Keel connecting device based on suspended curtain wall

A connecting device and hanging technology, applied in the field of building curtain wall systems, can solve problems such as affecting the overall appearance of the curtain wall, inconvenient cleaning, and falling curtain wall panels, so as to improve reliability and safety, improve connection stability, and improve connection. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

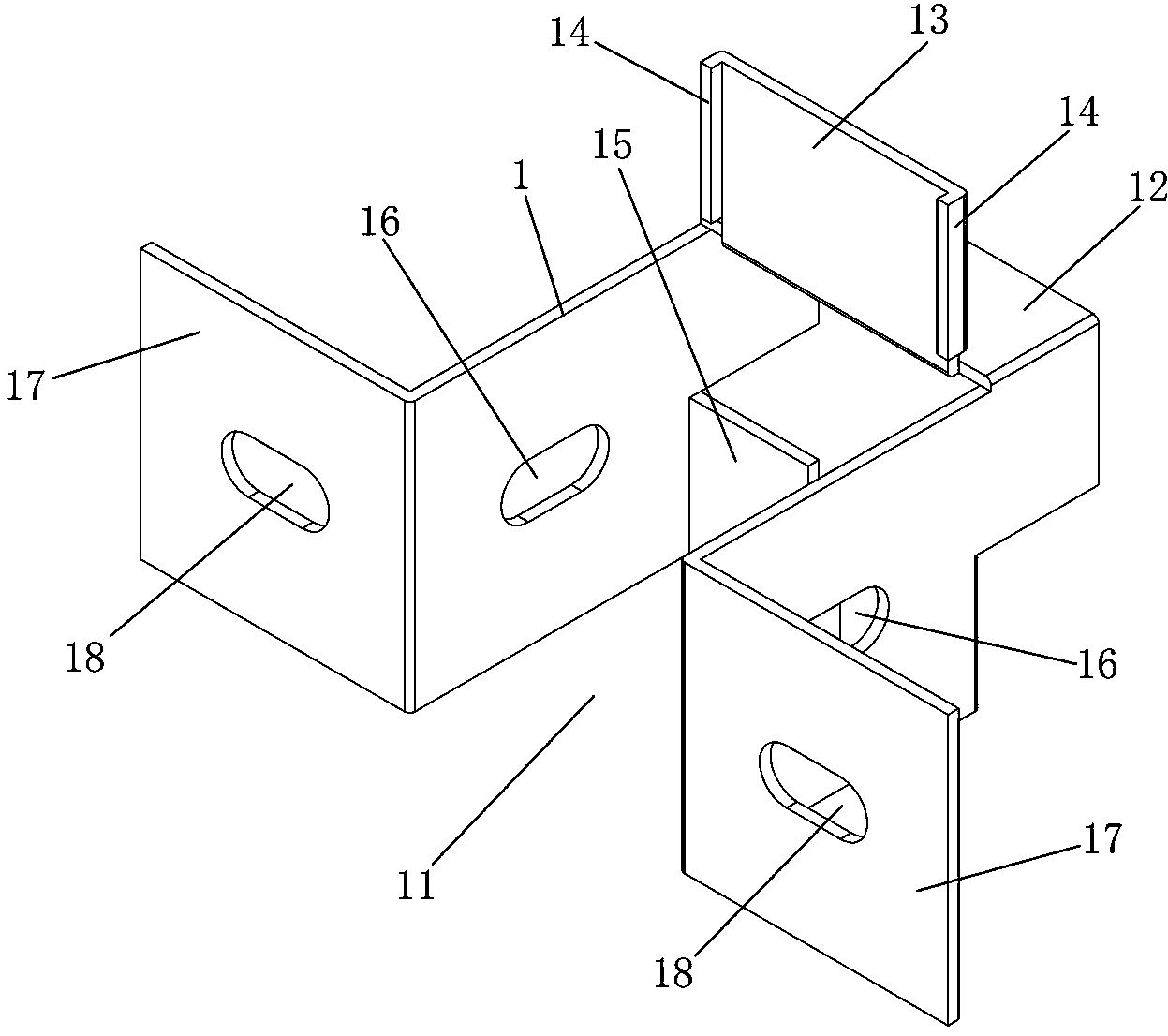

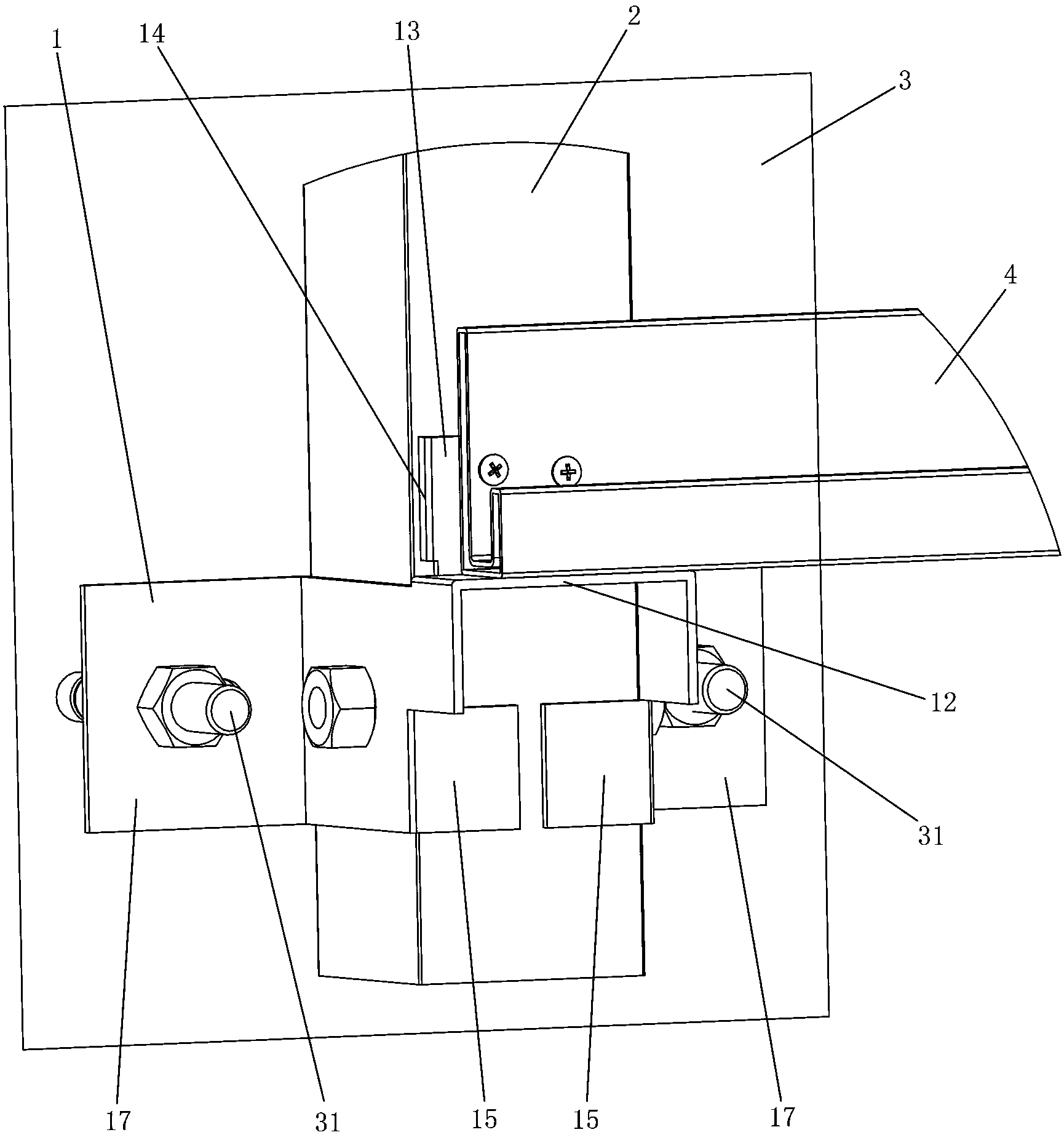

