Detachable support structure for clothes dryer

A support structure and technology for clothes dryers, which are applied in the directions of household clothes dryers, applications, household appliances, etc., can solve the problems of limited bending and torsional strength, unsightly reinforcement ribs, increased size of clothes rails, etc. To achieve the effect of not easy to store dust, easy to store in packaging and transportation, and reduce packaging volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Such as Figure 2A-2E Shown is a preferred embodiment of the present invention.

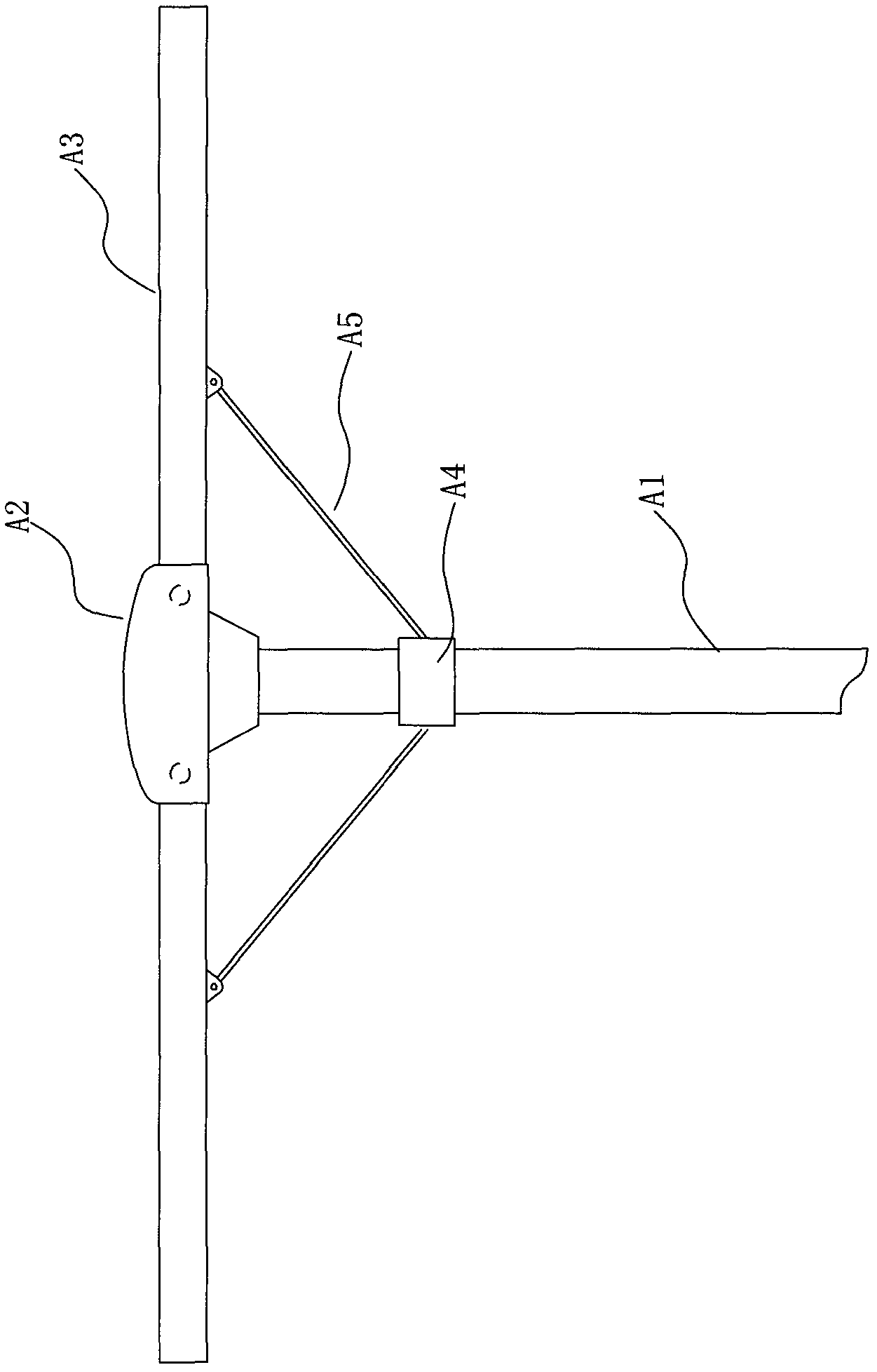

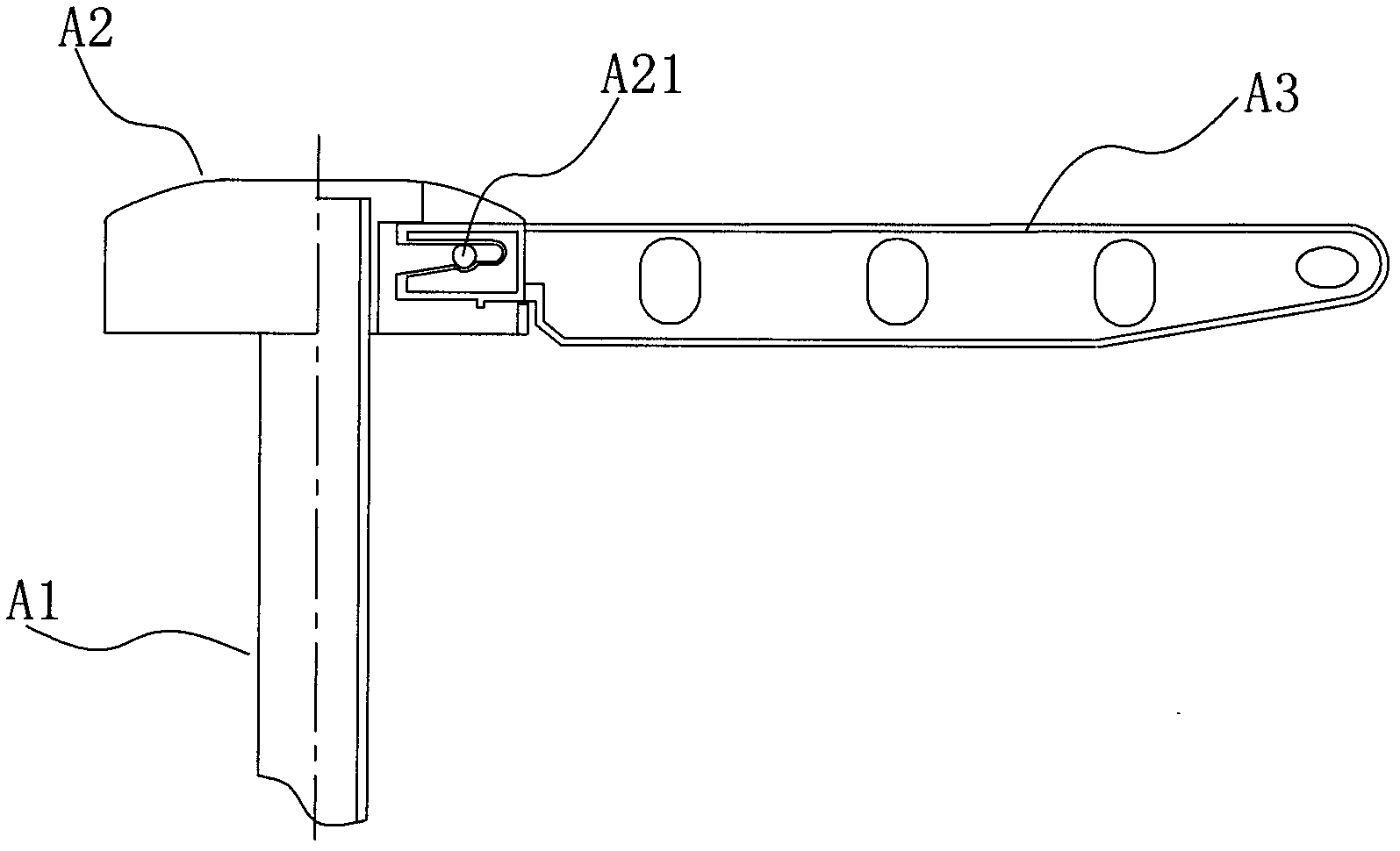

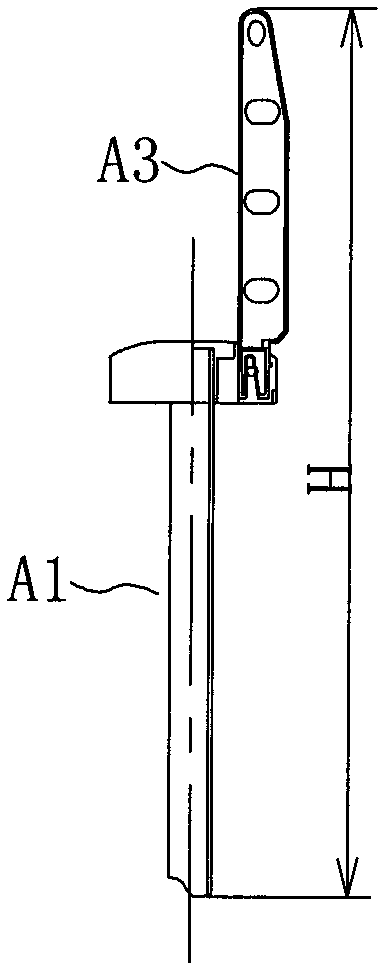

[0047] Figure 2A , 2B , as shown in 2C, is a detachable support structure applied to a shed-type clothes dryer. The detachable support structure includes a column 1 with a diameter of 25mm, a support seat 2 fixed on the upper end of the column 1, and fixed on the A plurality of hanging arms 3 on the bracket base 2.

