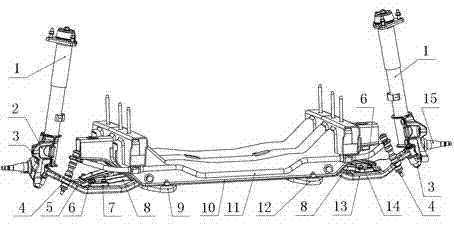

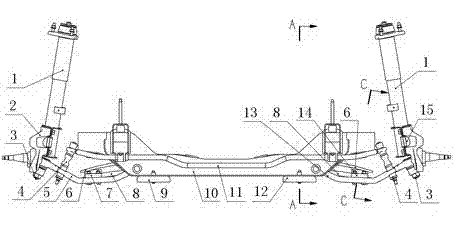

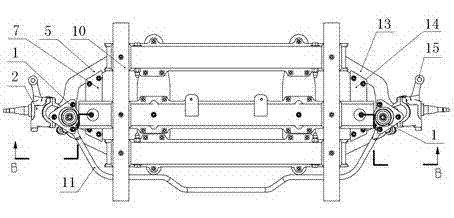

Transversal leaf spring type front independent suspension mechanism with sliding blocks at two ends

A technology of independent suspension and leaf spring, which is applied in the direction of suspension, elastic suspension, transportation and packaging, etc., can solve the problems of not being able to meet the carrying capacity and ride comfort of commercial vehicles at the same time, poor no-load ride comfort, and weakened carrying capacity, etc. Achieve the effects of compact structure, reduced tilt and vibration, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Both the upper leaf spring 6 and the lower leaf spring 8 are variable-section leaf springs. According to the principle of stress and strain, when the rigidity requirements of the vehicle are met, the cross-sections at both ends of the leaf spring gradually become smaller from the inside to the outside of the fixing point. Put the two lower pads 20 on the left leaf spring fixed plate 9 and the right leaf spring fixed plate 12 respectively, put the lower leaf spring 8 on the two lower pads 20, and place the two inter-plate pads 19 is placed on the lower leaf spring 8, through the center hole of each piece, use two center bolts and two nuts to connect the spacer 19 between the plates, the lower leaf spring 8, the spacer 20 under the plate, and the left leaf spring fixing plate 9 and The right leaf spring fixing plate 12 is fixed together.

[0039] Put the two upper backing plates 18 on the upper leaf spring 6 respectively, align the center hole with the left and right cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com