Spiral lifting device for lifting self-lifting platform

A self-elevating platform and helical lifting technology, which is applied in the field of ocean engineering, can solve the problems of small contact area of the meshing surface, large driving load of platform lifting, and occupation of deck space, etc., to achieve small driving load, high structural strength, and easy locking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

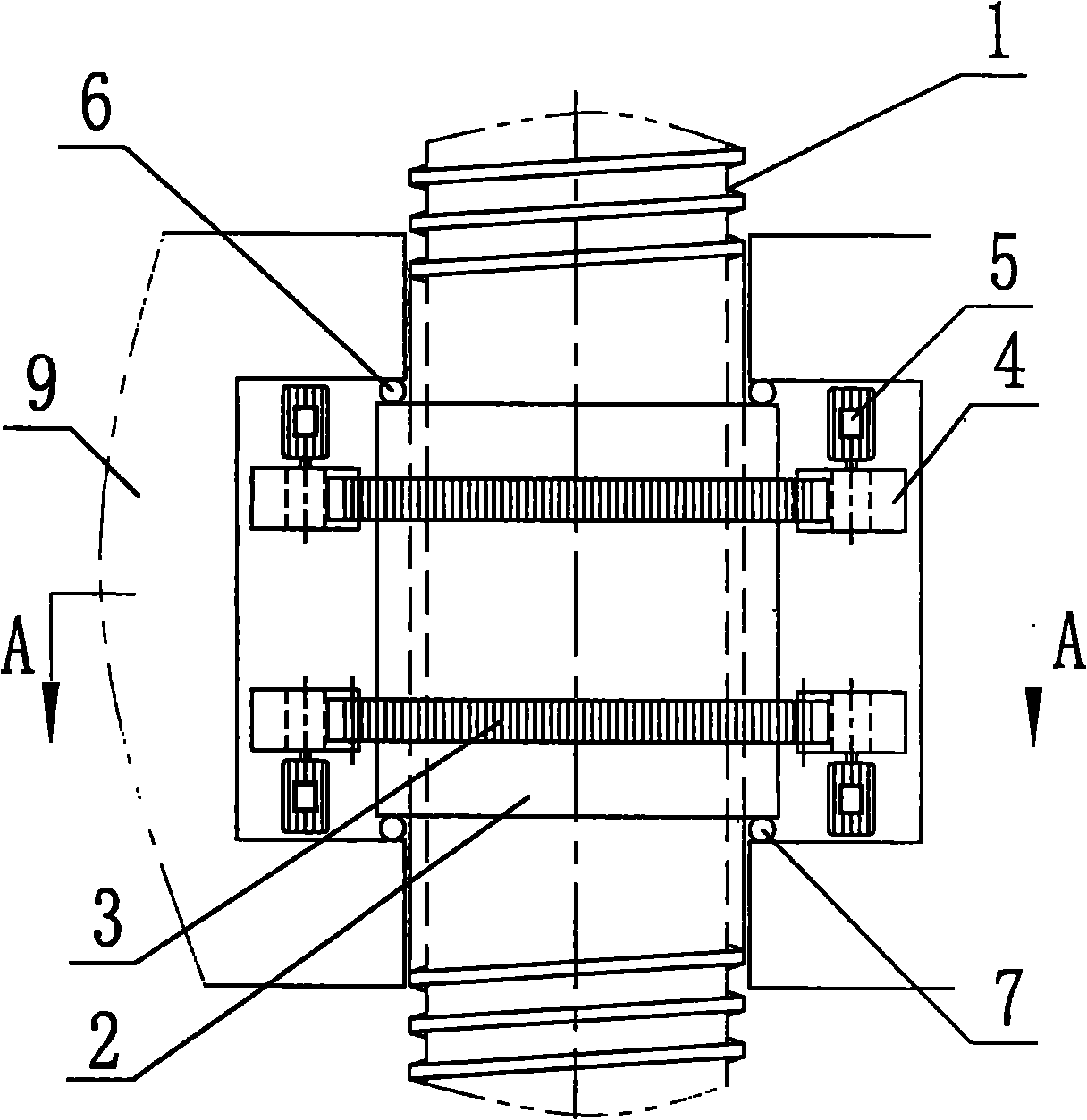

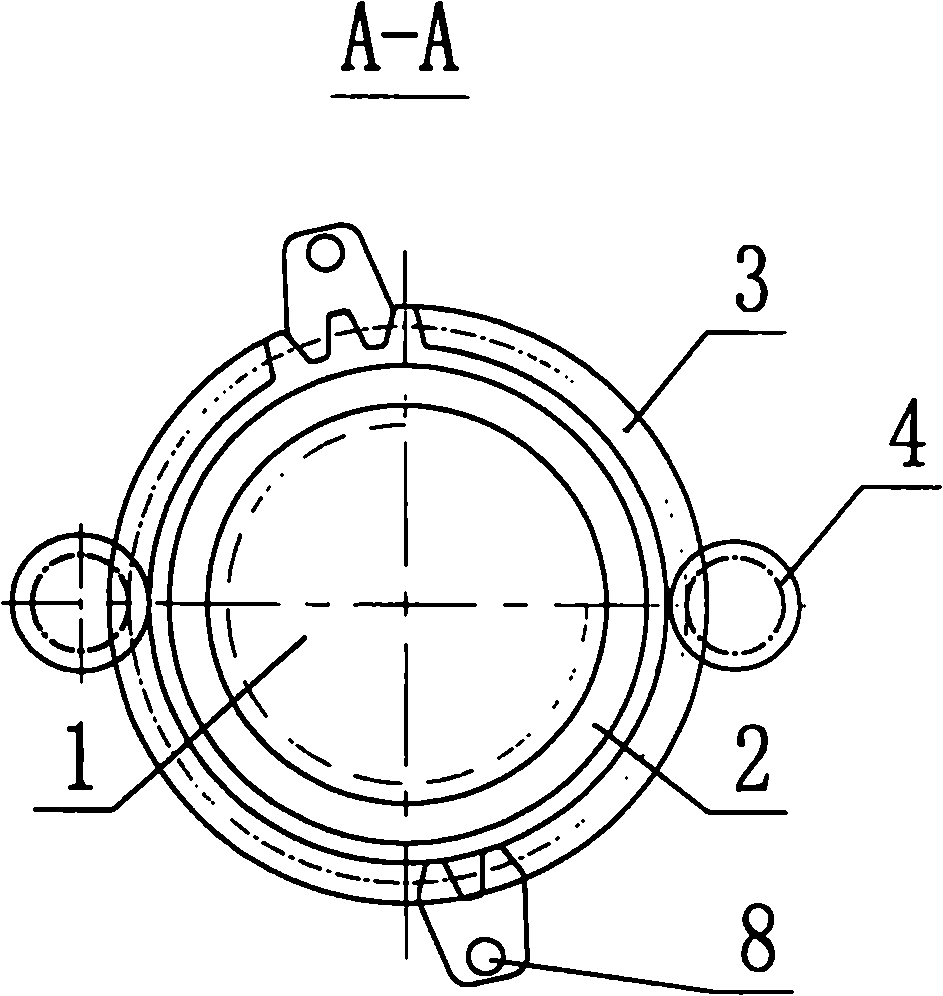

