Adaptive front lighting system (AFS) horizontal angle adjustment actuating mechanism

A technology for adjusting execution and horizontal angle, applied in optical signals, signal devices, transportation and packaging, etc., can solve the problems of low control accuracy, high production cost, large installation space, etc., and achieve high control accuracy, simple structure, and installation space. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

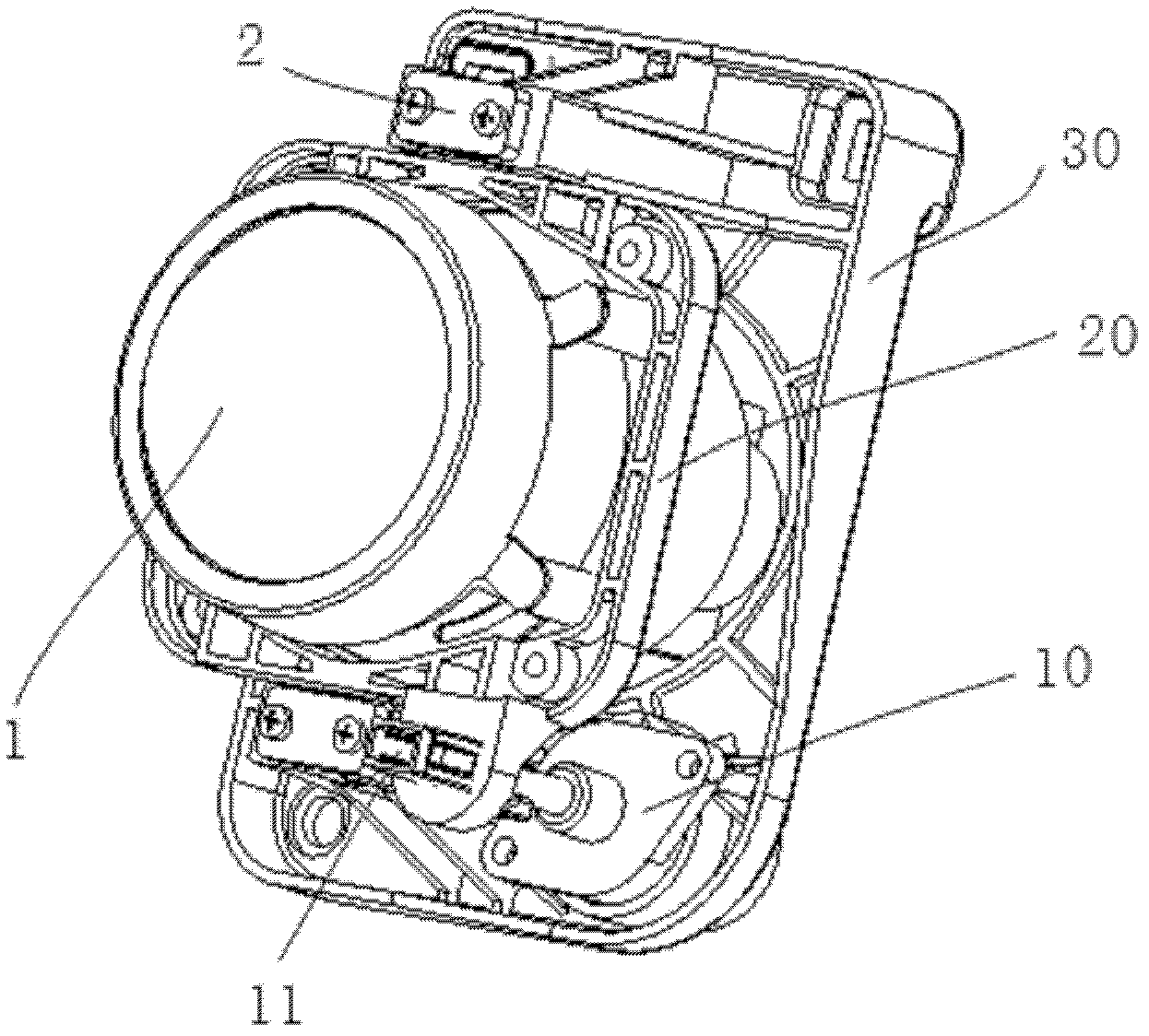

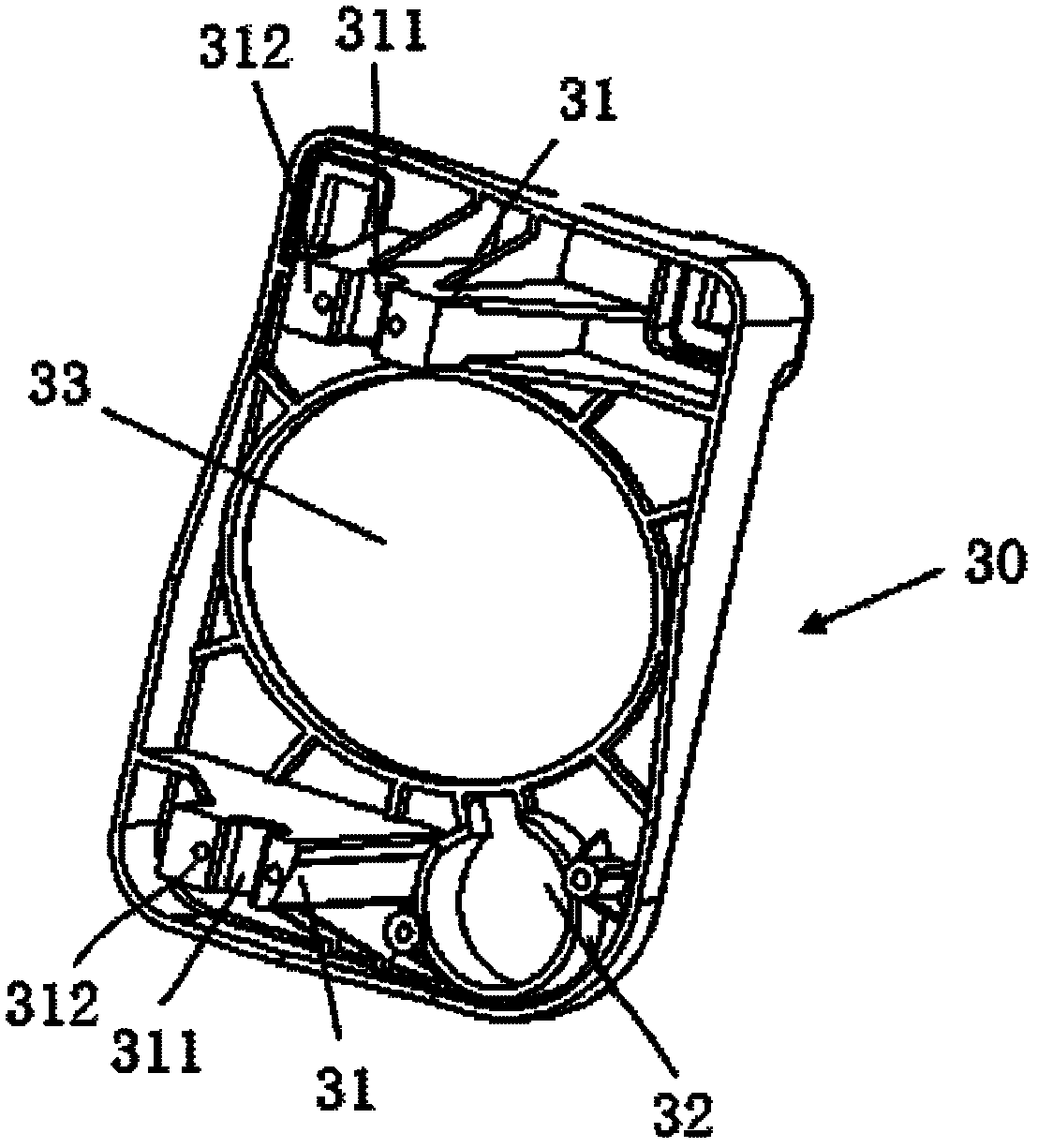