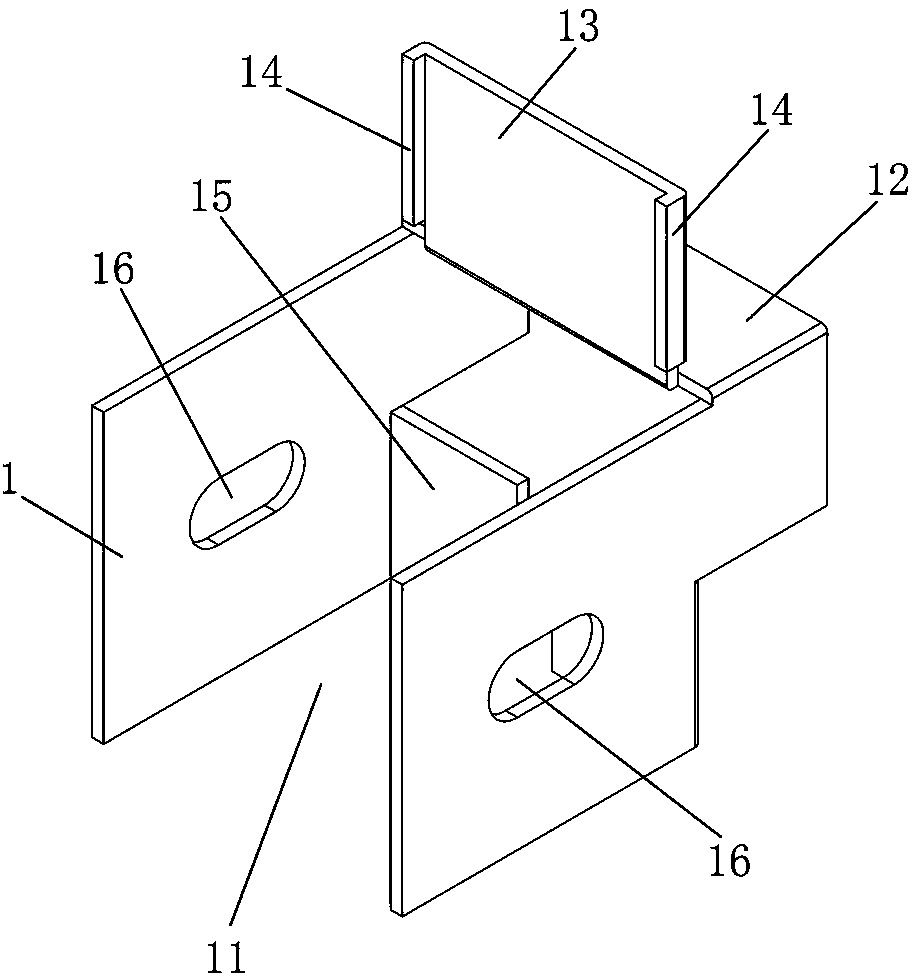

[0020] figure 1 and figure 2 An embodiment of a keel connecting device based on a hanging curtain wall of the present invention is shown. The keel connecting device includes a connector body 1. The connector body 1 is provided with a vertical keel accommodating portion 11, and the front end of the vertical keel accommodating portion 11 is provided with a vertical keel accommodating portion 11. There is a horizontal keel support platform 12, when installing the horizontal keel 4, the horizontal keel 4 can be placed on the horizontal keel support platform 12, and the horizontal keel support platform 12 is used to carry the horizontal keel 4 and be installed on the upper curtain wall of the horizontal keel 4. The weight of the plate, so that the self-tapping screws and other fasteners connecting the horizontal keel 4 and the vertical keel 2 do not need to bear the shear force, which can greatly improve the stress of the fasteners at this place, and improve the strength of the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com