Reinforced concrete overlapped floor slab

A reinforced concrete and laminated floor technology, which is applied to floors, building components, buildings, etc., can solve the problems of unevenness at the bottom of the floor, unevenness of the floor, and limited rigidity against deformation, so as to achieve good engineering quality and reduce poor deformation , the effect of low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

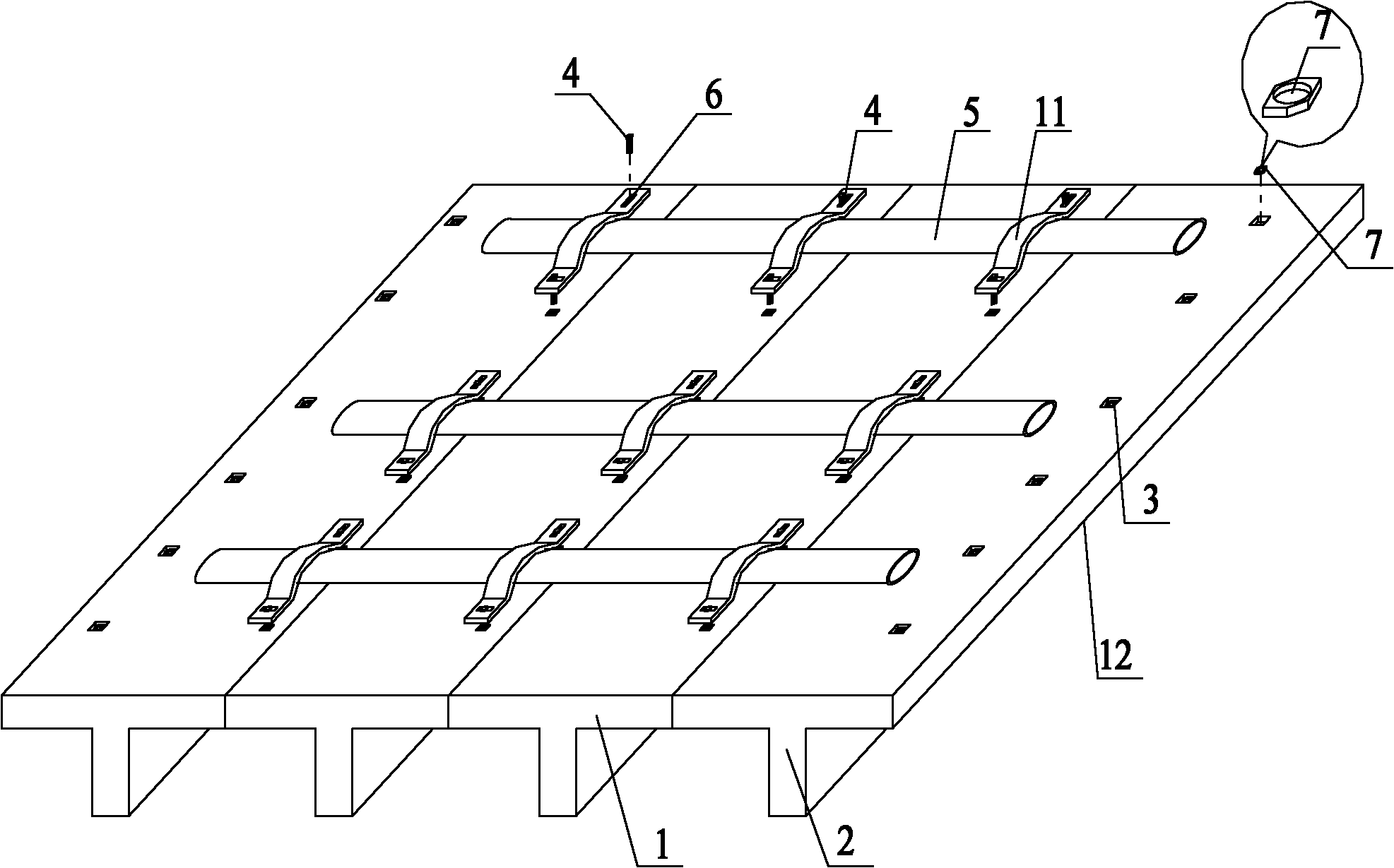

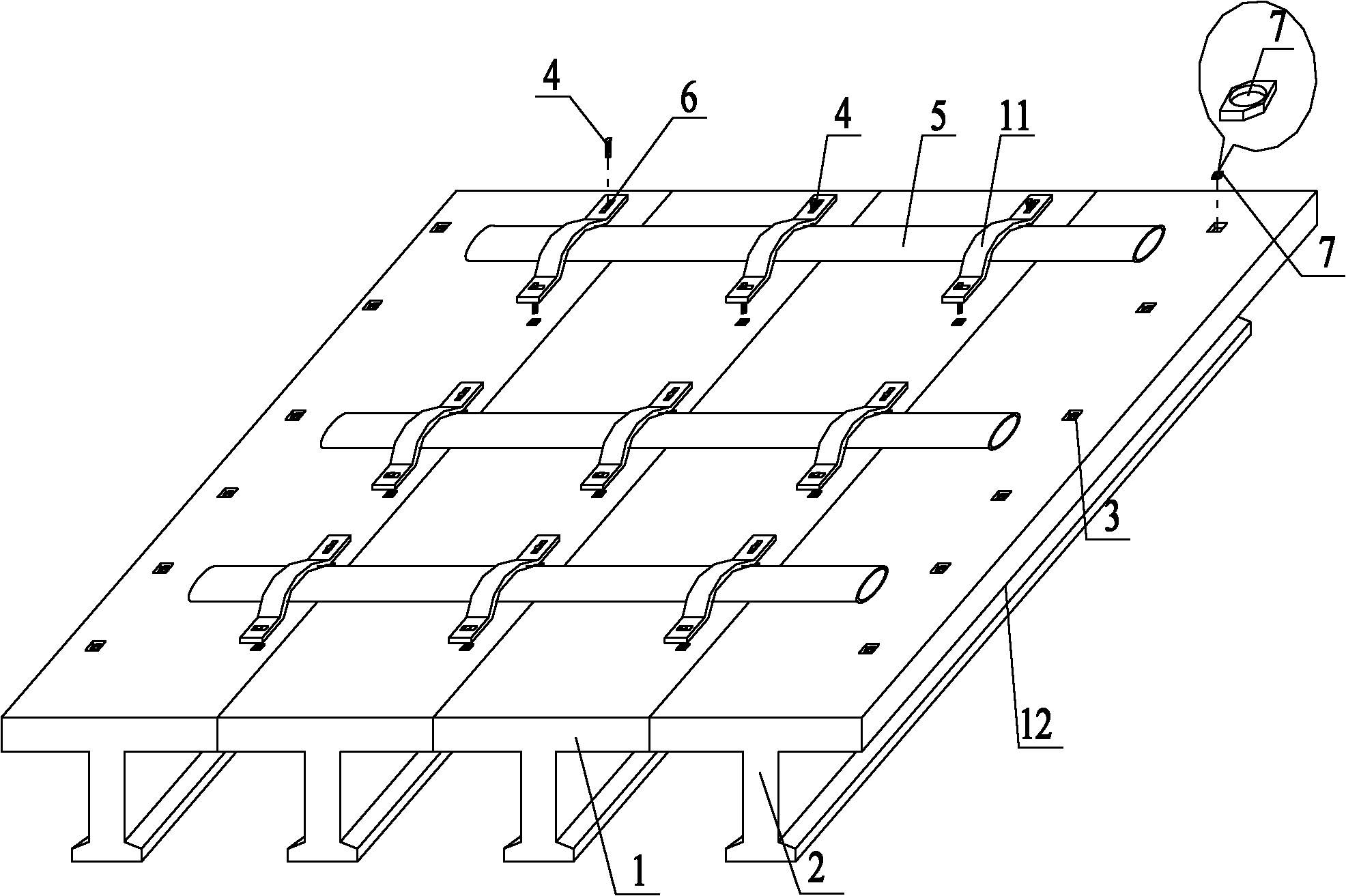

