Water bath vaporizer provided with vapor-water mixer

A technology of water-bath vaporizer and mixer, which is applied in the direction of container discharge, pressure vessel, mechanical equipment, etc. It can solve the problems of deviation from rated value, equipment water hammer, large vaporization output, etc., and achieve the elimination of water hammer phenomenon and its formation conditional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

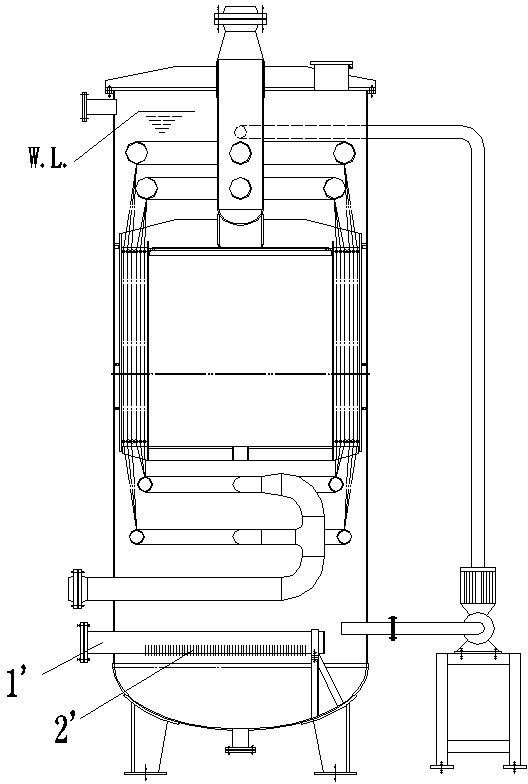

Image

Examples

Embodiment

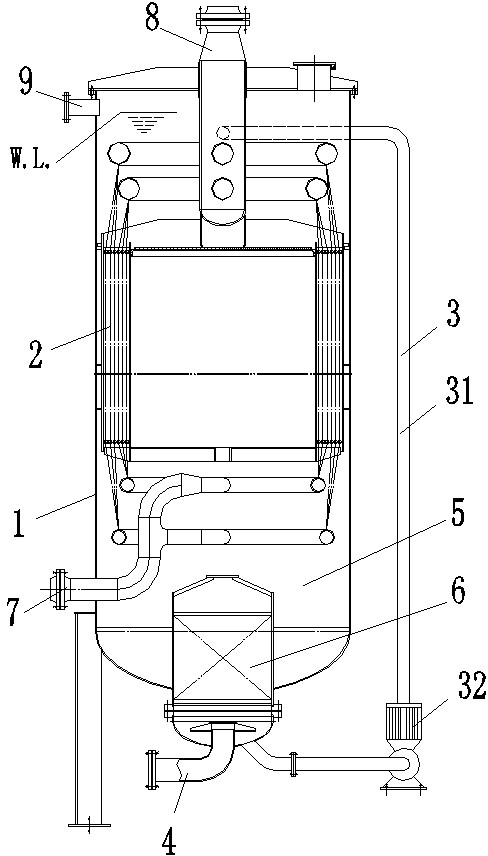

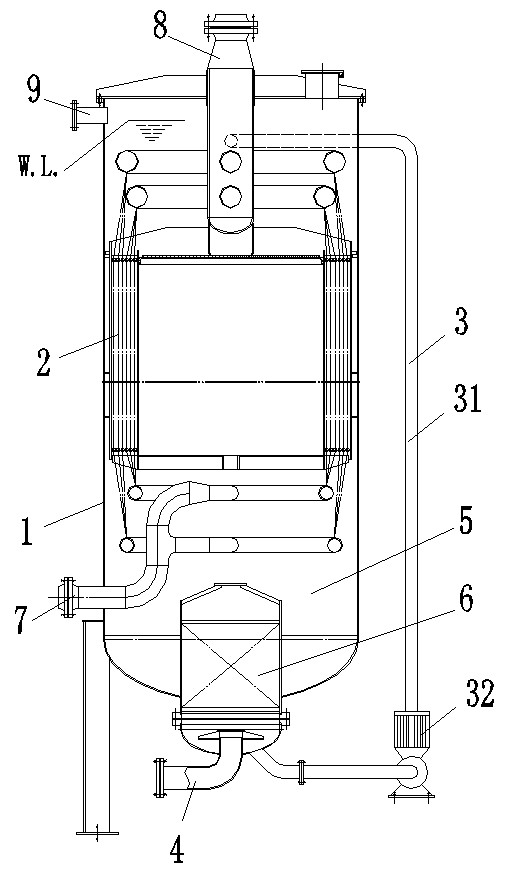

[0012] see figure 2 , The embodiment of the present invention includes a shell 1, a vaporization tube bundle 2, a circulation line 3, a steam inlet pipe 4, a steam-water mixer 6, a vaporization inlet pipe 7, and a vaporization outlet pipe 8.

[0013] The casing 1 is cylindrical, and a cavity 5 is formed inside it, constituting a container for holding medium heat medium-water.

[0014] The vaporizing tube bundle 2 is fixed in the cavity 5 . The vaporization tube bundle 2 includes compact spirally coiled heat exchange tubes, a liquid separator ring, a gas collection ring, an outer tube for diversion support, an inner tube for diversion support, a partition and a support. The heat exchange tube is spirally coiled and arranged on the inner cylinder of the diversion support, and the two ends of the heat exchange tube are respectively connected with the liquid separation ring pipe and the gas collection ring pipe. The outer cylinder of the diversion support is set on the peripher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com