Positive feeder unit for feeding wire at constant tension

A metal wire, tension sensor technology, used in the transportation of filamentous materials, transportation and packaging, inductance/transformer/magnet manufacturing, etc., can solve problems such as no description

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

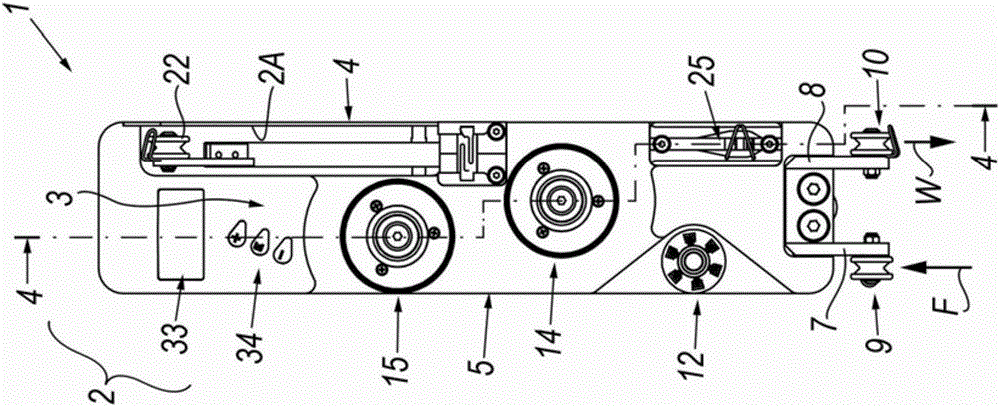

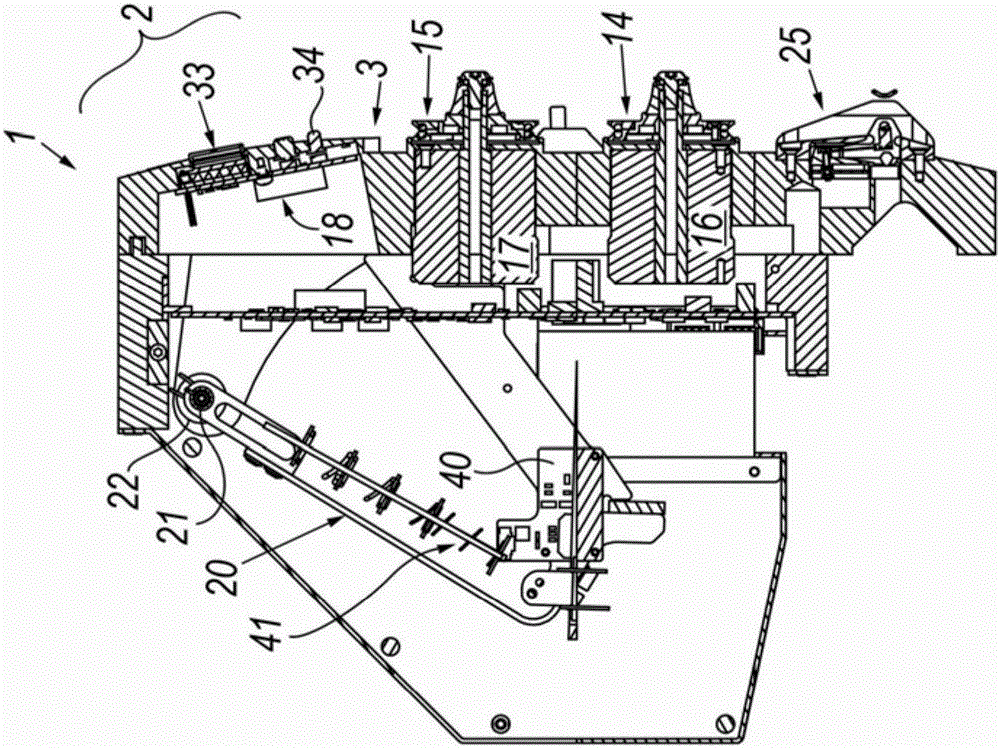

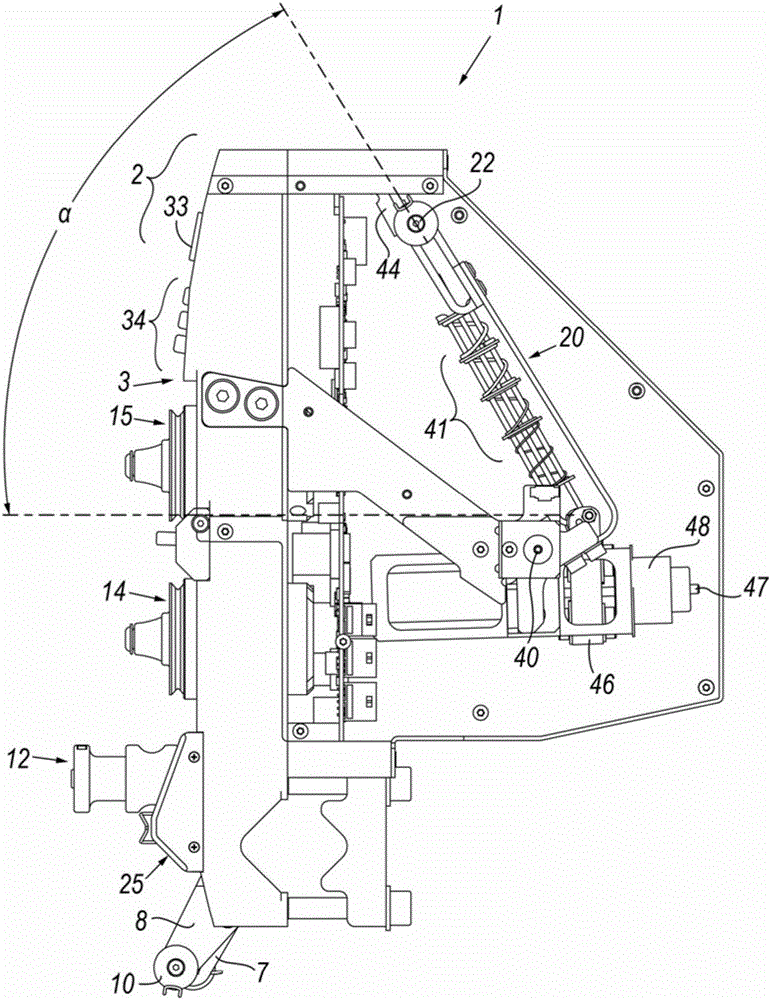

[0036]Referring to said figures, the wire feeder device is generally indicated at 1 and comprises a main body or housing 2 comprising a front 3 and sides 4 and 5 . The sides 4 and 5 are closed by cover elements which are not in the figure 2 with 3 shown in .

[0037] There are parallel supports 7 and 8 on, or associated with and protruding from, the front face 3 (cf. figure 1 Starting from the bottom of the main body 2 ), the supports 7 and 8 support corresponding grooved rollers 9 or 10 which rotate freely on pins fixed to the respective supports. The purpose of the rollers 9, 10, preferably made of ceramics, is to define the trajectories of the wire from the spool (not shown) to the device 1 and from the device 1 to the processing machine (also not shown), these trajectories are indicated by F and W respectively . The fact that the rollers are made of ceramic (or an equivalent low coefficient of friction material) minimizes the friction between the wire and the roller, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com