Array ferromagnetic member surface defect detector based on leakage magnetic field double component

A technology of ferromagnetic components and magnetic field leakage, which is applied in the field of non-destructive detection equipment, can solve the problems of high price, inaccurate detection, and easy occurrence of missed detection, and achieve the effects of fast detection speed, large detection area, and low missed detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention will be described in detail below. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

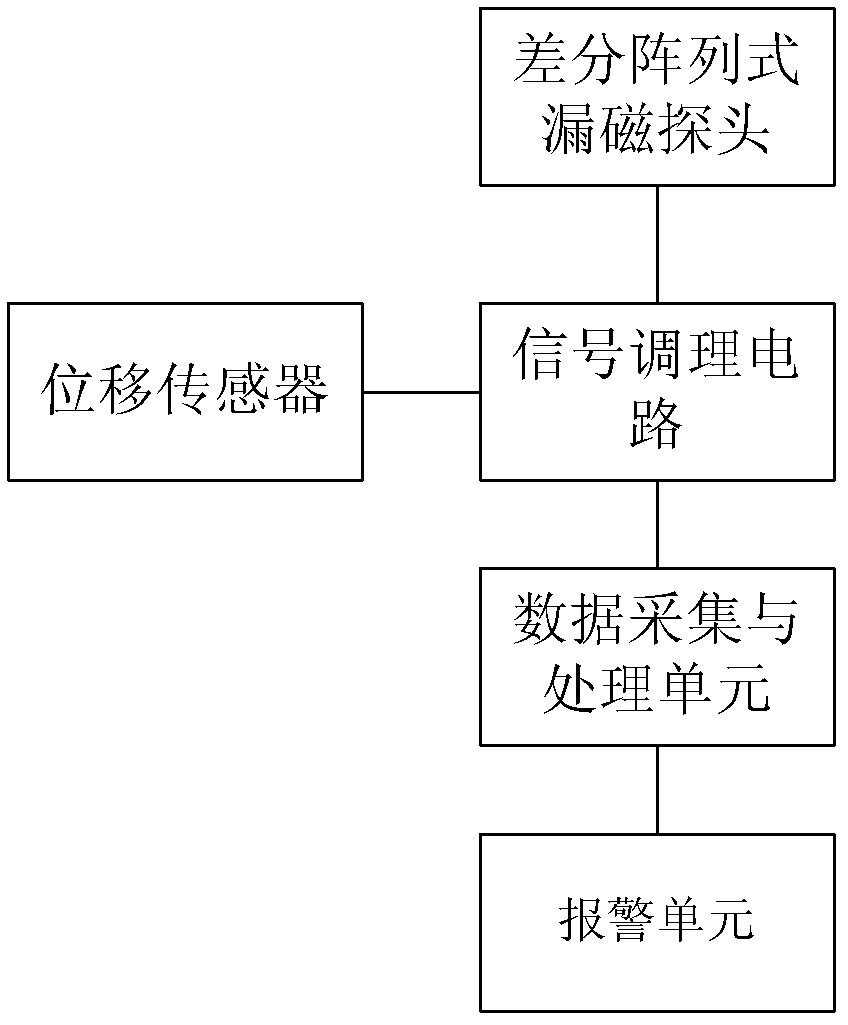

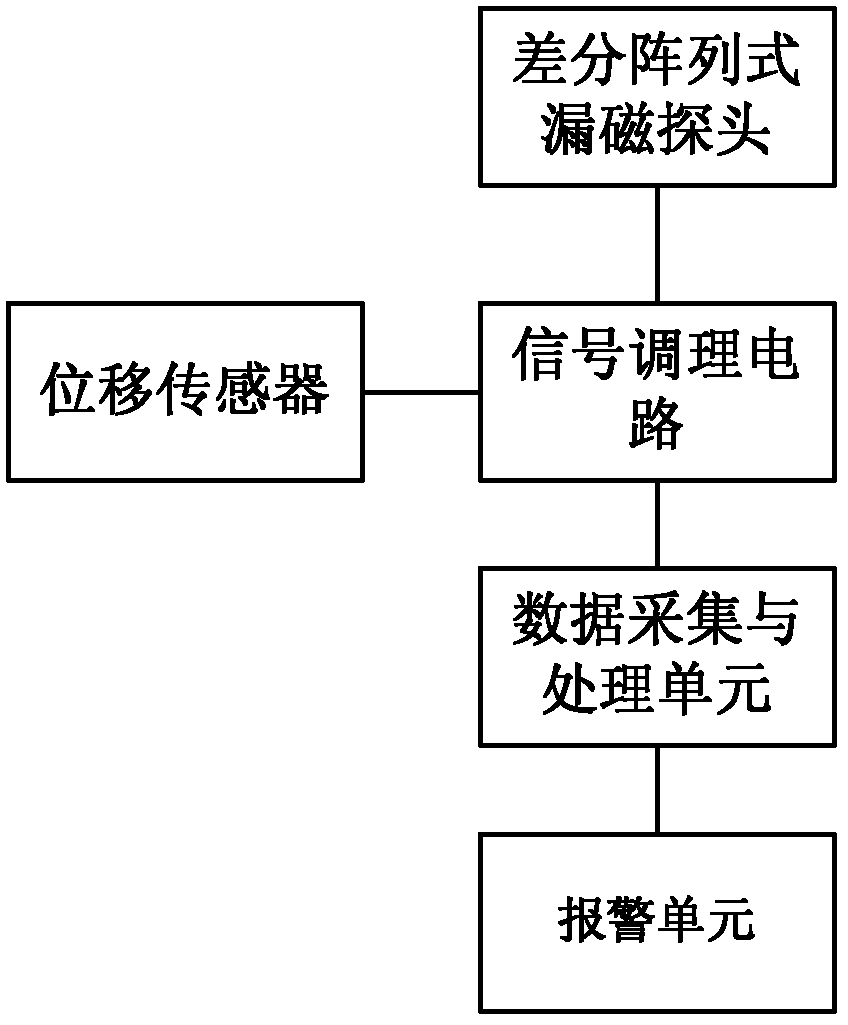

