Spiral-flow type extraction and exhaust device with split structure

An exhaust device and split structure technology, which is applied in the field of swirling exhaust and exhaust devices, can solve problems such as difficult cleaning, reduced fan performance, and increased noise, and achieves the effects of easy cleaning, compact structure, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

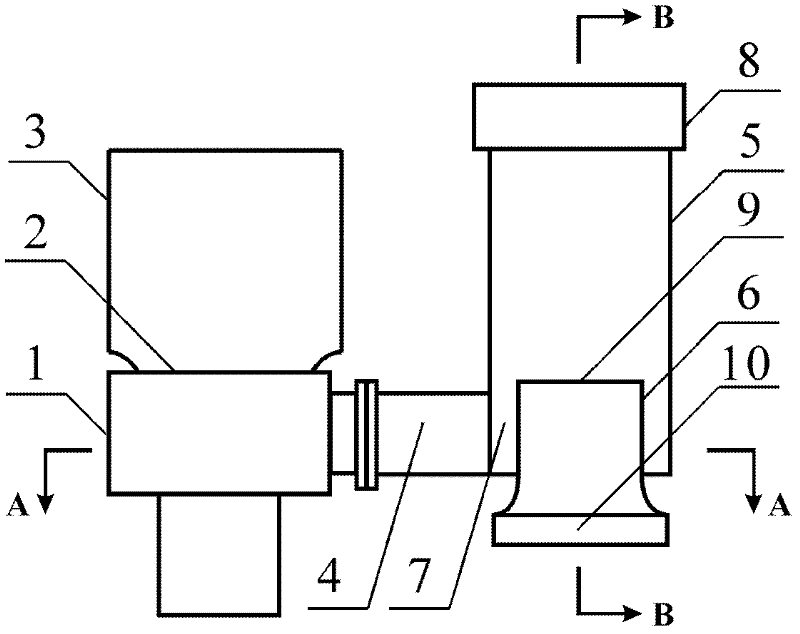

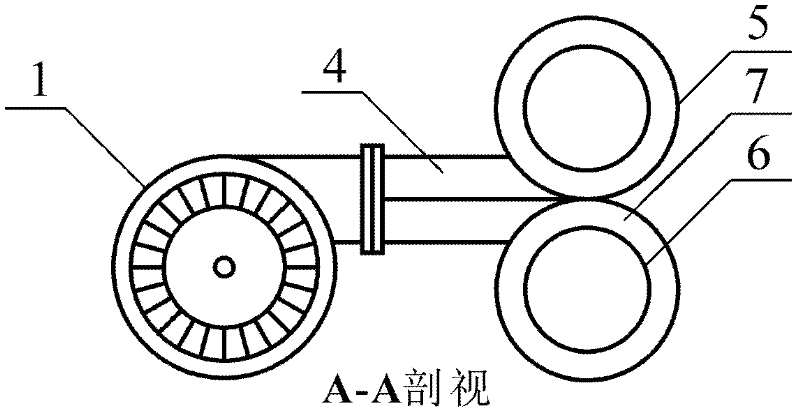

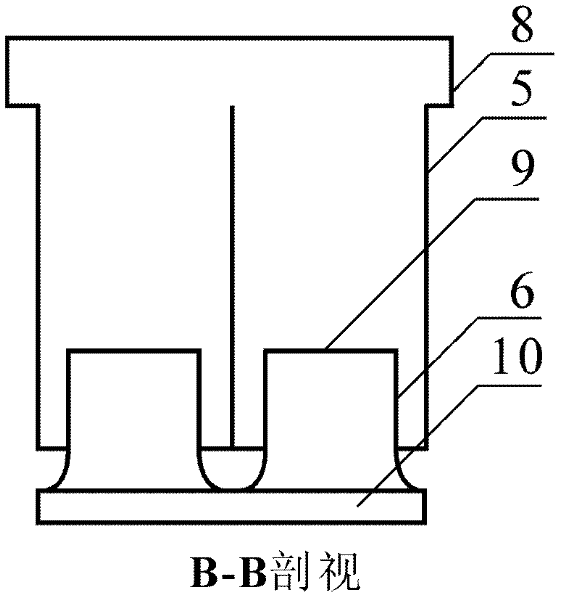

[0028] This embodiment is an implementation of a swirling air exhaust device with a split structure. figure 1 is a schematic diagram of its longitudinal section structure, figure 2 yes figure 1 The A-A cross-sectional structure schematic diagram of image 3 yes figure 1 Schematic diagram of the B-B cross-sectional structure.

[0029] Such as figure 1 , figure 2 and image 3As shown: In this embodiment, the air inlet 2 of the centrifugal fan 1 is connected with the air inlet pipe 3; there are two sets of swirl entrainment sleeves matching the fan 1, with the same shape and arranged side by side; the swirl entrainment sleeves The inner cylinder 6 with the central axis extends into the outer cylinder 5 to form an annular swirl groove 7 sealed at the bottom of the groove. The inner cylinder 6 and the outer cylinder 5 are straight-through circular pipes; The air supply duct 4 of the fan 1 is installed in a hole; the air supply duct 4 of the fan 1 is divided into two parts ...

Embodiment 2

[0033] This embodiment is another implementation of the swirling air exhaust device with split structure. figure 1 is a schematic diagram of its longitudinal section structure, Figure 4 yes figure 1 A-A cross-sectional schematic diagram of the structure.

[0034] Such as figure 1 and Figure 4 Shown: In this embodiment, only one set of swirl entrainment sleeves is used, and its structure is the same as that of Embodiment 1, the difference is that the air supply duct 4 of the fan 1 does not need to be divided again, and the centrifugal fan 1 is the same as that of the embodiment When 1 is the same, the geometric size of the swirl entrainment sleeve is 1.3 times larger than that of the single swirl entrainment sleeve in Example 1. When in use, start the centrifugal fan 1, draw clean air from the air inlet pipe 3 of the fan 1, and transport it to the annular swirl groove 7 of the swirl entrainment sleeve through the air supply pipe 4 of the fan 1, and the high-speed rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com