Blanking machine for gum production and capable of preventing material blockage and using method of blanking machine

A blanking machine and adhesive technology, which is applied in the field of blanking machines for adhesive production, can solve problems affecting the feeding efficiency of adhesive raw materials and blockage of the discharge pipe, so as to improve practicability, avoid waste of raw materials, and increase flow rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

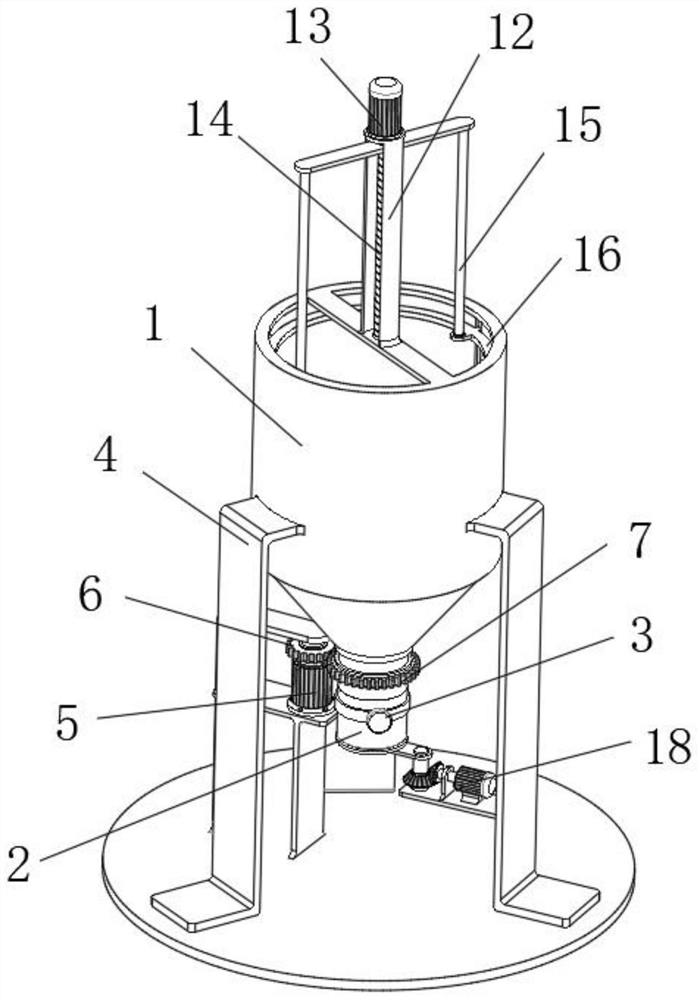

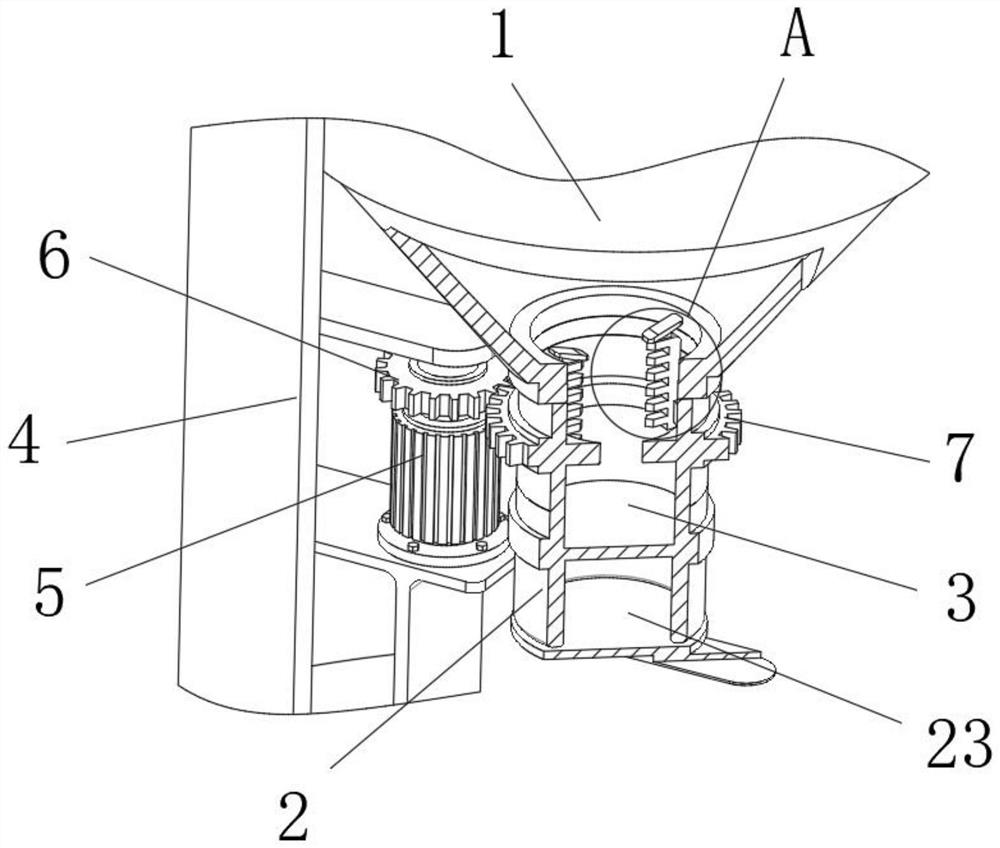

[0030] Example 1, please refer to Figure 1-2 , the present invention provides a technical solution: a feeding machine for back glue production that prevents material clogging, comprising a storage tank 1, a discharge pipe 2 is fixedly installed at the bottom of the storage tank 1, and the interior of the discharge pipe 2 is arranged There is a valve 3, a support frame 4 is fixedly installed around the storage tank 1, a motor a5 is fixed on one side of the support frame 4, the output end of the motor a5 is fixedly connected with a driving gear 6, and the surface of the discharge pipe 2 is connected by rotation. There is a driven gear 7. By setting the driving gear 6 and the driven gear 7 which mesh with each other, when the motor a5 drives the driving gear 6 to rotate, the driving gear 6 will drive the driven gear 7 to rotate.

