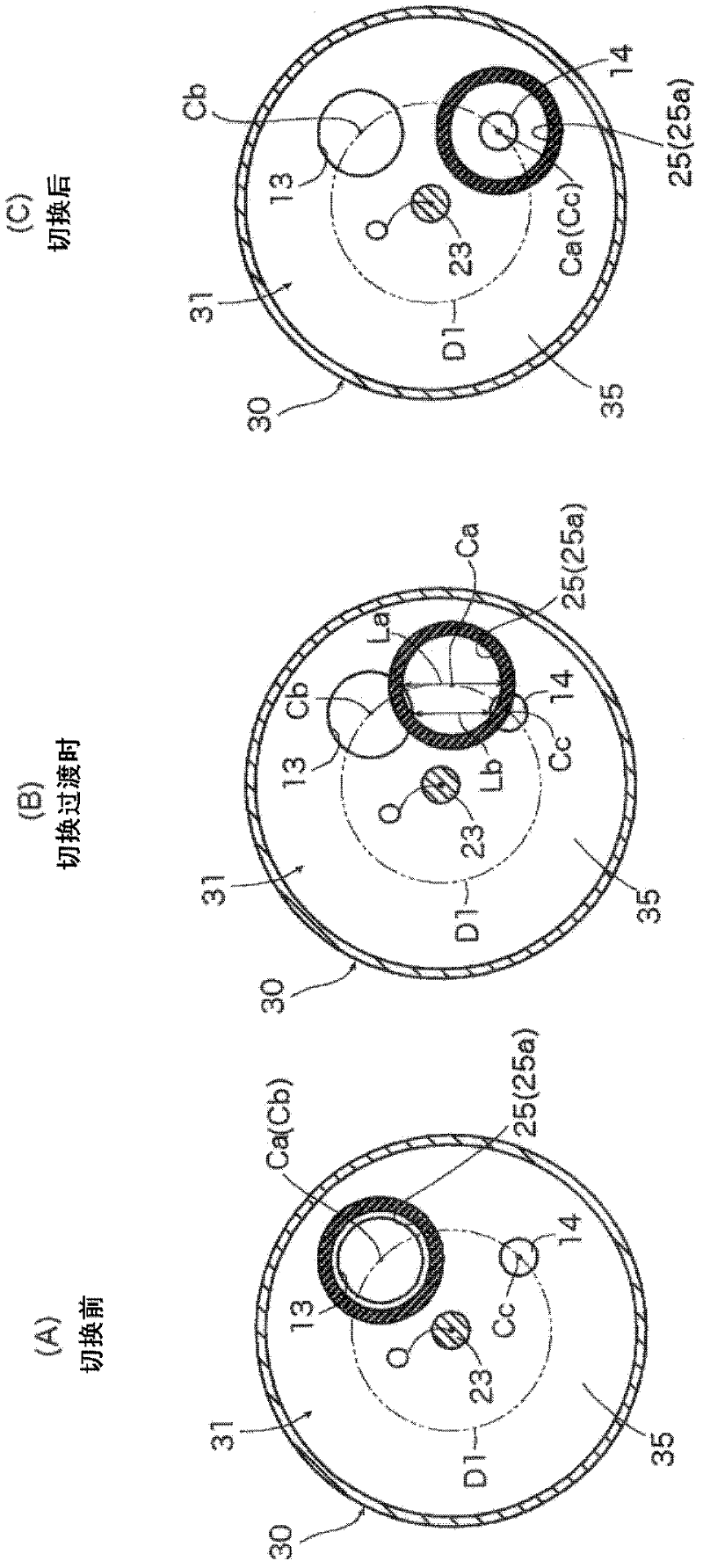

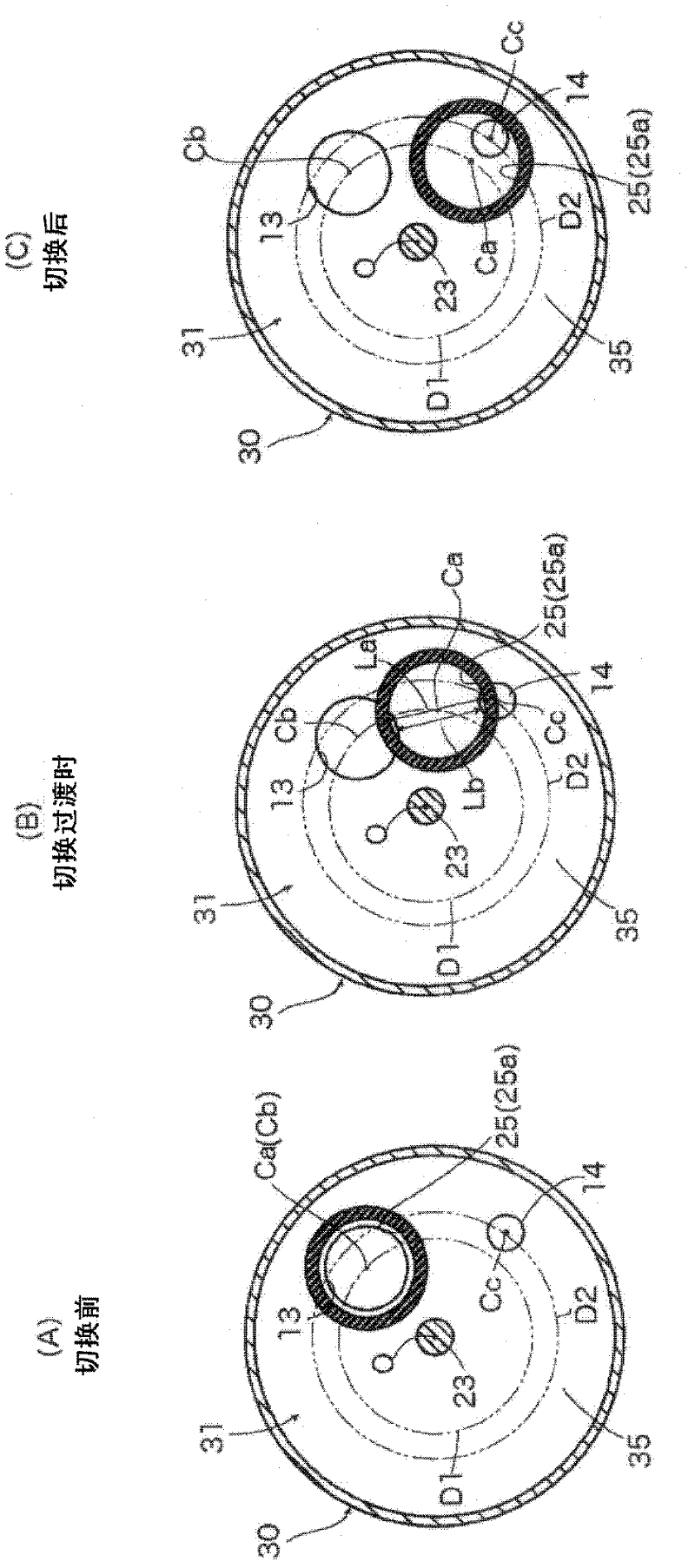

[0035] figure 1 It is a schematic cross-sectional view showing main parts of the first embodiment (the second and third embodiments are basically the same) of the multi-way valve (four-way valve) of the present invention, figure 2 From figure 1 The cross-sectional view viewed in the direction of the Y-Y arrow, image 3 , Figure 4 represent the equivalent of the second and third embodiments respectively figure 2 cross-sectional view. In addition, in the four-way valve 1 of the present embodiment, for the above-mentioned Figure 5 The parts corresponding to the respective parts of the shown conventional four-way valve 1' are denoted by the same symbols, and repeated explanations are omitted.

[0036] The first to third implementations of the present invention are applicable to the above-mentioned Figure 5 In the electric valve, the electric valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com