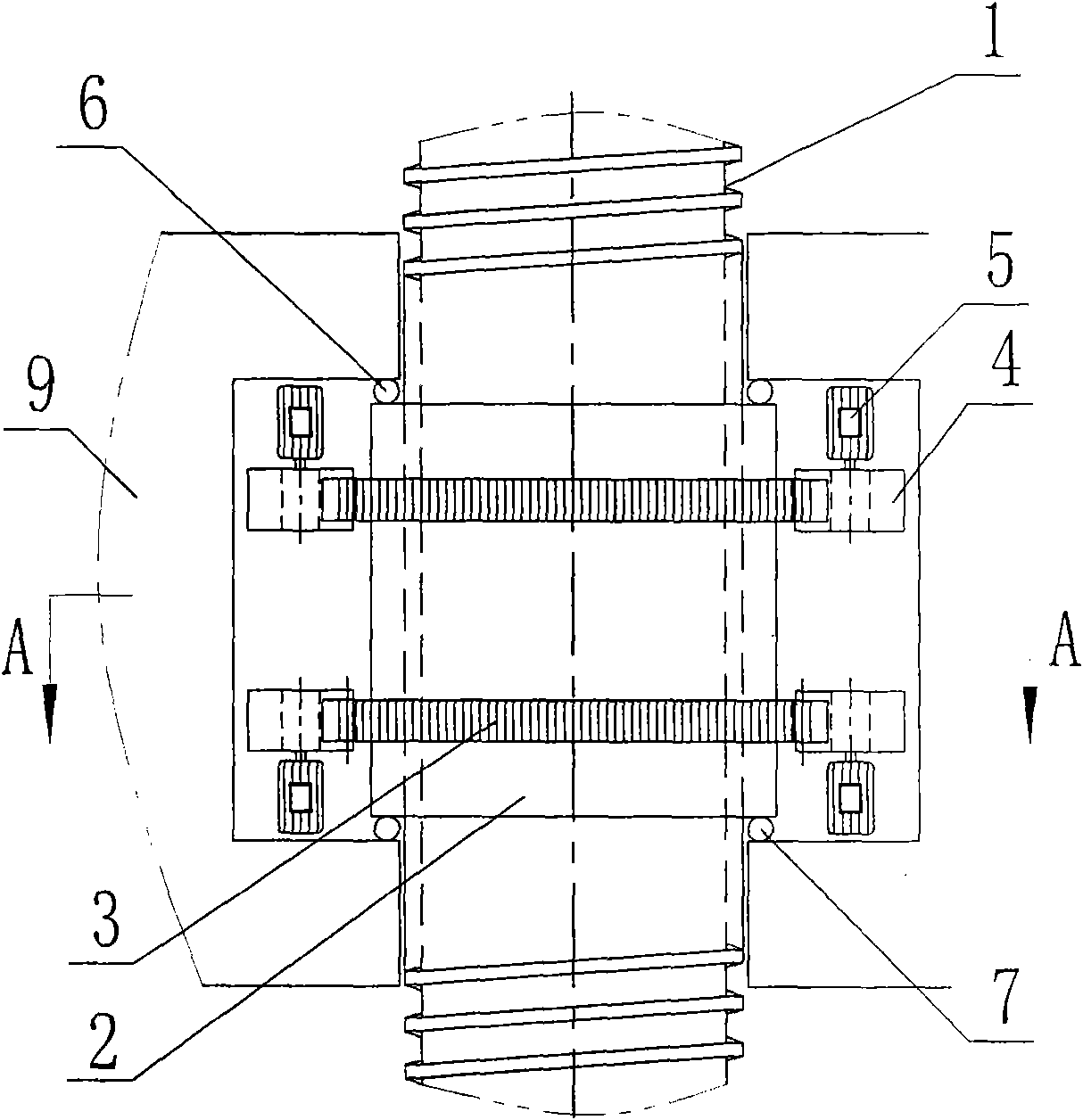

[0010] As shown in the drawings, the present invention mainly includes a pile leg 1 with a spiral guide groove, a spiral guide wheel 2, a ring gear 3, a main gear 4, a driver 5, a top sliding device 6, a bottom sliding device 7, and a locking mechanism 8. One of its characteristics is that the base of the driver 5 is fixed on the platform body 9, the main gear 4 is installed on the output shaft, the ring gear 3 is fixed on the outer ring of the spiral guide wheel 2, the main gear 4 is meshed with the ring gear 3, and the gear with the spiral guide groove The leg 1 passes through the inner hole of the helical guide wheel 2 and engages with the helical guide wheel 2 for transmission. The driver 5 drives the helical guide wheel 2 to rotate relative to the leg 1 with the helical guide groove to realize the vertical lifting of the platform body 9 . Two of its feature is that the spiral guide wheel 2 can be one, two, three or four. The third feature is that each spiral guide wheel 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com