Washing structure of dish washer

A technology for dishwashers and cups, which is applied to tableware washing machines/rinsing machines, tableware washing machines/rinsing and rinsing machine parts, cleaning equipment, etc., which can solve problems such as unfavorable tableware cleaning, achieve strong washing, and solve difficult washing Tableware, the effect of improving the cleaning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

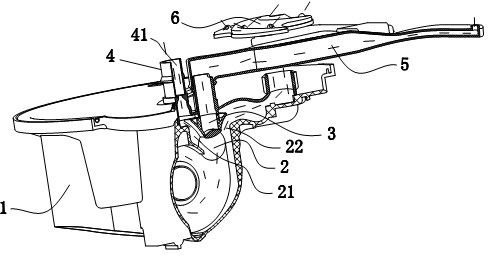

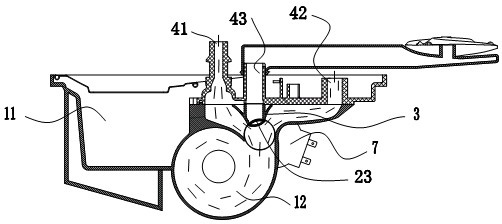

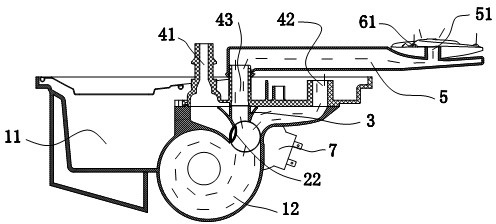

[0022] Such as Figures 1 to 9 As shown, a washing structure of a dishwasher is characterized in that it includes a water cup 1, a paddle 2, a diverter 3, a spray arm seat 4, an inner water pipe 5, a nozzle 6 and a motor 7; wherein the motor 7 is installed On the outer wall of the water cup 1; the spray arm seat 4 is installed on the water cup 1, and the spray arm seat 4 is provided with a first water outlet channel 41, a second water outlet channel 42 and a third water outlet channel 43 isolated from each other; The part 3 is installed in the groove of the water cup 1 and pressed down on the water cup 1 by the spray arm seat 4, and the diverter part 3 cooperates with the inner wall of the water cup 1 to form a first water inlet 21, a second water inlet 22 and a third water inlet which are isolated from each other. The water inlet 23, the first water inlet 21 communicates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com