Floater system connected with floating production storage and offloading (FPSO) boat body

A sub-system and buoy technology, applied in the field of buoy systems, can solve problems such as not being able to adapt to the natural environment of the South China Sea, limit the number and form of risers, and be expensive, and achieve convenient and fast connection and release, simple and efficient lifting devices, and fast positioning and anti-rotation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

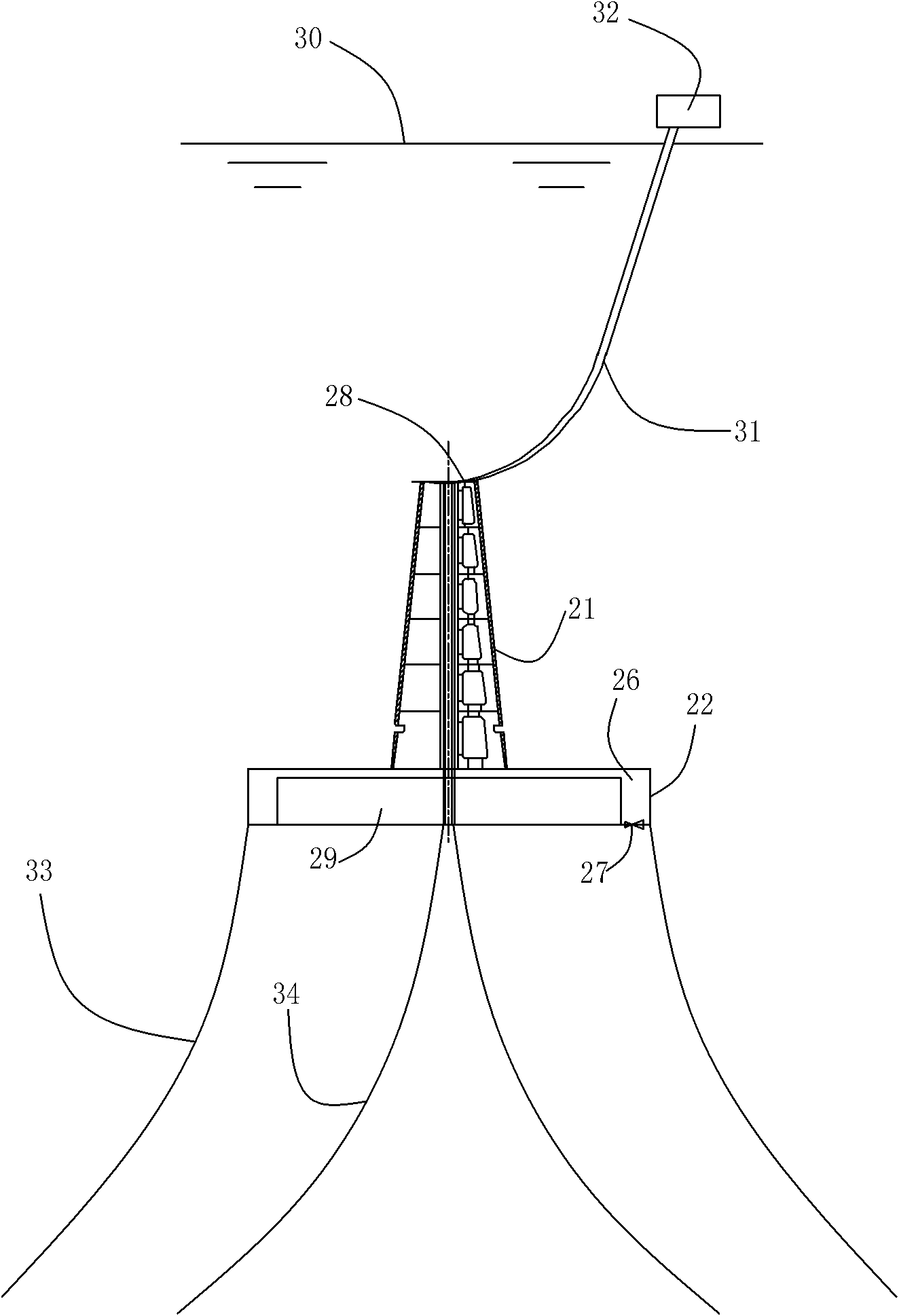

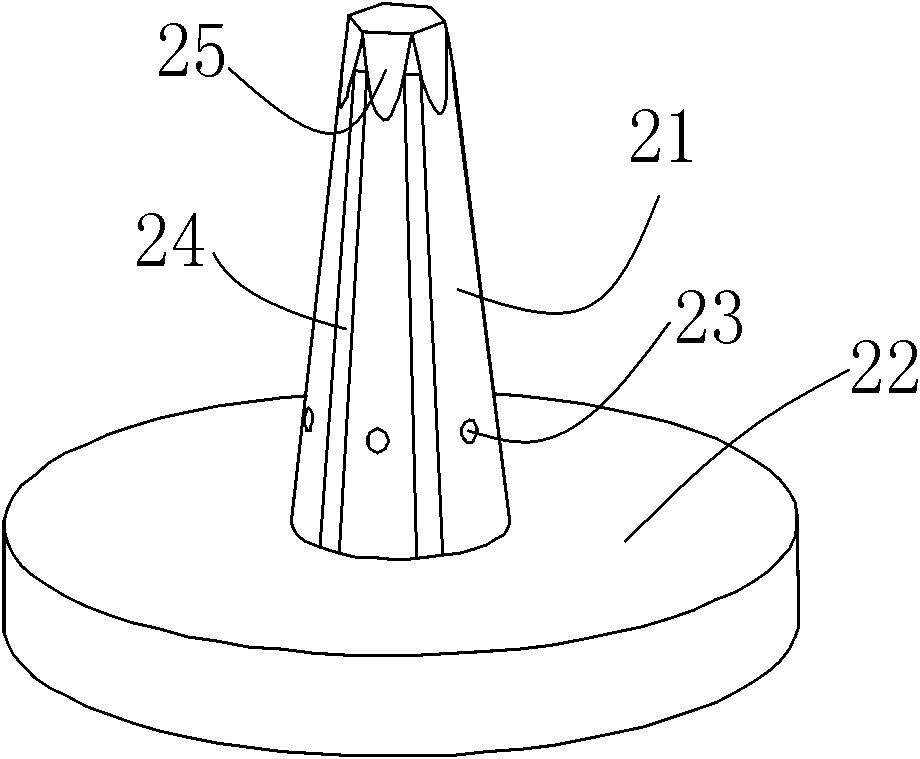

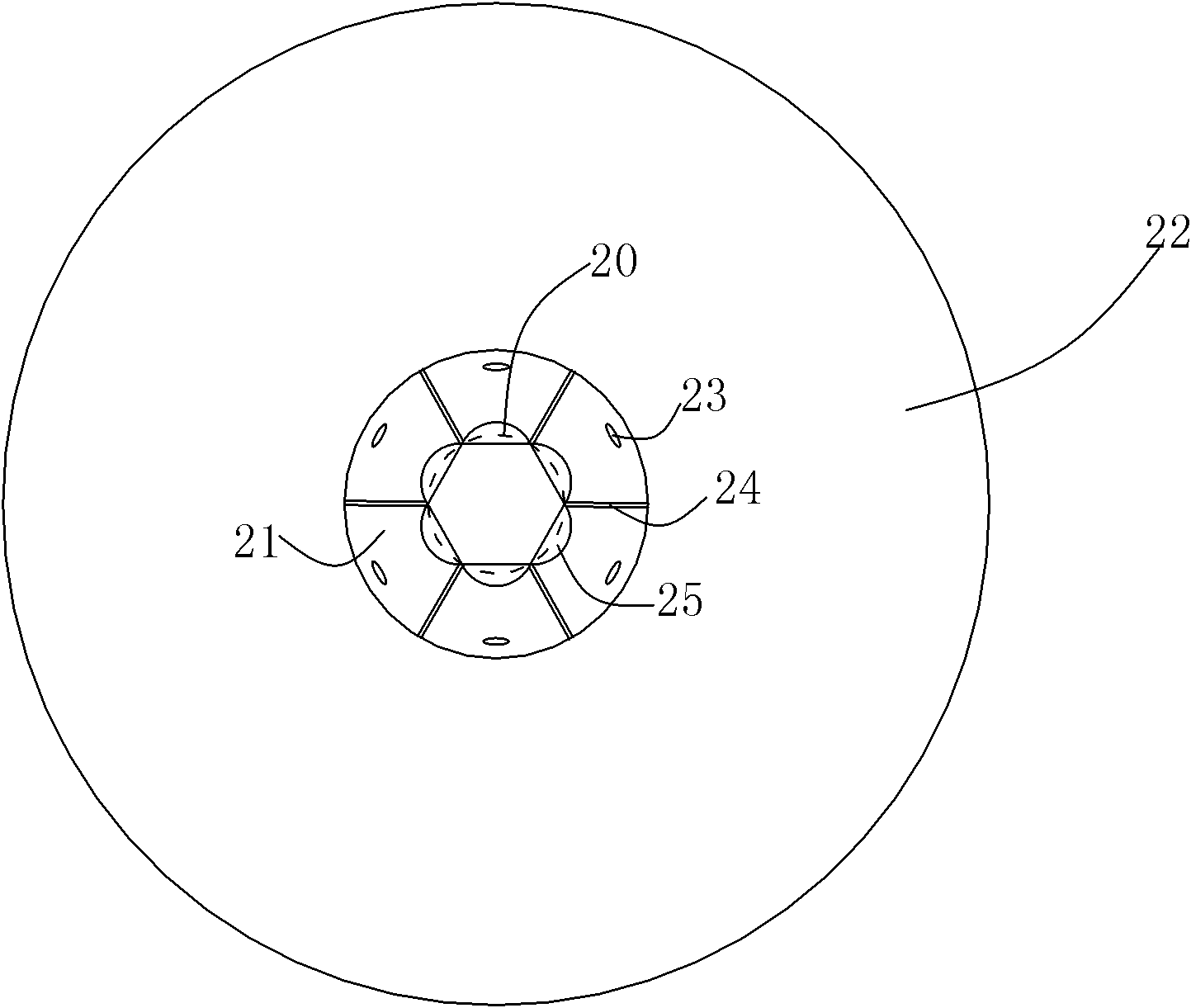

[0024] Such as figure 1 As shown, a kind of buoy system for being connected with FPSO hull of the present invention comprises buoyant and anchor chain 33 that is connected with buoyant, riser 34 etc., and wherein buoyant comprises a cone part 21 and a base 22, and cone part 21 The bottom surface of the bottom is fixed on the base 22. The base 22 is provided with a permanent floating chamber 29 and a drainage chamber 26, the permanent floating chamber 29 is an airtight cavity, the drainage chamber 26 is arranged on the periphery of the permanent floating chamber 29, and the inner cavity of the cone part 21 communicates with the base, Together they constitute the drainage compartment 26 . The bottom of the drainage compartment 26 is provided with a drain opening 27 that can be opened and closed, and the top of the cone portion 21 is provided with a vent 28 that communicates with the drainage compartment 26. A compressor 32 is connected, and the air compressor 32 is typically l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com