Intelligent robot fire extinguishing system and intelligent robot fire extinguishing method

An intelligent robot and fire extinguishing system technology, applied in fire rescue and other fields, can solve the problems of uneven fire extinguishing effect, fire extinguishing, and lack of automatic patrol inspection, etc., and achieve the effect of improving intelligence and fire extinguishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

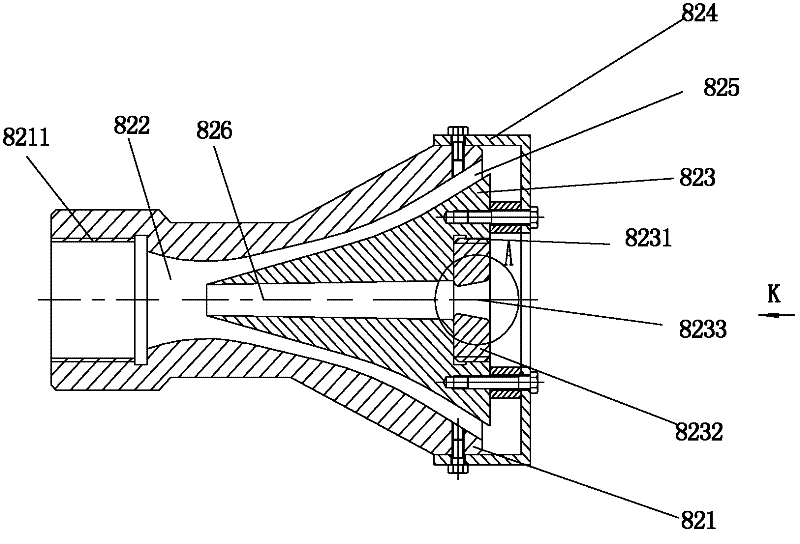

[0046] refer to Figure 2a to Figure 2c , Embodiment one of the nozzle of the present invention is as follows:

[0047] The nozzle 82 includes a nozzle body 821 connected to the pipe network. A nozzle flow channel 822 is provided inside the nozzle body. The nozzle flow channel 822 is used for the passage of high-speed dry powder air flow. A riser 823 is nested in the nozzle flow channel 822. In this embodiment, a single core is used as the riser in this embodiment. The taper of the riser 3 is 60°. The riser 823 is fixedly connected to the nozzle body 821 through a fixing frame 824. The fixing frame Such as Figure 2b As shown, it is a connecting piece with multiple connecting claws. The riser 823 is fixed to the connecting piece by screws, and the connecting piece is fixed on the nozzle body 821 through the connecting claws to realize the fixing of the riser 823 and the nozzle body 821. There is no contact connection between the rear nozzle body 821 and the riser 823, and th...

Embodiment approach 2

[0050] refer to Figure 2d As shown, the embodiment two of the nozzle of the present invention is as follows:

[0051] It includes a nozzle body 821 connected to the pipe network. A nozzle flow channel 822 is provided inside the nozzle body. The nozzle flow channel 822 is used for the passage of high-speed dry powder airflow. A riser 823 is nested in the nozzle flow channel 822. This implementation The riser 823 mentioned in the method is a composite core, and the composite core is composed of a 60° conical composite core 827 and a 30° conical composite core 828, and the 60° conical composite core 827 is directly nested in the nozzle In the flow channel 821, the 30° conical composite core 828 is nested in the 60° conical composite core 827, and the composite core is fixedly connected to the nozzle body 821 through the fixing frame 824, so as to realize the alignment of the riser 823 Fixing with the nozzle body 821, after fixing, there is no contact connection between the nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com