Connection and disconnection structure of floating production storage and offloading (FPSO) mooring floater and boat body

A technology of floats and hulls, which is applied to ship components, ship construction, floating buildings, etc., can solve the problems of not being able to adapt to the natural environment of the South China Sea, limit the number and form of risers, and high manufacturing costs, so as to achieve easy connection and release, and reduce manufacturing costs. and installation costs, reducing system complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

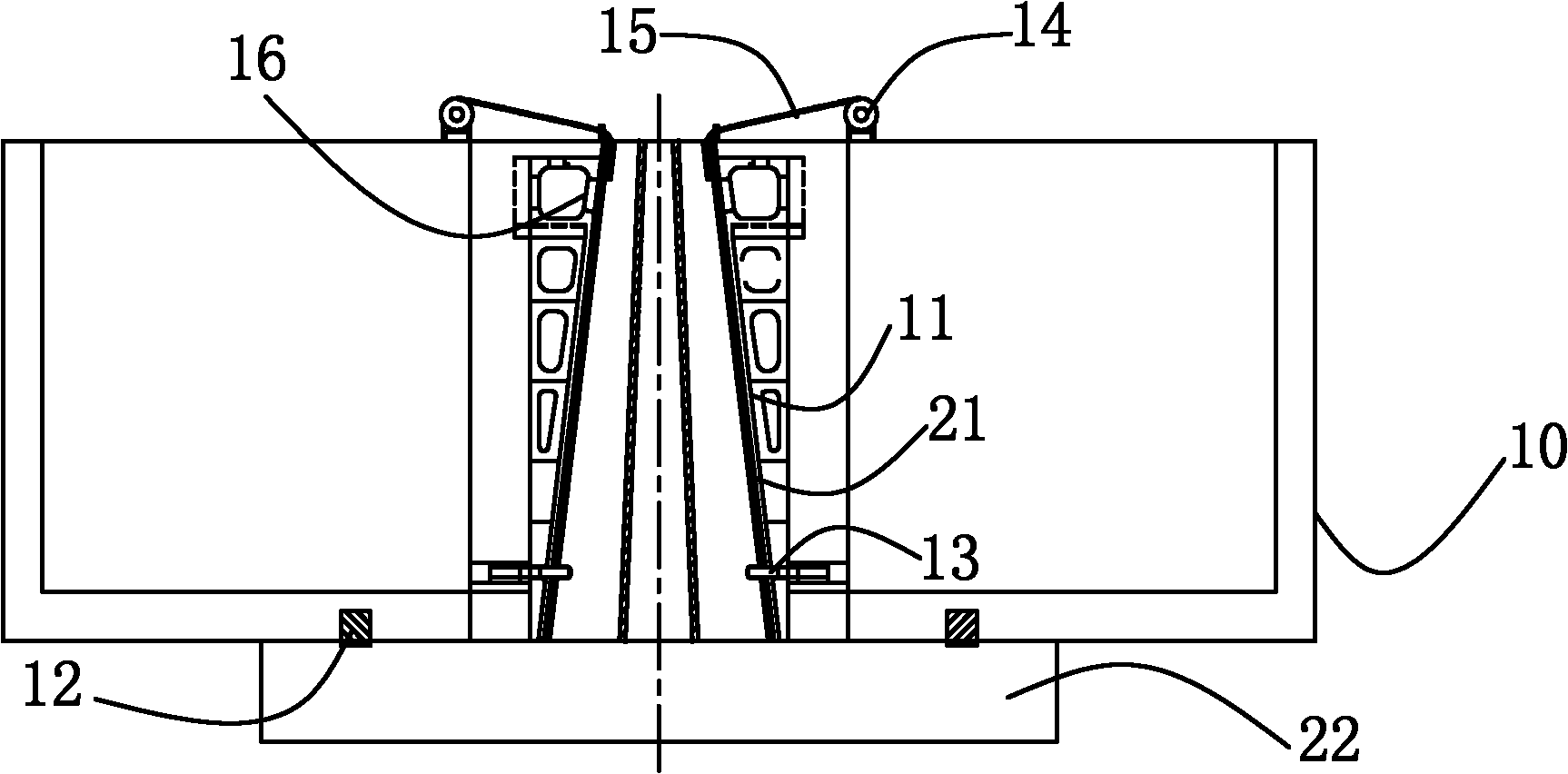

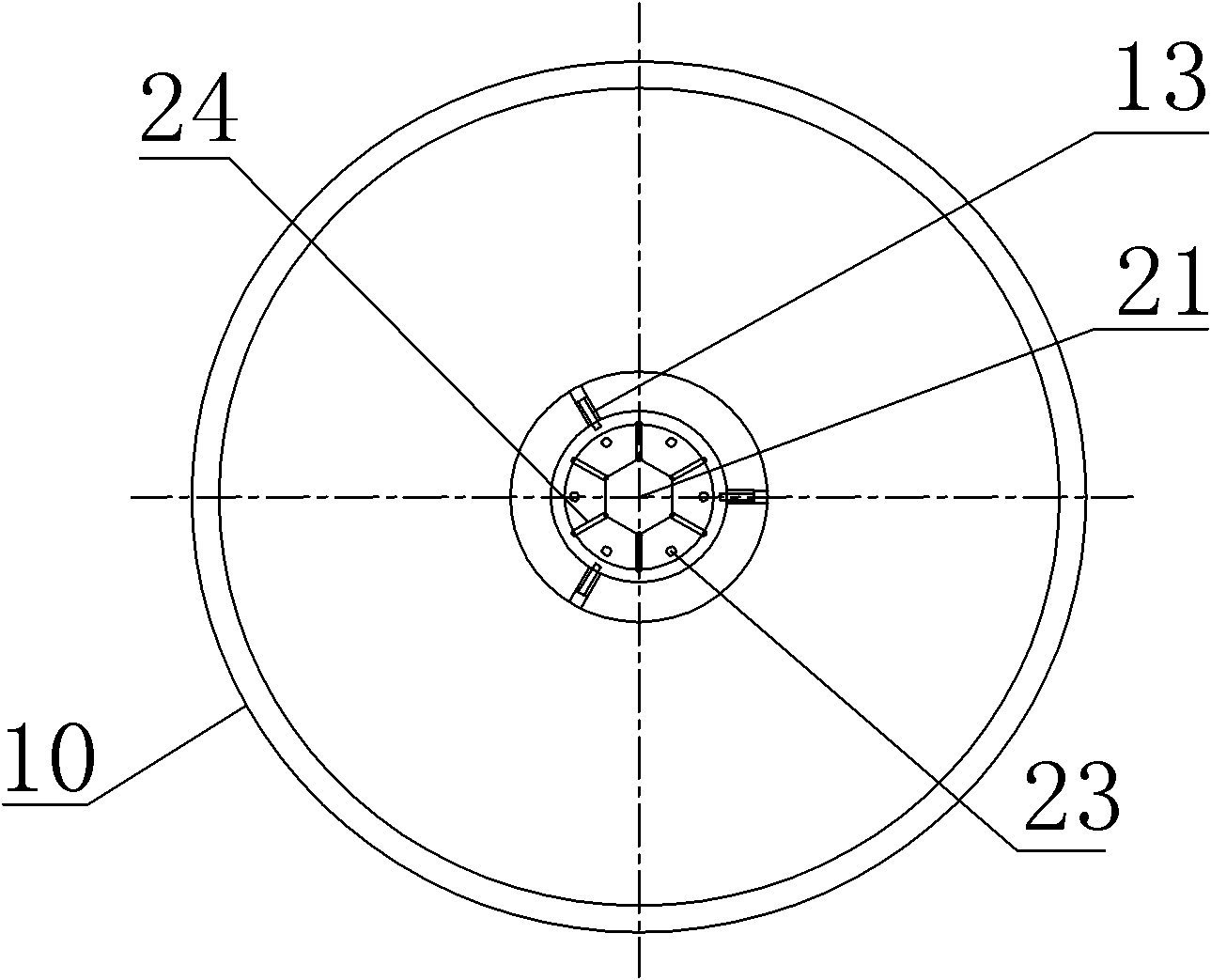

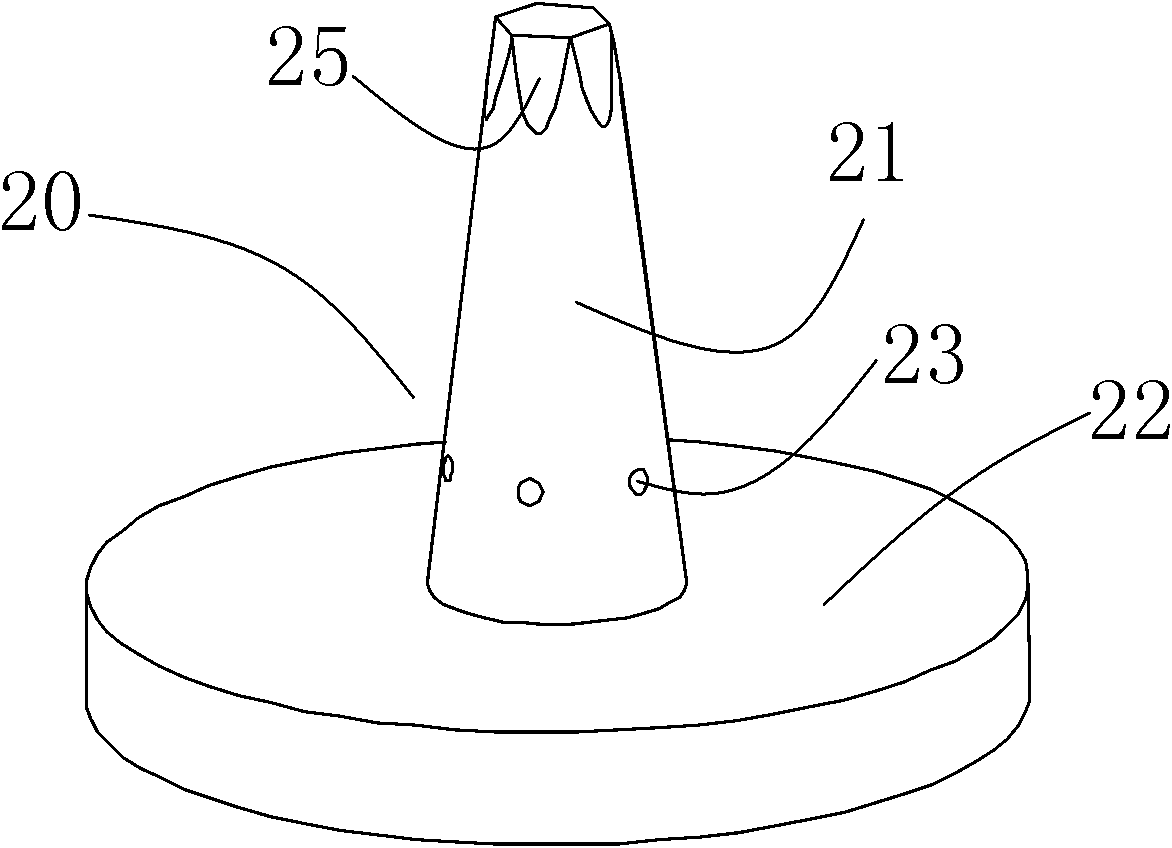

[0029] Such as Figure 1-Figure 4 As shown, the connection and release structure of the FPSO mooring buoy of the present invention and the hull include a hull 10 and a buoy 20, wherein the shape of the buoy 20 is as image 3 As shown, it includes a cone portion 21 and a base 22, and the lower bottom surface of the cone portion 21 is fixed on the base 22. The base 22 of the float is cylindrical, with a sealed cabin inside, which can be filled with water and ballast to realize sinking, and can also be drained and inflated to realize floating. The cone portion 21 of the float is made of a basal cone (truncated cone), but the top of the cone portion 21 is not a circular cross-section. The top face is a regular polygon, forming the shape of "a square and a circle" (or "circle above and below"). Such as Figure 4 As shown, in this embodiment, the top surface of the cone part 21 is a regular hexagon, and the regular hexagon is the inscribed regular hexagon of the apex of the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com