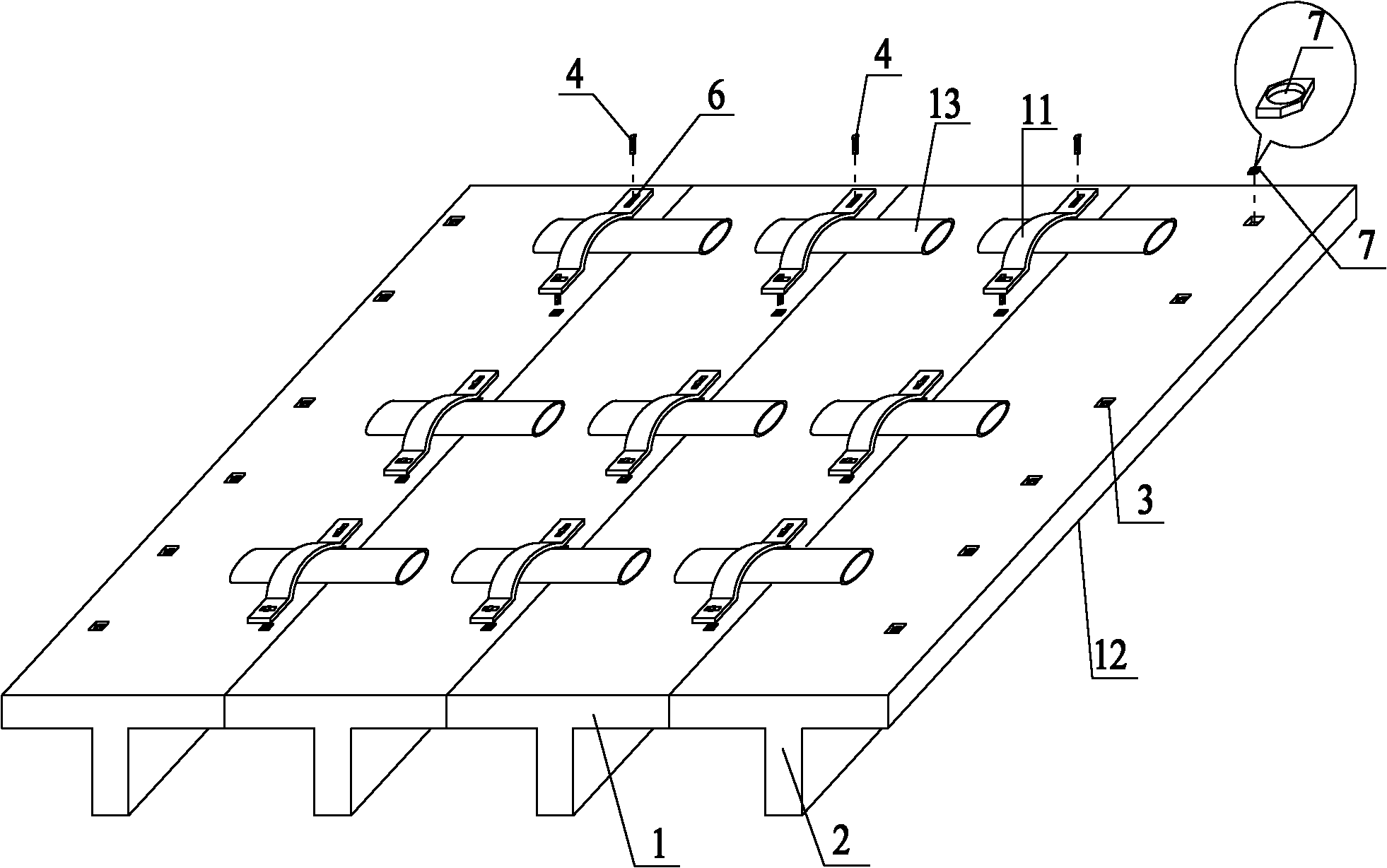

[0030] The present invention will be further described below in conjunction with accompanying drawing.

[0031] The invention is attached Figure 1-20 As shown, a reinforced concrete laminated floor slab includes a prefabricated ribbed member slab 12, transverse steel bars 9, and a concrete laminated layer 10. The prefabricated ribbed member slab 12 includes a reinforced concrete bottom slab 1 and a longitudinal rib 2 on which the There are transverse through holes 8 . The present invention is characterized in that there are holes or grooves 3 at the bottom of the reinforced concrete bottom plate 1, and nuts 7 are pre-embedded in the holes or grooves 3, and the nuts 7 are connected with the bolts 4 on the pressure plate 11, and between the pressure plate 11 and the bottom plate 1 Fix the long and long connecting rod 5 or the short rod 13. figure 1 It is a schematic diagram of connecting the rectangular rib prefabricated component plate 12 with the pressing plate 11 and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com