Box type corrector for heat transfer printing equipment

A printing equipment and thermal transfer printing technology, applied in printing devices, printing, etc., can solve problems such as irregular arrangement of pharmaceutical packaging boxes, lower product qualification rate, and increase production costs, and achieve simple structure, improved production efficiency, and reduced printing costs. The effect of the error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

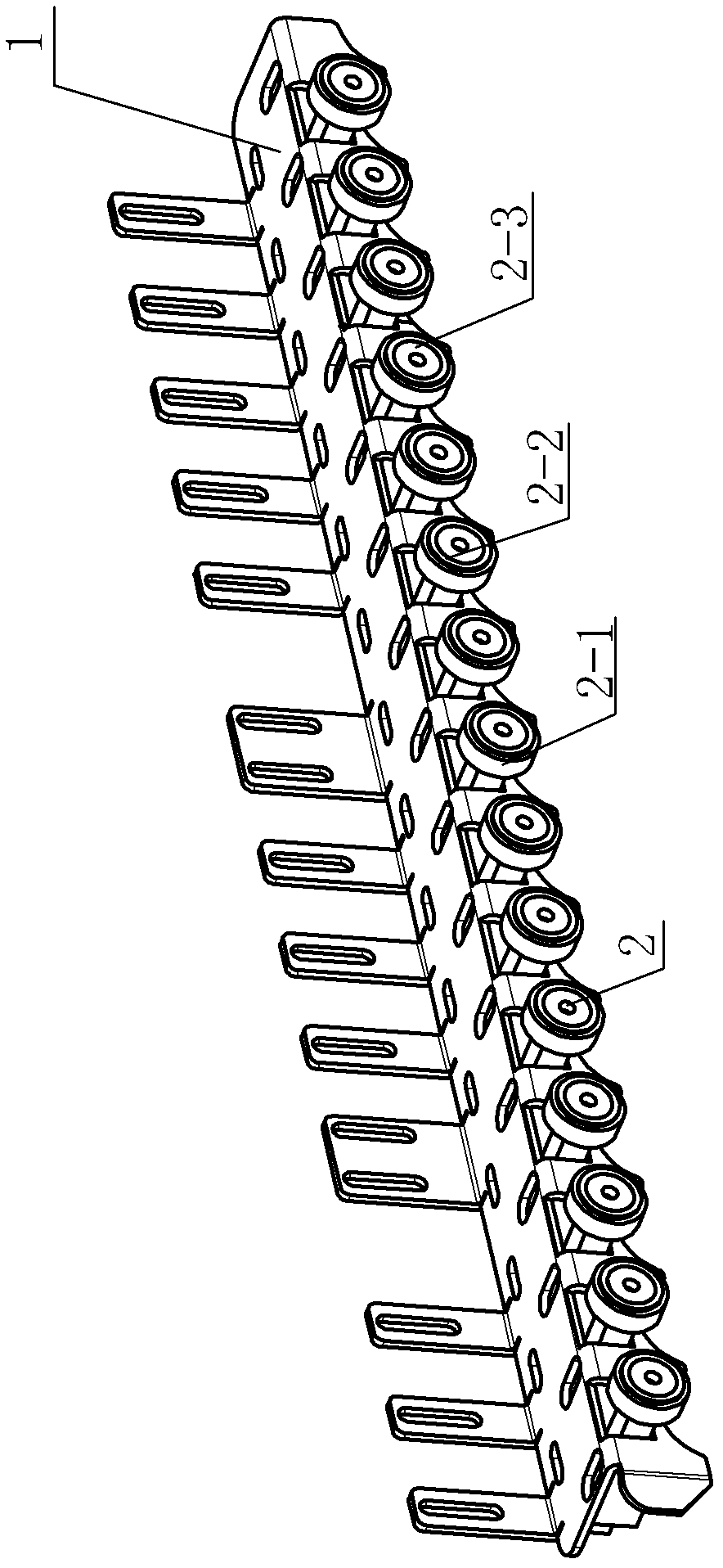

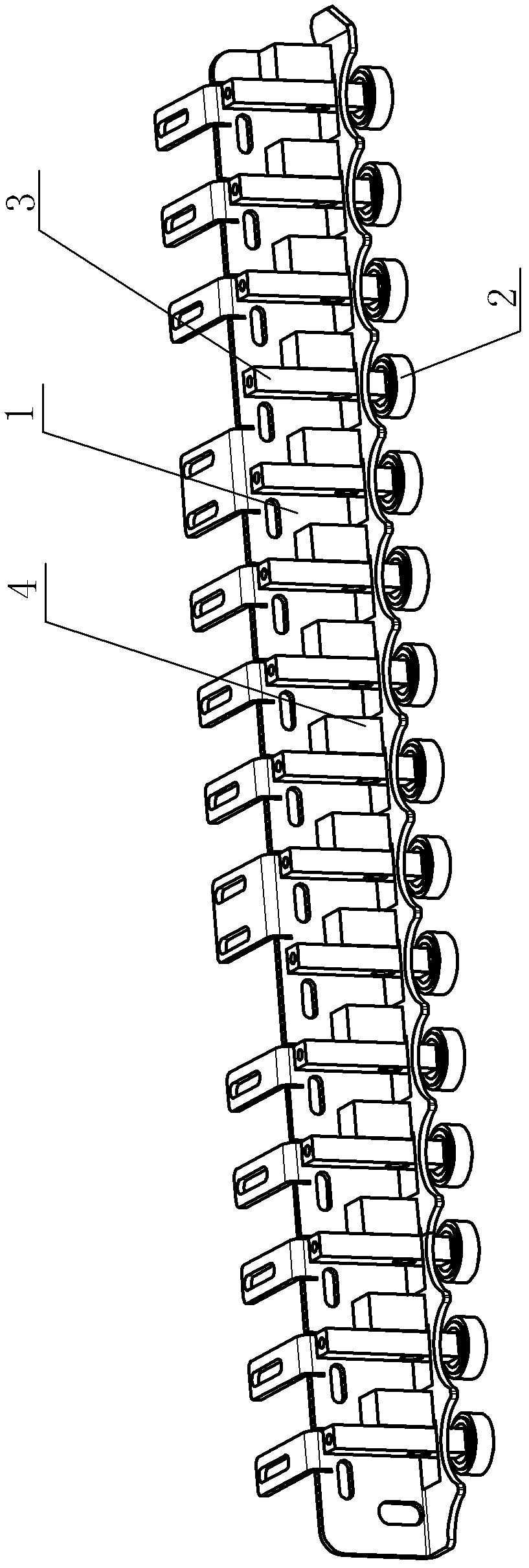

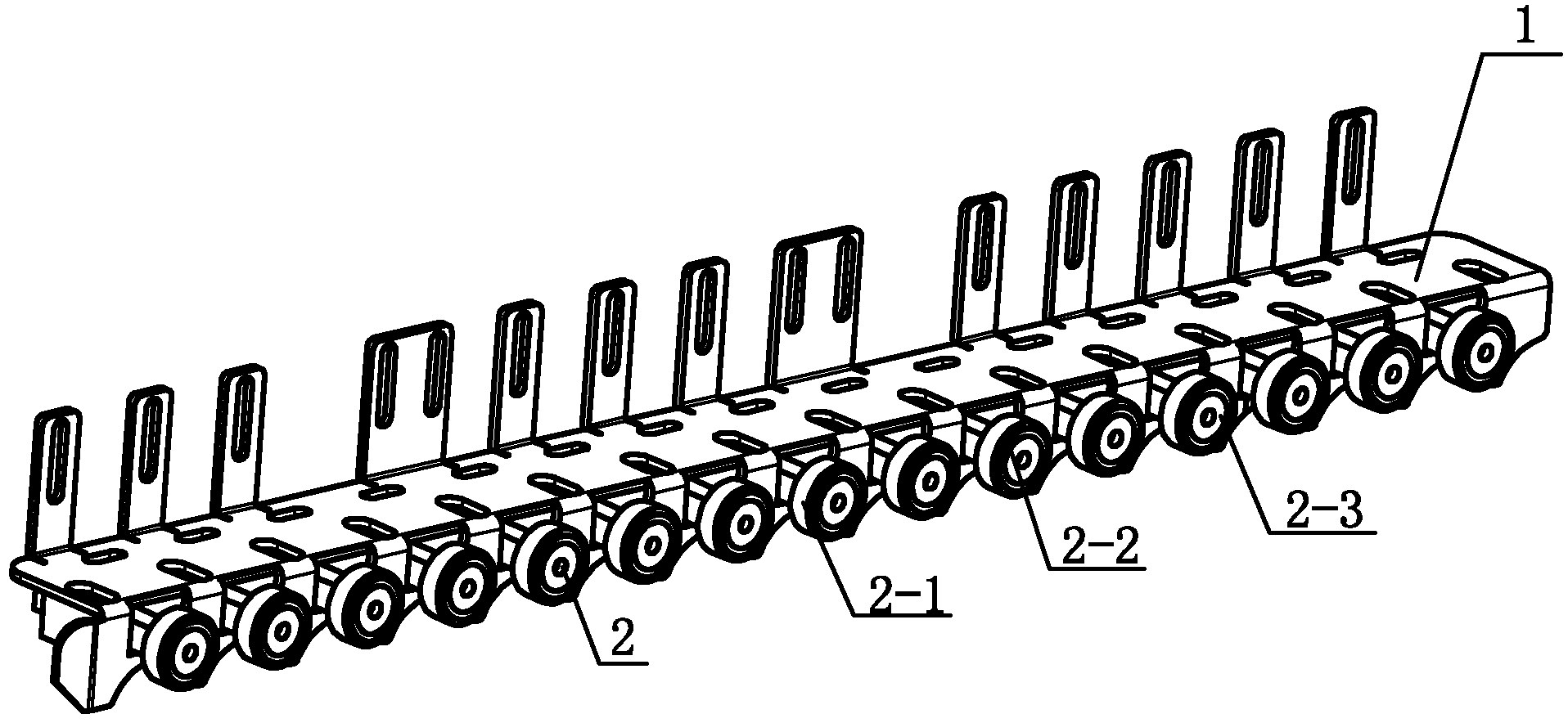

[0007] Specific implementation mode 1: Combination figure 1 To explain this embodiment, the box-shaped correction device for thermal transfer printing equipment described in this embodiment includes a correction bracket 1, a number of roller assemblies 2, a number of