[0048] Wherein, each hanging arm 3 is in a curved shape as a whole, including an upper surface 33, a lower surface 34, and two end surfaces 35, 36 on the inner and outer sides. The groove 39 extends inwardly from the inner end surface 35 in turn with a connecting block 31 and a conical column-shaped insert rod 32 extending substantially vertically downward relative to the connecting block 31 . The longitudinal sheet 37. Wherein, the cone head 321 of the plunger 32 is upward, and the cone tail 322 is downward, and the diameter of the cone head 321 of the plunger 32 is abo...

Embodiment 2

[0054] Such as Figure 3A , 3B As shown, it is Embodiment 2 of the present invention. The difference between it and Embodiment 1 is that the bracket structure also includes a locking piece 5, and the locking piece 5 has a pressure head 51 and a screw portion 52. Correspondingly, the bracket base 2 A screw hole 28 matched with the screw part 52 is provided at the center of the upper end surface of the screw. After fixing the hanging arm 3 and the support seat 2, the screw part 52 is screwed into the support seat 2 by rotating the pressure head 51 by hand, and the connecting block 31 and the insertion rod 32 inserted into the support seat 2 are separated from each other by the pressure head 51. Press it from above to prevent it from coming out of the socket 21 of the bracket seat 2 upwards.

[0055] Of course, further, a threaded hole 11 matching the screw portion 52 may also be provided at the upper end of the corresponding column 1 . First, insert the column 1 into the slee...

Embodiment 3

[0058] Such as Figure 4A As shown, it is Embodiment 3 of the present invention. The difference between it and Embodiment 1 is that it further includes a bracket cover 4. The upper surface of the bracket cover 4 is a spherical crown surface, which is fixed on the bracket by screws or other detachable means. Above the seat 2, it is used to cover the insertion rod 32 and the connection block 31 from above after the connection block 31 and the insertion rod 32 of the hanging arm 3 are inserted into the bracket seat 2, and seal the connection block 31 and the insertion rod 32 on the bracket seat 2 and the bracket Between the cover 4, making the appearance more beautiful.

[0059] It is worth noting that if Figure 4B As shown, preferably, the bracket cover 4 and the locking member 5 are combined into an integral structure, and the indenter 51 of the locking member 5 is the bracket cover 4, and the upper surface of the indenter 51 is a spherical surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com