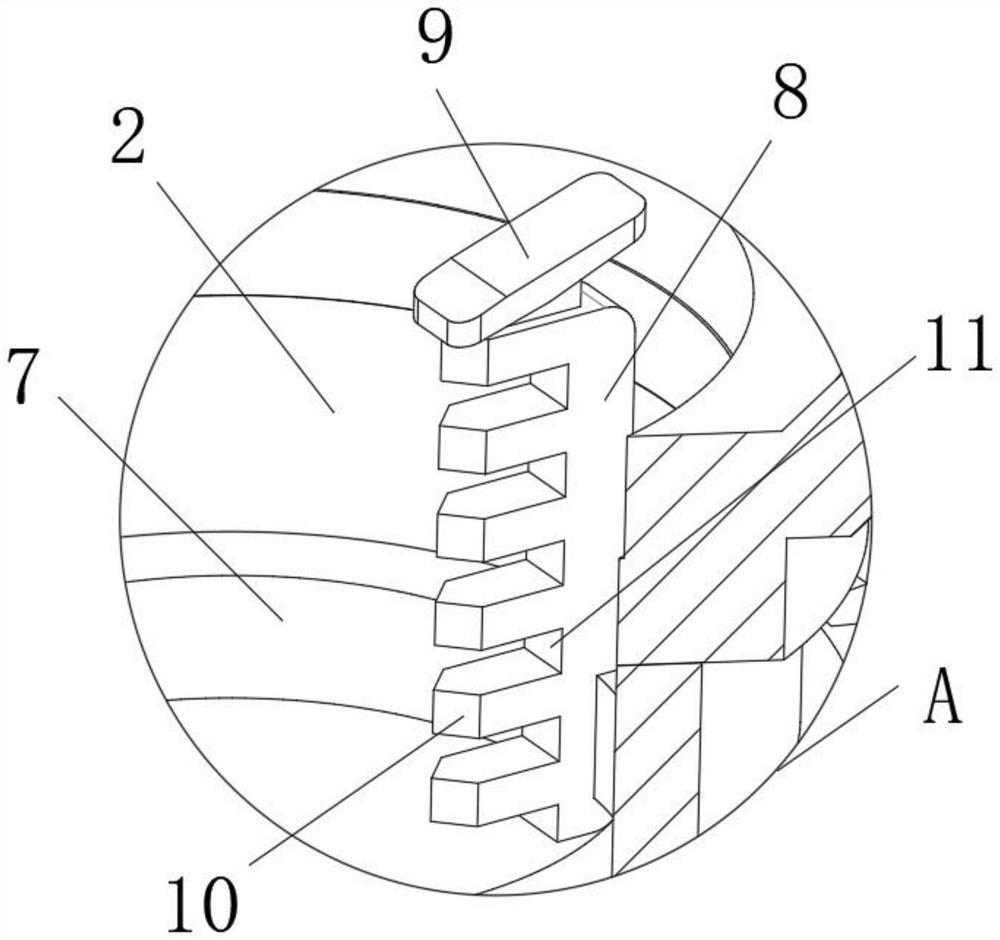

[0031] see Figure 1-3 , One side of the driven gear 7 is equipped with a stirring block 8, and the top surface of the stirring block 8 is equipped w...

Embodiment 2

[0032] Example 2, please refer to figure 1 and Figure 4 , the top surface of the storage tank 1 is provided with a cleaning device, and the cleaning device includes a fixing frame 12. The fixing frame 12 is fixedly mounted on the top surface of the storage tank 1 at the center position, and the top surface of the fixing frame 12 is equipped with a motor b13. The output end of b13 is fixedly connected with a threaded rod 14, a bearing is provided between the threaded rod 14 and the fixing frame 12, the threaded rod 14 is rotatably connected with the fixing frame 12, and the bearing is provided to connect the threaded rod 14 and the fixing frame 12. , so that the threaded rod 14 can rotate smoothly.

[0033] see figure 1 and Figure 4 , the surface of the threaded rod 14 is rotatably connected with a sliding frame 15, the bottom end of the sliding frame 15 is fixedly connected with a scraper 16, the center of the scraper 16 is hollow, and the outer wall of the scraper 16 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com