connecting rods 3, and a number of connecting blocks 4, and a number of connecting rods 3. They are arranged side by side and parallel on the correcting bracket 1, one side of each connecting rod 3 is provided with a connecting block 4, and a roller assembly 2 is installed on the head of each connecting rod 3 respectively. This embodiment can arrange the packaging boxes running on the driving drum in an orderly arrangement, so that the packaging boxes enter the printing unit one by one for printing, which reduces the printing error rate and improves the production efficiency. The invention has a simple structure and a production cost. Easy to maintain and operate.

specific Embodiment approach 2

[0008] Specific implementation manner two: combination figure 2 To illustrate this embodiment, each roller assembly 2 of the box-shaped correction device for thermal transfer printing equipment described in this embodiment includes a silicone ring 2-1, a bearing sleeve 2-2, and a bearing 2-3. The bearing sleeve 2-2 is sleeved on the bearing 2-3, the silicone ring 2-1 is sleeved on the bearing sleeve 2-2, and the bearing sleeve 2-2 is installed on the head of the connecting rod 3. The silicone ring 2-1 in this embodiment increases the friction between the roller assembly 2 and the outer surface of the driving drum. The other components and connection relationships are the same as in the first embodiment.

[0009] working principle

[0010] The present invention is installed on the thermal transfer printing device, the outer edge of the silicone ring 2-1 is in contact with the outer surface of the driving roller, the driving roller drives the roller assembly 2 to rotate through fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com