Belt monitoring system for carrying device

A technology for monitoring systems and handling equipment, which is applied in transportation and packaging, conveyor control devices, conveyor objects, etc., and can solve the problems of suspended equipment with or without load that cannot be prevented in advance, maintenance increases, and early warning cannot be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the description of the present invention more detailed and complete, reference may be made to the attached drawings and various embodiments described below, and the same numbers in the drawings represent the same or similar elements. However, the provided embodiments are not intended to limit the scope of the present invention, and the description of the structure and operation is not intended to limit the order of its execution. Any device recombined by components to produce devices with equivalent functions is the subject of this invention. scope covered by the invention. The drawings are for illustration purposes only and are not drawn to original scale. On the other hand, well-known elements and steps have not been described in the embodiments in order to avoid unnecessarily limiting the invention.

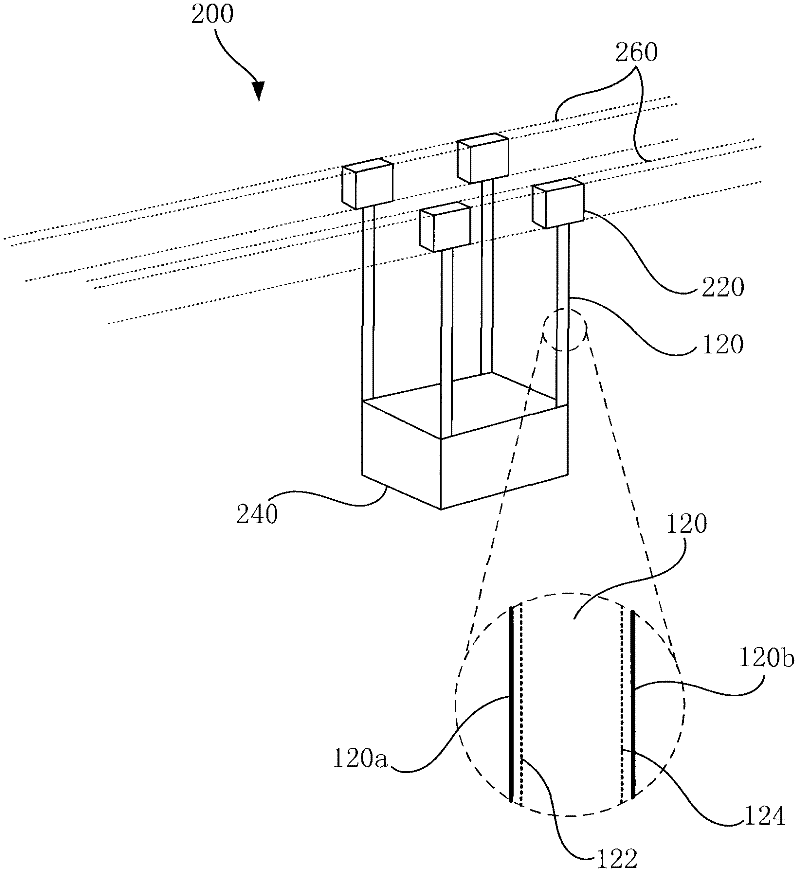

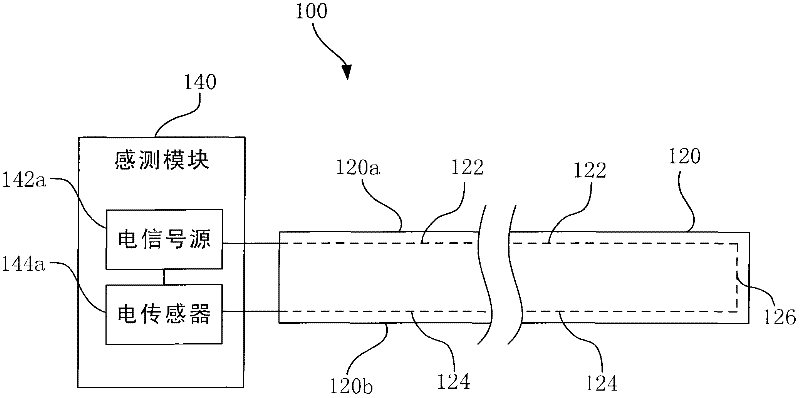

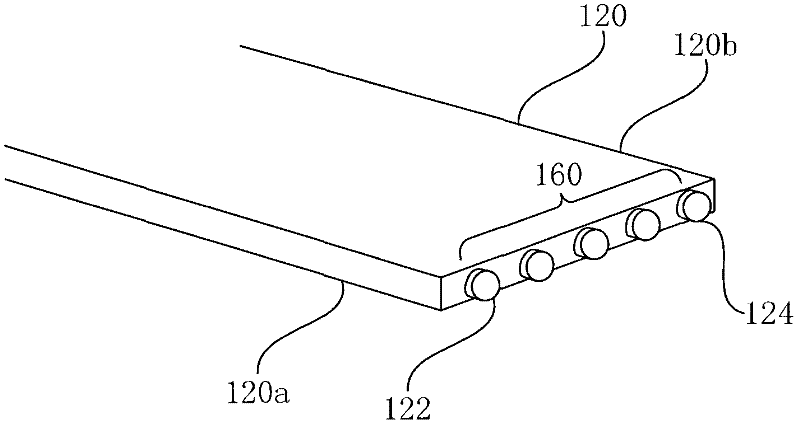

[0033] see figure 1 and figure 2 , figure 1 A schematic diagram of a transporting device 200 according to an embodiment of the present invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com