Clamping block of lead clamping device

A technology of wire clamps and clamping blocks, which is applied in the installation of cable installation devices, electrical components, cables, etc., can solve the problems of wire clamps slipping, wire clamps falling off, and wire clamps slipping, etc., so as to reduce wire damage , the effect of increasing the friction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

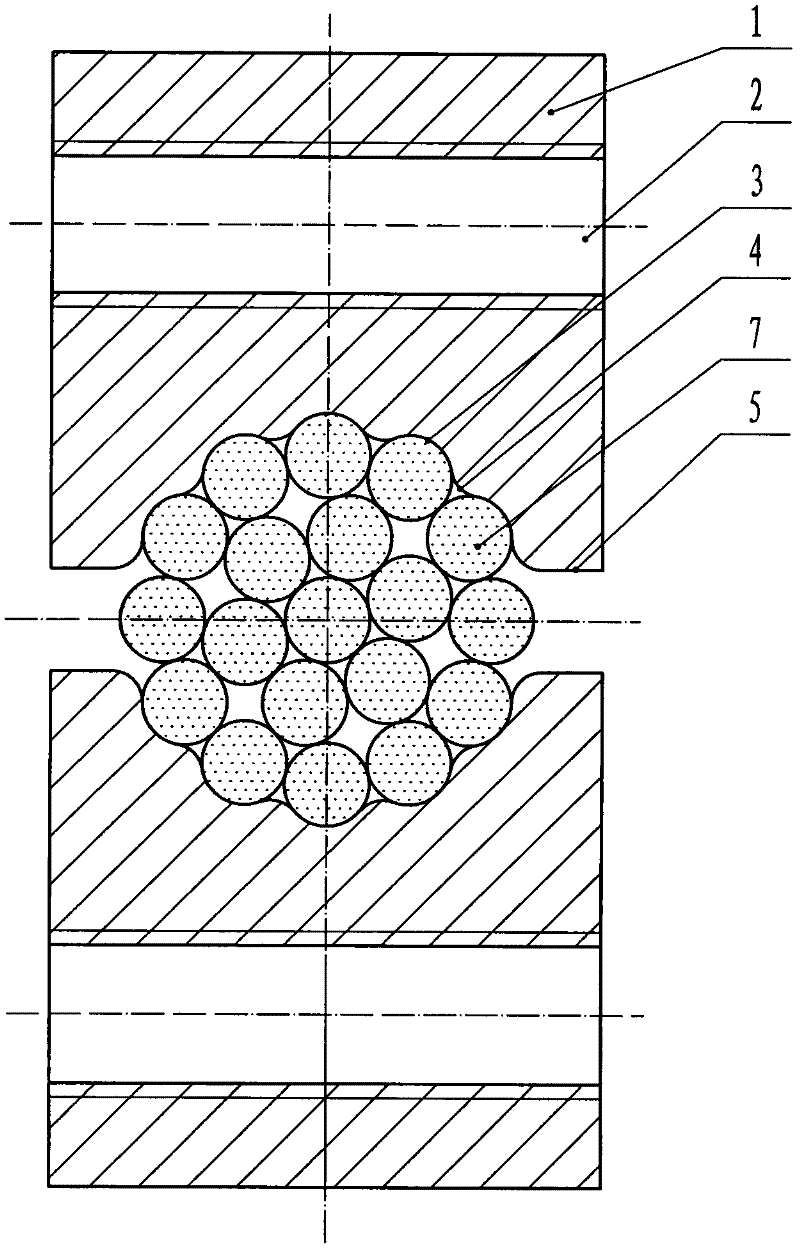

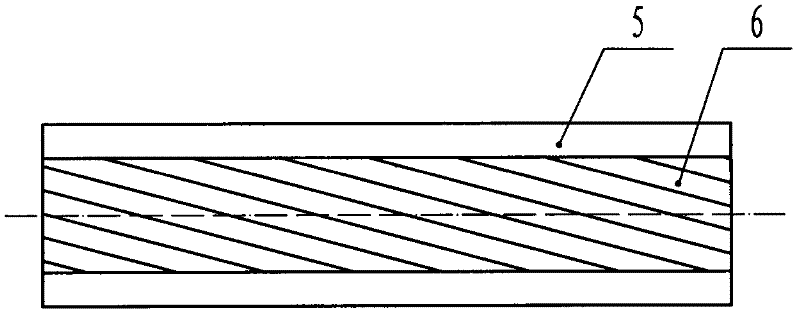

[0014] Such as Figure 1 ~ Figure 4 As shown, when the wire clamp block of the present invention is used, two pieces are arranged symmetrically. The two pieces have the same structure. A wire clamping slot 6 is provided, and the shape of each wire clamping block body 1 is an approximate cuboid.

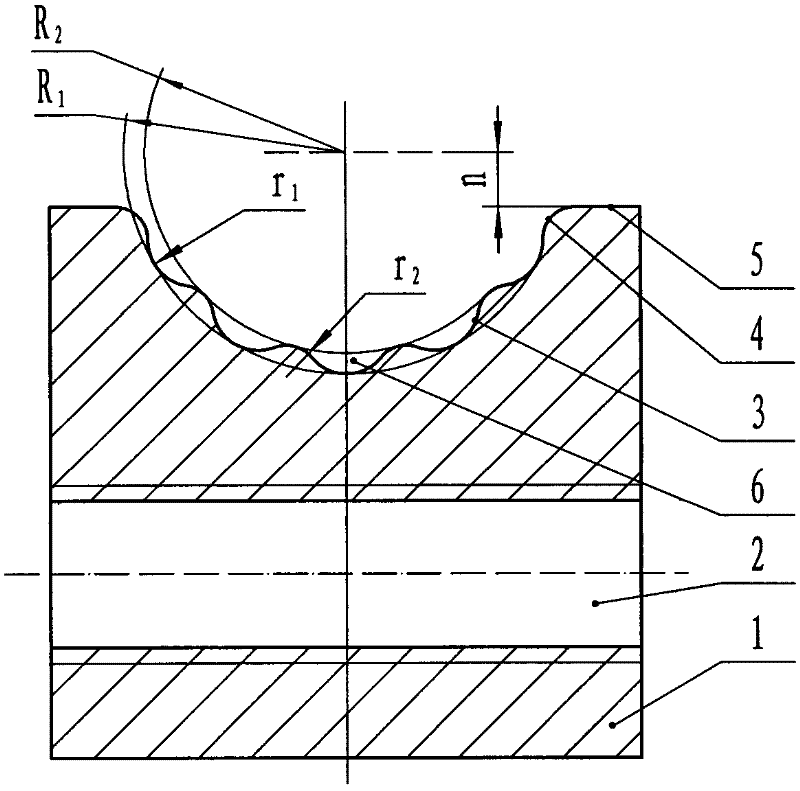

[0015] Such as figure 2 As shown, the section of the clamping slot 6 is a radius r 1 The curved surface 3 of the single-strand aluminum wire that is equal to the radius of the outer ring of the wire 7 and the radius is r 2 Composed of the transition arc surface 4, the arc vertices of the card line arc surface 3 and the intermediate transition arc surface 4 are respectively distributed in the radius R 1 and half warp R 2 On the arc of the arc, the card line arc surface 3 and the transition arc surface 4 are tangent to form a wavy trough arc surface, R 1 Equal to the radius of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com