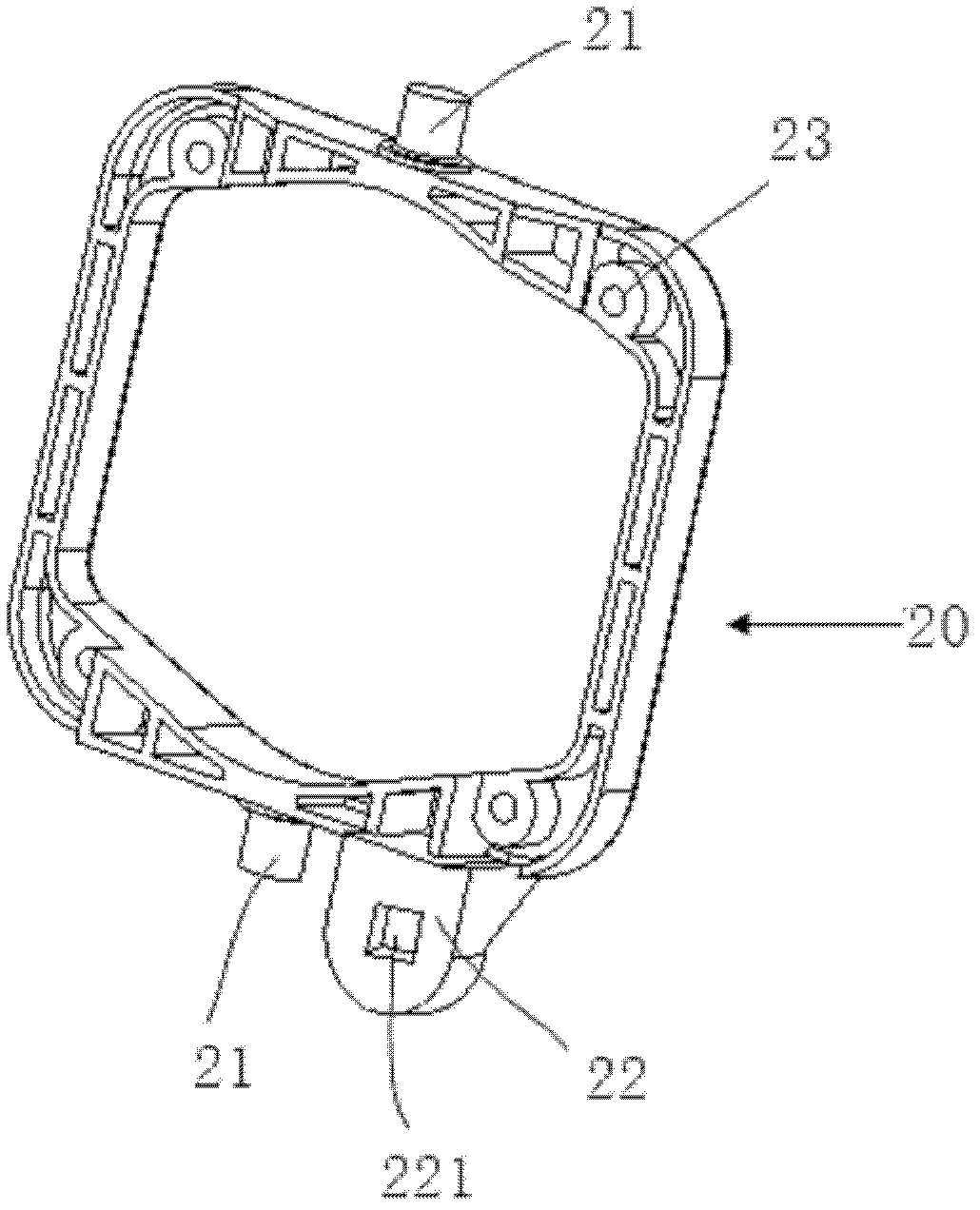

[0013] An AFS horizontal angle adjustment actuator includes a lighting assembly 1 and a base 30 for fixing the lighting assembly 1. The lighting assembly 1 is connected with a driving device 10 for driving the lighting assembly 1 to rotate left and right. The lighting assembly 1 is fixed on the base 30, the driving device 10 is connected with the lighting assembly 1, and the driving device 10 makes a forward and backward movement, thereby driving the lighting assembly 1 to rotate left and right along its own rotation axis. Driving the lighting assembly 1 to rotate can realize the adjustment of the small angle rotation of the lighting assembly 1 . Here, the front and rear directions refer to the directions in which the front and the rear of the vehicle are located, respectively.

[0014] like figure 1 As shown, the lighting assembly 1 is provided with a fixing frame 20 outside, and the fixing frame 20 is connected with the driving device 10 . The lighting assembly 1 and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com