Laser cutting head displacement sensor with multi-point measurement function

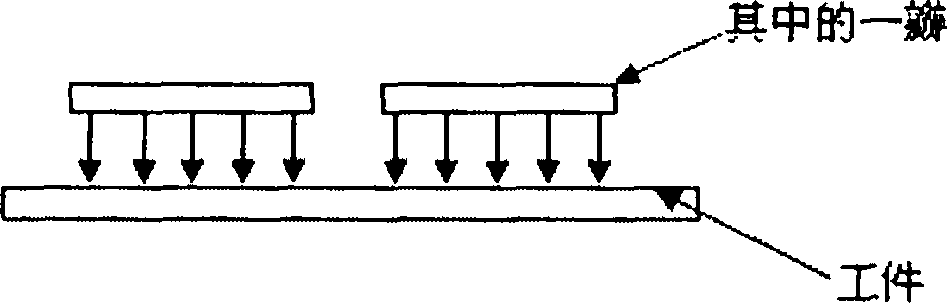

A laser cutting head, multi-point measurement technology, applied in laser welding equipment, manufacturing tools, welding equipment and other directions, to simplify the teaching process, easy posture, and improve detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

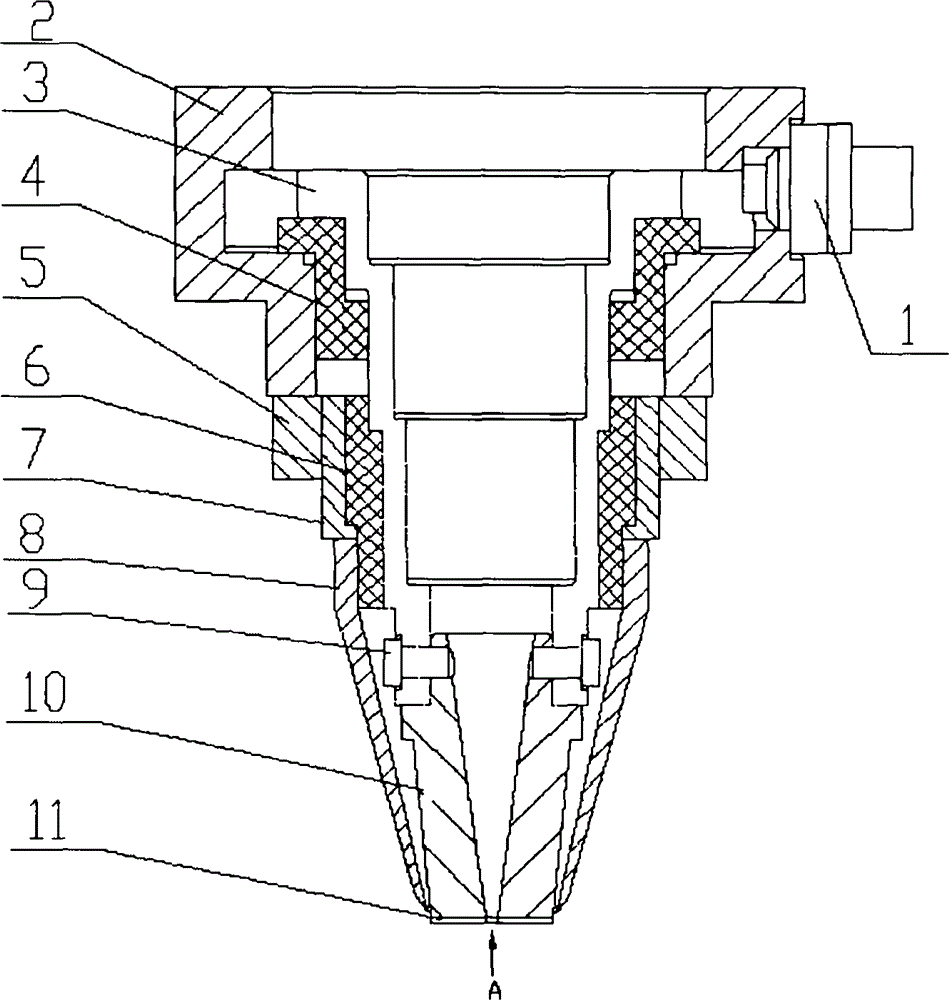

[0022] The structure of the laser cutting head displacement sensor of the present invention mainly includes: a sensing line connector 1, a connecting seat 2, a split metal connecting sleeve 3, a fixed insulating sleeve 4, a fixed shielding cover 7, a movable shielding cover 8, a laser cutting head The nozzle 10 etc., wherein the split nozzle 10 and the induction plate 11 are the main design parts of the present invention. The connecting seat 2 is used to connect with the components on the sensor, the sensor line connector 1 is arranged on the side of the connecting seat 2, and is used to transmit the signal of the sensor to the control system, and the split metal connecting sleeve 3 is inside the connecting seat 2, and the The effect of the wire, because if the lead wire is used, it may cause the lead wire to move and rotate. In order to insulate the connecting sleeve 3 from other parts, a fixed insulating sleeve 4 is provided between the connecting sleeve 3 and the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com