Production method of polyphthalamide (PPA) long-fiber-coated reinforced material

A technology of polyphthalamide and reinforcing materials, which is applied in the field of preparation of high-strength and high-temperature-resistant PPA reinforcing materials, can solve the problems of limited application fields, insufficient strength and stiffness to completely replace, and achieve good application prospects, long-term value-in-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

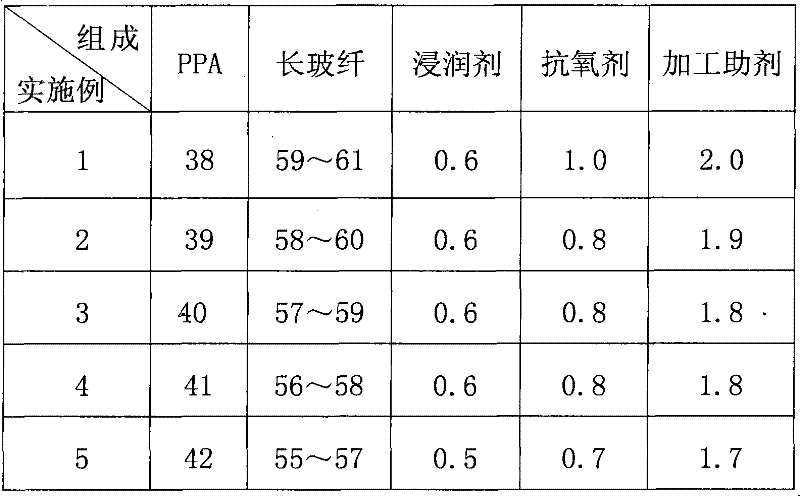

Embodiment 1

[0018] Weigh the plate by weight parts crystalline polyphthalamide: 38 parts, wetting agent KH550: 0.6 parts, antioxidant 1098 and 626 according to 1:2 compound: 1.0 parts, processing aid PETS: 2.0 parts share.

[0019] Composite materials were prepared as follows:

[0020] a. The raw material polyphthalamide is dehumidified and dried (dew point -40°C, drying temperature 130°C, time 6 hours);

[0021] b. Weigh the dried polyphthalamide into the high-temperature machine, add the corresponding wetting agent, antioxidant, and processing aid at the same time, and mix at high speed for 5 minutes;

[0022] c. Add the high-mixed raw and auxiliary materials into the twin-screw feeding port of the long fiber coating machine for melt extrusion, that is, plasticization; then add the long glass fiber that has passed through a 15m long drying tunnel and dried at 122°C into the long fiber The die head of the coating machine is infiltrated and coated. The glass fiber content is adjusted by...

Embodiment 2

[0027] Weigh semi-crystalline polyphthalamide in parts by weight: 39 parts, wetting agent 570: 0.6 parts, antioxidant 1098 and 626 according to 1:1 compound: 0.8 parts, processing aid silicone master Granules MB50-11: 1.9 parts. Composite materials were prepared according to the following steps:

[0028] a. Dehumidify and dry the raw material polyphthalamide (dew point -40°C, drying temperature 130°C, time 5.5 hours);

[0029] b. Weigh the dried polyphthalamide into the high-mixer, add the corresponding wetting agent, antioxidant and processing aid at the same time, and mix it for 5 minutes;

[0030] c. Add the high-mixed raw and auxiliary materials into the twin-screw feeding port of the long fiber coating machine, and carry out melt extrusion, and then add the long glass fiber dried at 125 °C through a 15m long drying tunnel into the long glass fiber bag The die head of the coating machine is soaked and coated, and the long glass fiber content is adjusted by the pulling sp...

Embodiment 3

[0035] Weigh semi-crystalline polyphthalamide in parts by weight: 40 parts, wetting agent KH550: 0.6 parts, antioxidant 1098 and 626 according to 1:0.4 compound: 0.8 parts, processing aids PETS and silicon 1:1 compound of ketone masterbatch MB50-11: 1.8 parts.

[0036] Composite materials were prepared according to the following steps:

[0037] a. Dehumidify and dry the raw material polyphthalamide (dew point -40°C, drying temperature 140°C, time 5 hours);

[0038] b. Weigh the dried polyphthalamide into the high-mixer, and add the corresponding wetting agent, antioxidant and processing aid at the same time, and then high-mix for 4 minutes;

[0039] c. Put the high-mixed raw and auxiliary materials into the twin-screw feeding port of the long fiber coating machine, carry out melt extrusion, and then add the long glass fiber dried at 130°C through a 15m long drying tunnel into the long glass fiber coating machine. The die head is soaked and coated, and the long glass fiber co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com