Charging method for vehicle lead-acid storage battery

A lead-acid battery and charging method technology, applied in the direction of secondary battery charging/discharging, secondary battery repair/maintenance, etc., can solve the problems of poor battery charging effect, battery can not be charged, capacity attenuation, etc. Longevity, strong practicability and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

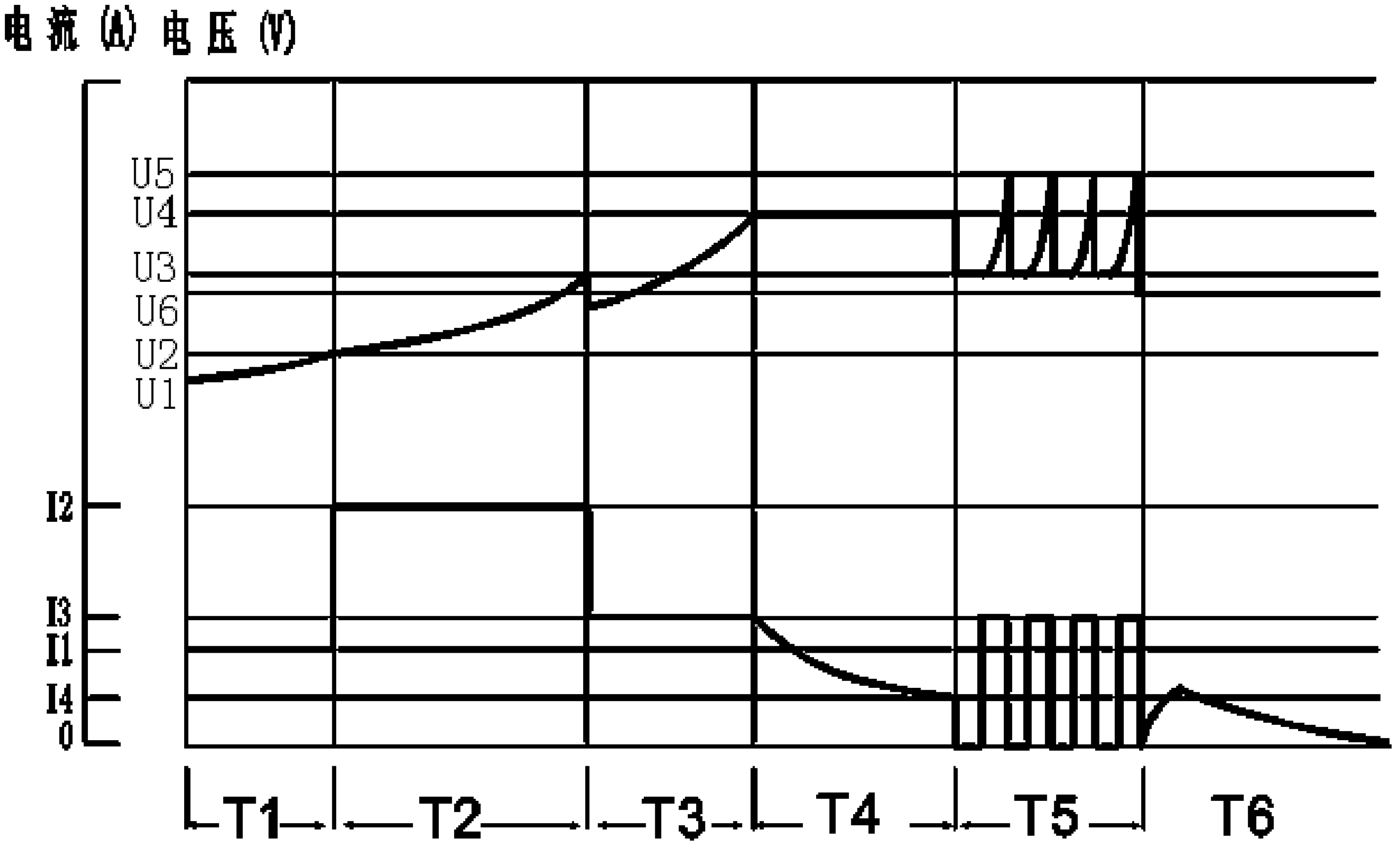

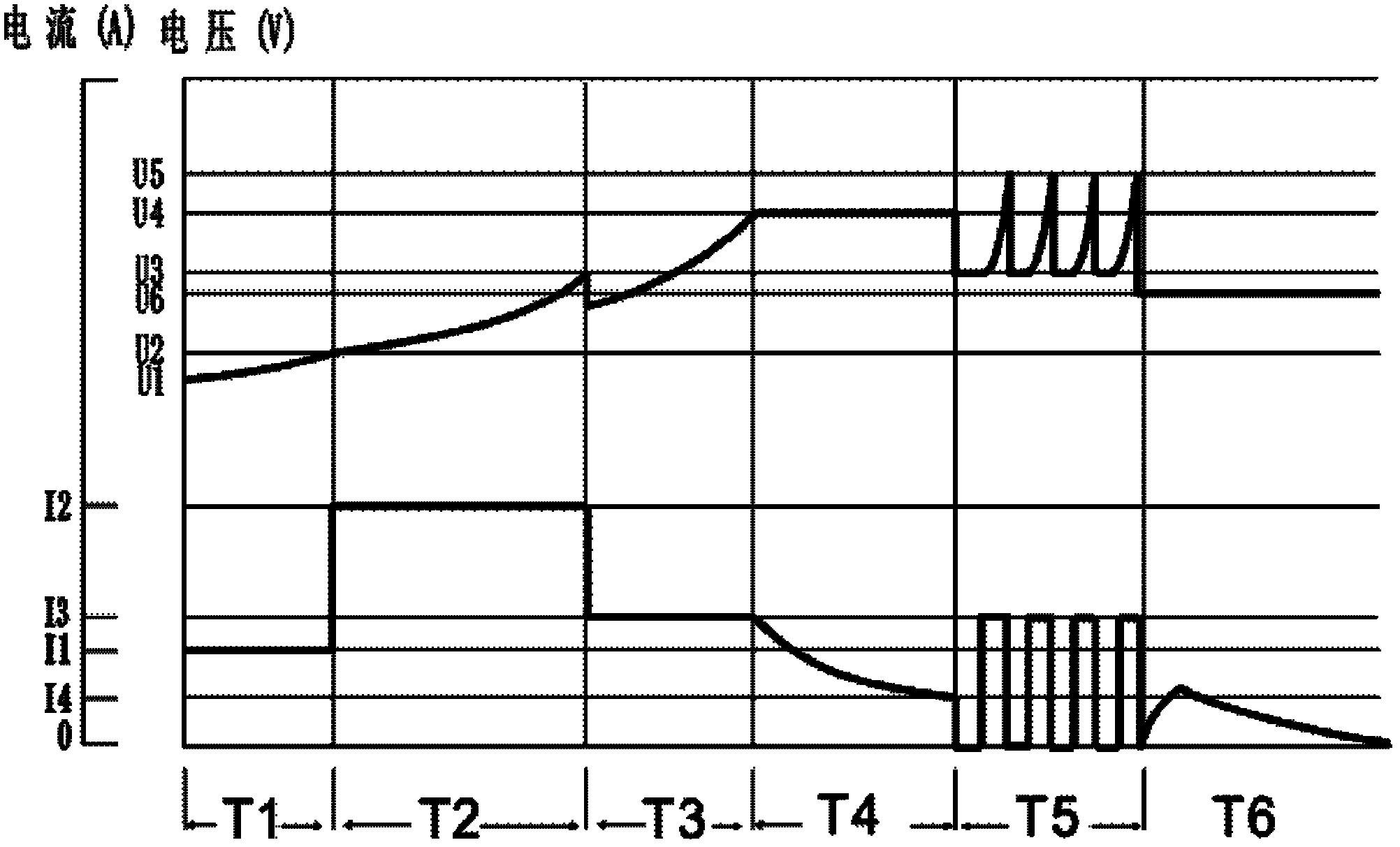

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] figure 1 It is to illustrate the various stages of the charging method more clearly and reflect it with intuitive graphics.

[0021] The first stage (T1): small current constant current charging. Charge with I1 constant current until the voltage reaches U2.

[0022] U1=1.97V / cell, as the basis for judging whether this stage works, when the voltage of a single cell is lower than this value, this stage starts. Otherwise, this stage will not start (directly enter the second stage);

[0023] U2=2V / single cell;

[0024] I1=0.05C~0.08*C ampere.

[0025] Phase two (T2): Constant current charging. Charge with I2 constant current until the voltage reaches U3. Time: 5-6 hours.

[0026] U3=2.40V / cell;

[0027] I2=0.2*C amps.

[0028] Three-stage (T3): Constant current charging with reduced current. Charge with I3 constant current until ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com