Laser cutting device for large irregular pipe cross section

A pipe section and laser cutting technology, which is applied to laser welding equipment, tubular objects, applications, etc., can solve the problems of heavy and complicated clamping, inability to adjust, and slow cutting speed, so as to improve operation efficiency, cutting efficiency, and high work efficiency , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

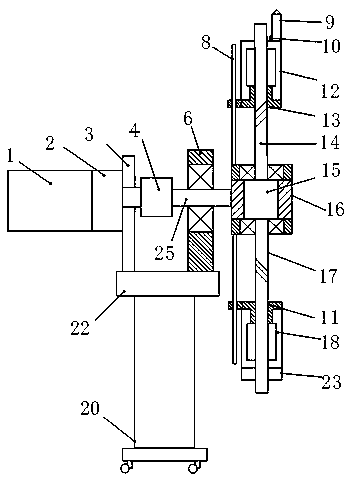

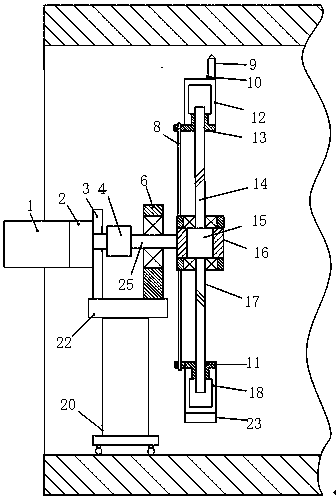

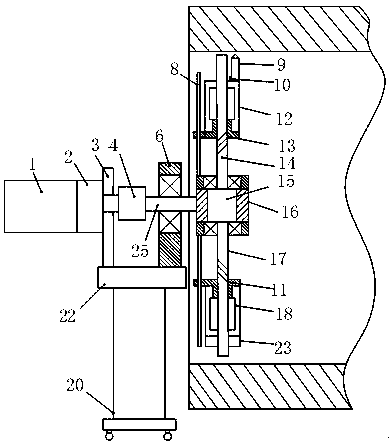

[0013] The present invention is described in detail below in conjunction with accompanying drawing:

[0014] like figure 1 , figure 2 and image 3 , the present invention provides a laser cutting device for large irregular pipe sections, including a drive motor 1, a reducer 2, a mounting seat 3, a coupling 4, a bearing seat 6, a guide rod 8, a laser cutting head 9, and an infrared distance sensor 10. Right-handed sleeve 12, right-handed nut 13, right-handed screw 14, motor rotor 15, motor stator 16, left-handed nut 11, left-handed screw 17, left-handed sleeve 18, movable base 20, support platform 22, Balance counterweight 23, drive shaft 25; mounting seat 3 is fixed on support platform 22, drive motor 1 is directly connected with reducer 2, and is fixedly installed on mounting seat 3, and mounting seat 3 and bearing seat 6 are fixedly installed on support platform 22, the supporting platform 22 is installed on the movable base 20; the transmission output shaft and the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com