Miniature single-shaft rock test machine

A technology of rock testing machine and testing machine, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems such as failure to reflect the continuous loading and deformation process of rocks, small amplification factor, and damage to specimens. , achieve the effect of avoiding repeated loading process and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

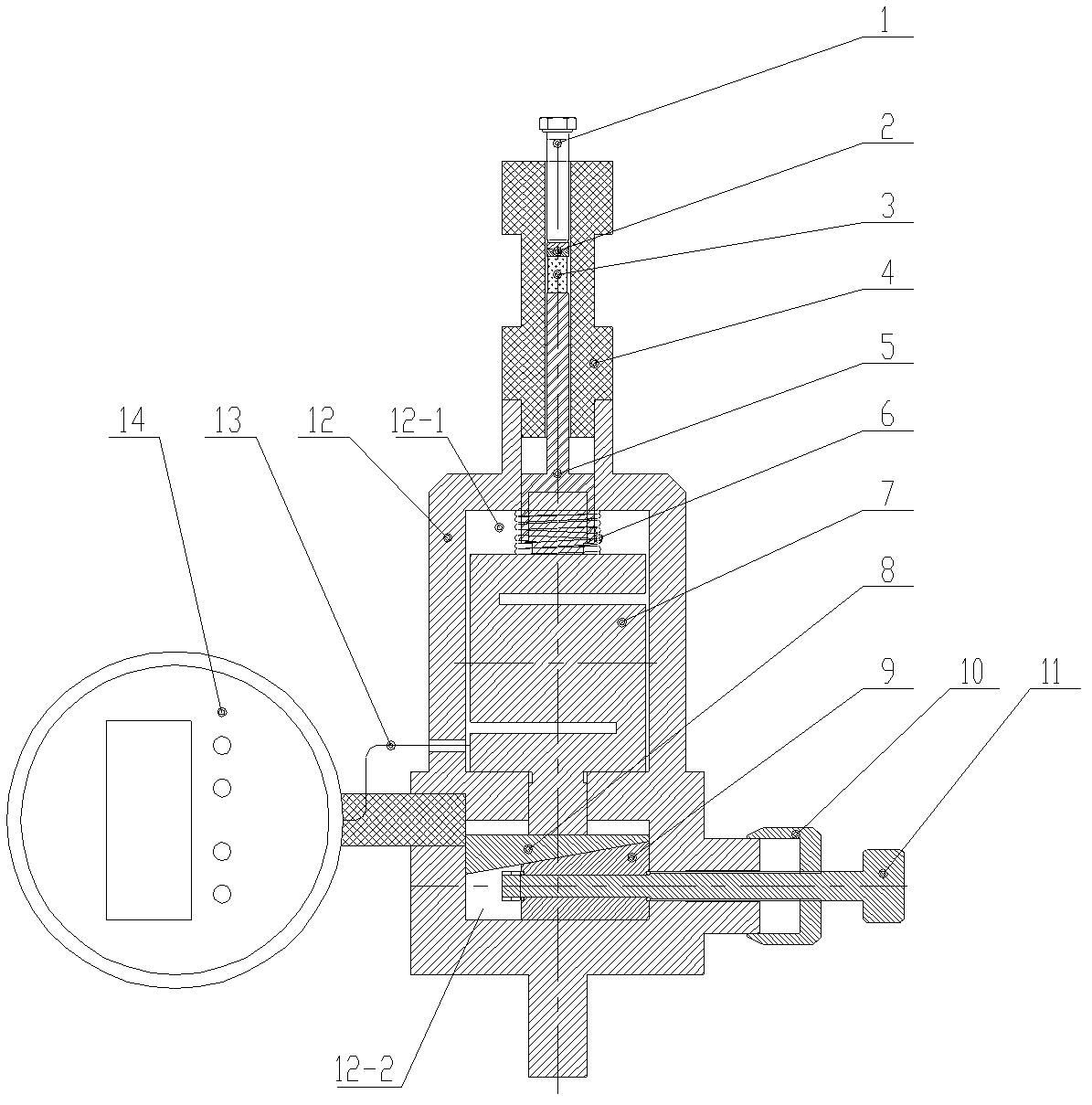

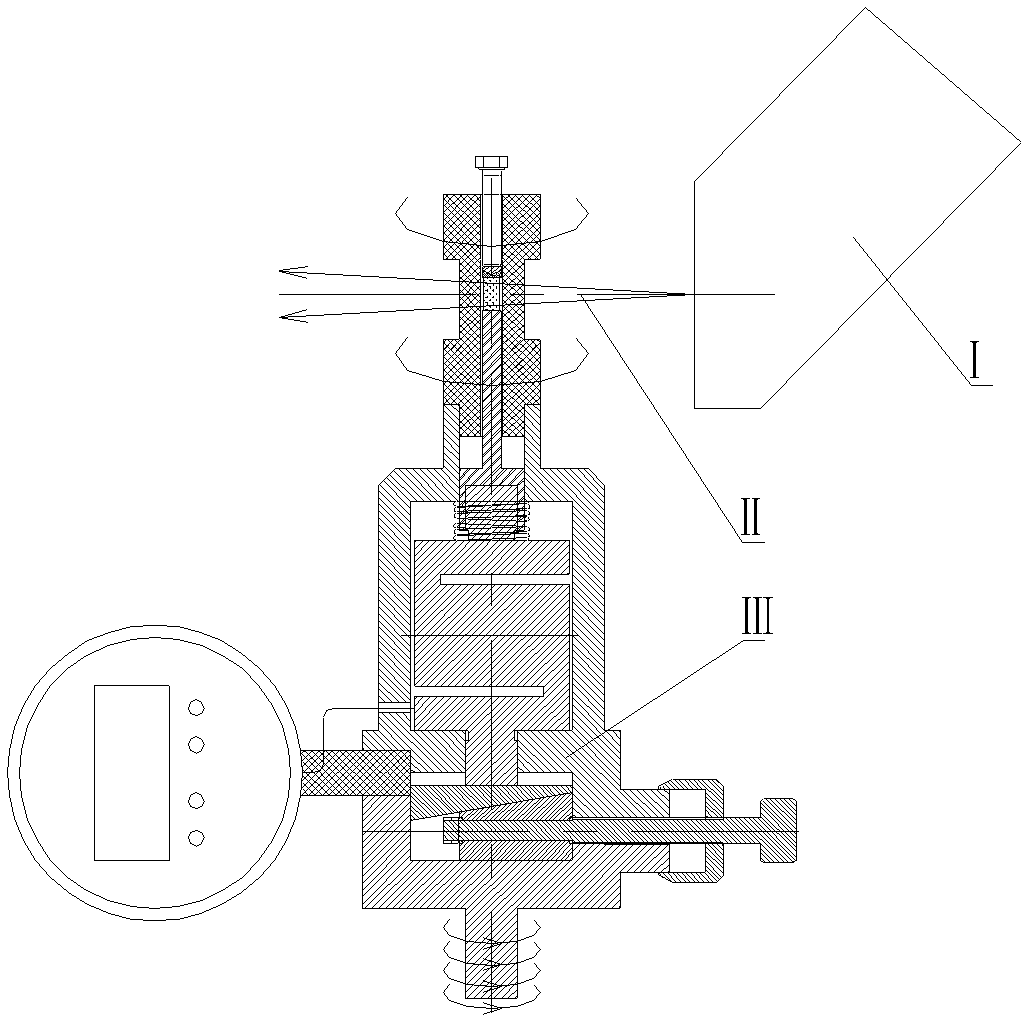

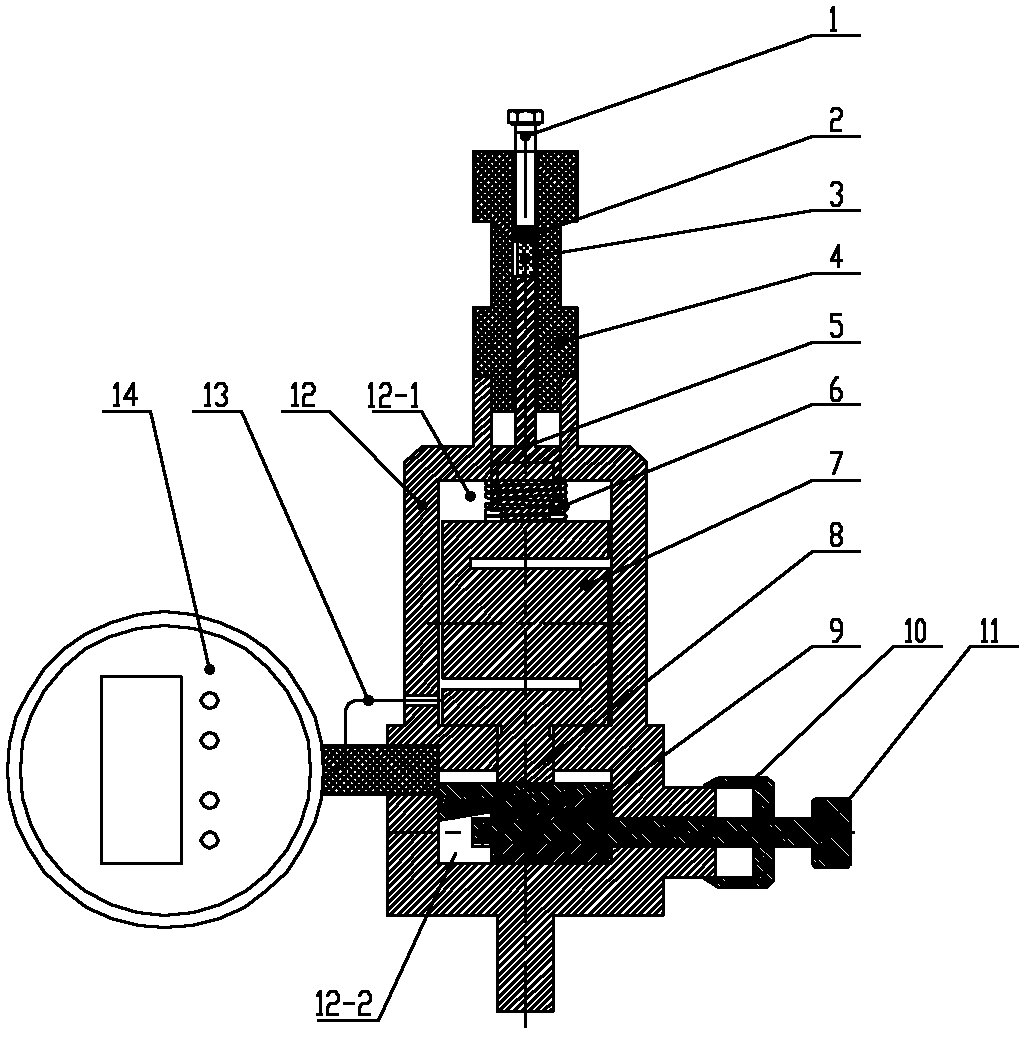

[0012] Such as figure 1 As shown, a miniature uniaxial rock testing machine includes: a body 12, a pressure display instrument 14, and a push screw 11, a displacement dial 10, a lower wedge 9, an upper wedge 8, a force sensor 7, and a return spring 6 A manual loading device composed of a sample placement device composed of a test piece cylinder 4, a pressure steel column 5, a spherical pad 2, and a top preload screw 1; the test piece cylinder 4 is threadedly connected with the upper part of the body 12, and the The propulsion screw 11 penetrates the lower inner chamber 12-2 of the body from one side of the lower part of the body 12, and the propulsion screw 11 is threadedly connected with the body 12. 11 One end is installed with the lower wedge body 9, the upper wedge body 8 is in contact with the wedge surface of the lower wedge body 9, the upper plane of the upper wedge body 8 is in contact with the force sensor 7, and is located in the inner cavity of the body In 12-1, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com