Lifting clamping device for car door conveying line

A clamping device and conveying line technology, applied in the field of hoisting clamping devices, can solve problems such as poor reliability, potential safety hazards, and car doors falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

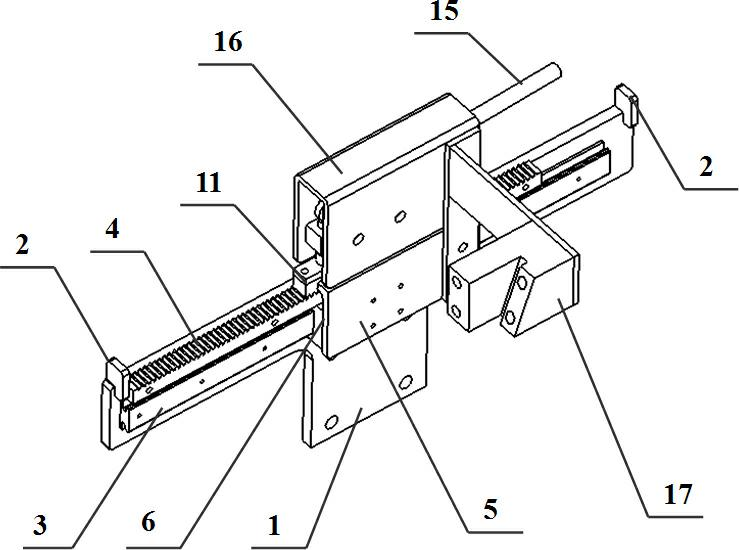

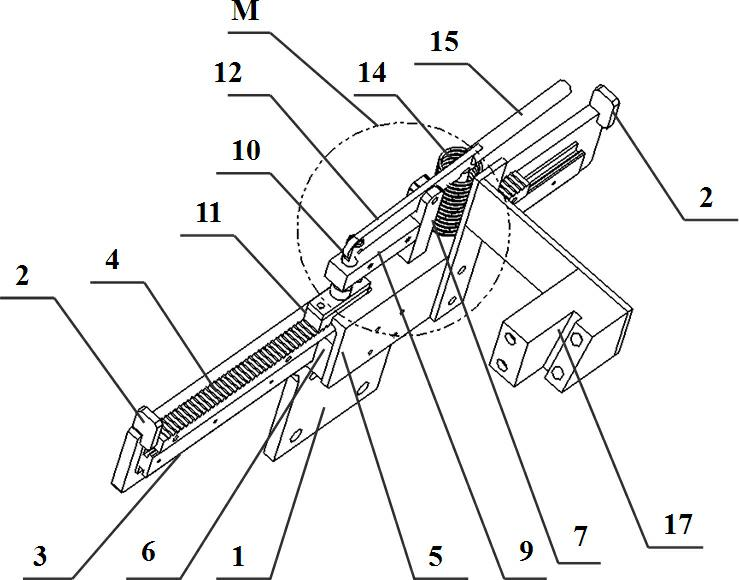

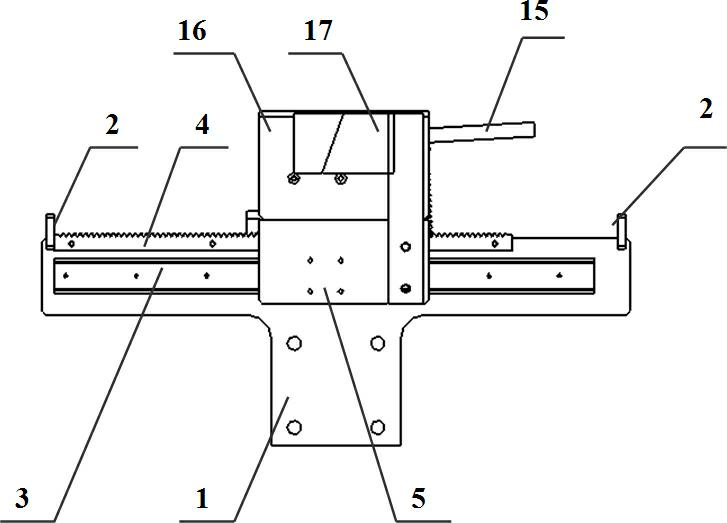

[0025] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , a lifting and clamping device for a car door conveying line, comprising a fixing bracket 1;

[0026] Fixed support 1 is " T " font steel plate, and the two ends of the top surface of its upper cross bar are fixedly connected with stopper 2 respectively. The lower rack 4 is fixedly connected to one side of the upper crossbar of the fixed bracket 1 by screws, and the tooth surface of the lower rack 4 is parallel to the top surface of the upper crossbar of the fixed bracket 1 and slightly higher than the top surface of the upper crossbar . The fixed rail 3 is fixedly installed on the fixed bracket 1 below the lower rack 4 and is parallel to the lower rack 4 . The outer surface of the fixed track 3 is provided with a T-shaped guide rail in cross section.

[0027] Cooperating with the T-shaped guide rail of the fixed track 3, the slide rail 6 is connected, see Figure 6 , the slide rail 6 is fixedly inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com