[0022] see figure 1 , an array-type ferromagnetic component surface defect detector based on two-component leakage magnetic field, including a differential array type magnetic flux leakage probe, a signal conditioning circuit, a displacement sensor, a data acquisition and processing unit, and an alarm unit.

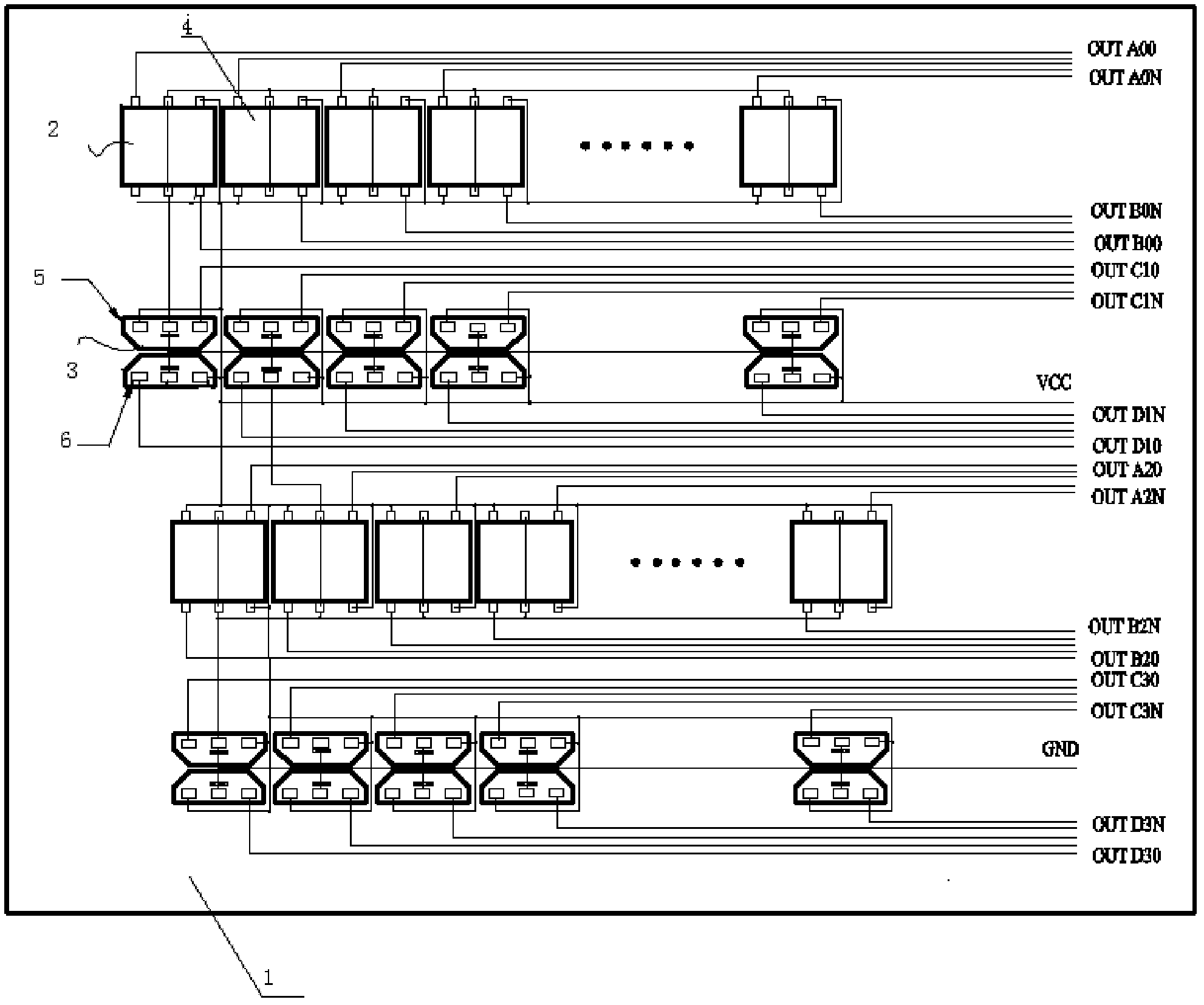

[0023] see figure 2 , the differential array magnetic flux leakage probe includes a circuit board 1, a normal component detection Hall sensor group 2 and a tangential component detection Hall sensor group 3, and each normal component detection Hall sensor group 2 includes two symmetrical The Hall sensor 4 (the Hall sensor on the lower surface of the circuit board is not shown) that is respectively installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com