Image recording apparatus

A technology for image recording and recording media, applied in printing devices, typewriters, printing, etc., can solve problems such as poor image registration and processing defects, achieve uniform water content, and reduce shrinkage changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, embodiments related to the present invention will be described with reference to the drawings.

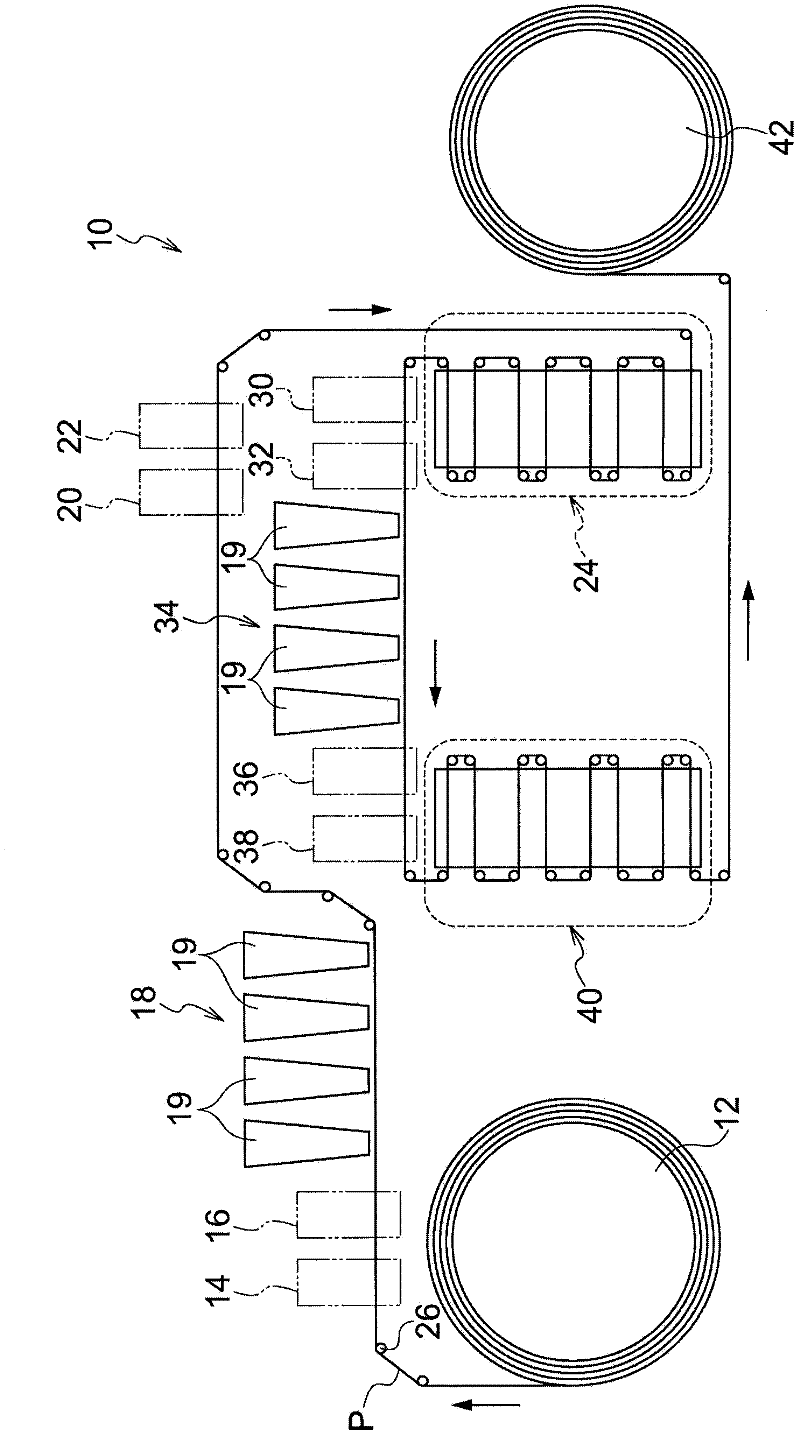

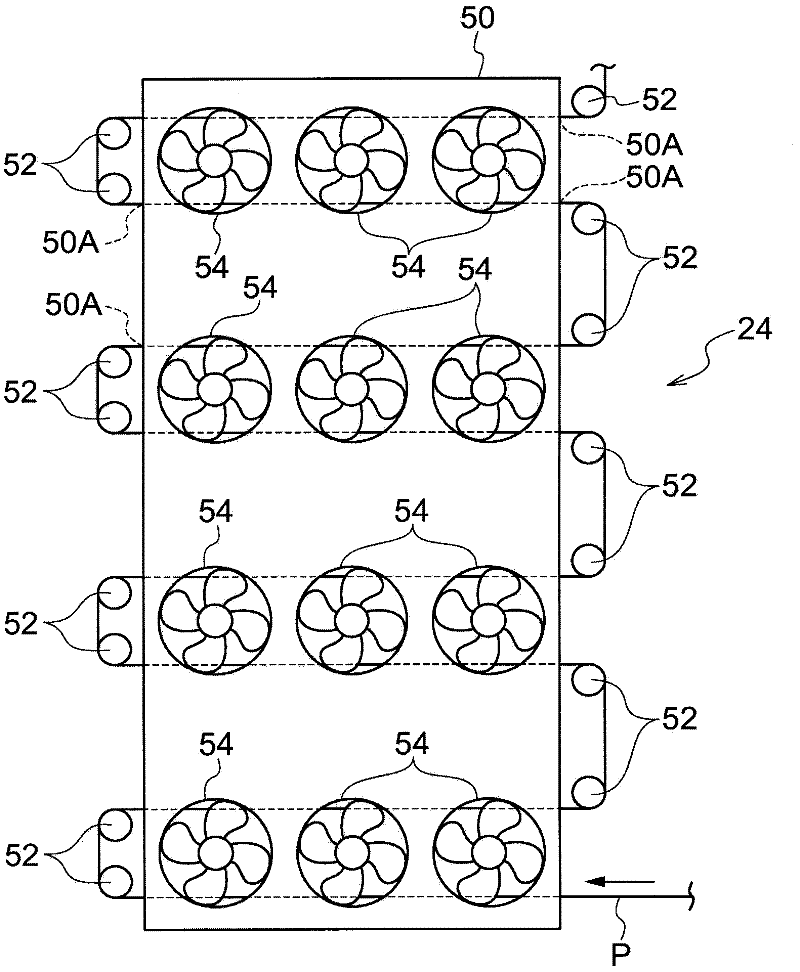

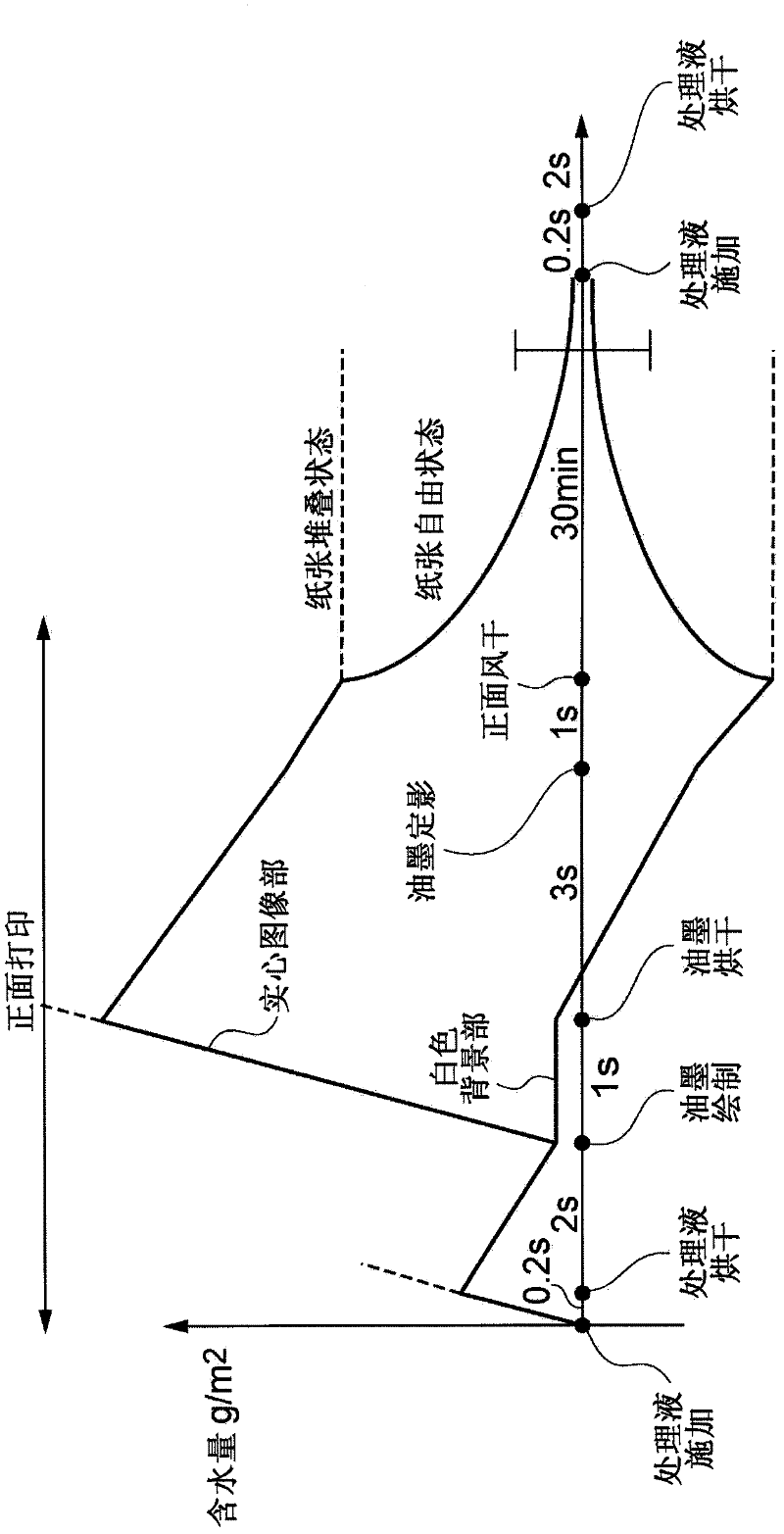

[0034] Such as figure 1 As shown, the continuous printing device 10 serving as an example of the image recording device related to the present embodiment is a duplex printing device that conveys a roll paper (continuous paper) P serving as a continuous recording medium, and Images are formed on the front and back sides of the roll paper P. As shown in FIG. In the continuous printing apparatus 10 , on the upstream side in the conveying direction of the rolled paper P, a feed roller 12 serving as a conveying unit that feeds and conveys the rolled paper P is provided.

[0035]The rolled paper P pulled out from the feed roller 12 is conveyed in one direction while being wound around a plurality of rollers 26 . Each processing section of the continuous printing apparatus 10 related to the present embodiment is schematically shown in the figure for easy understandin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com