Push switch and method for manufacturing the same

A manufacturing method and switch technology, applied in electrical switches, contact with individual bridge contacts, electrical components, etc., can solve problems such as weak adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

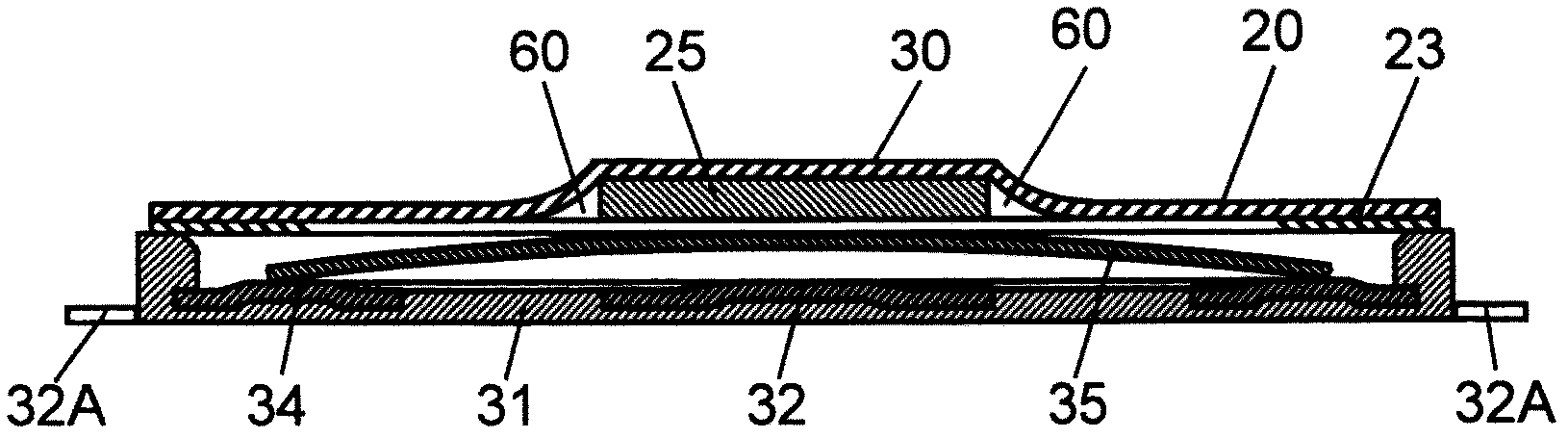

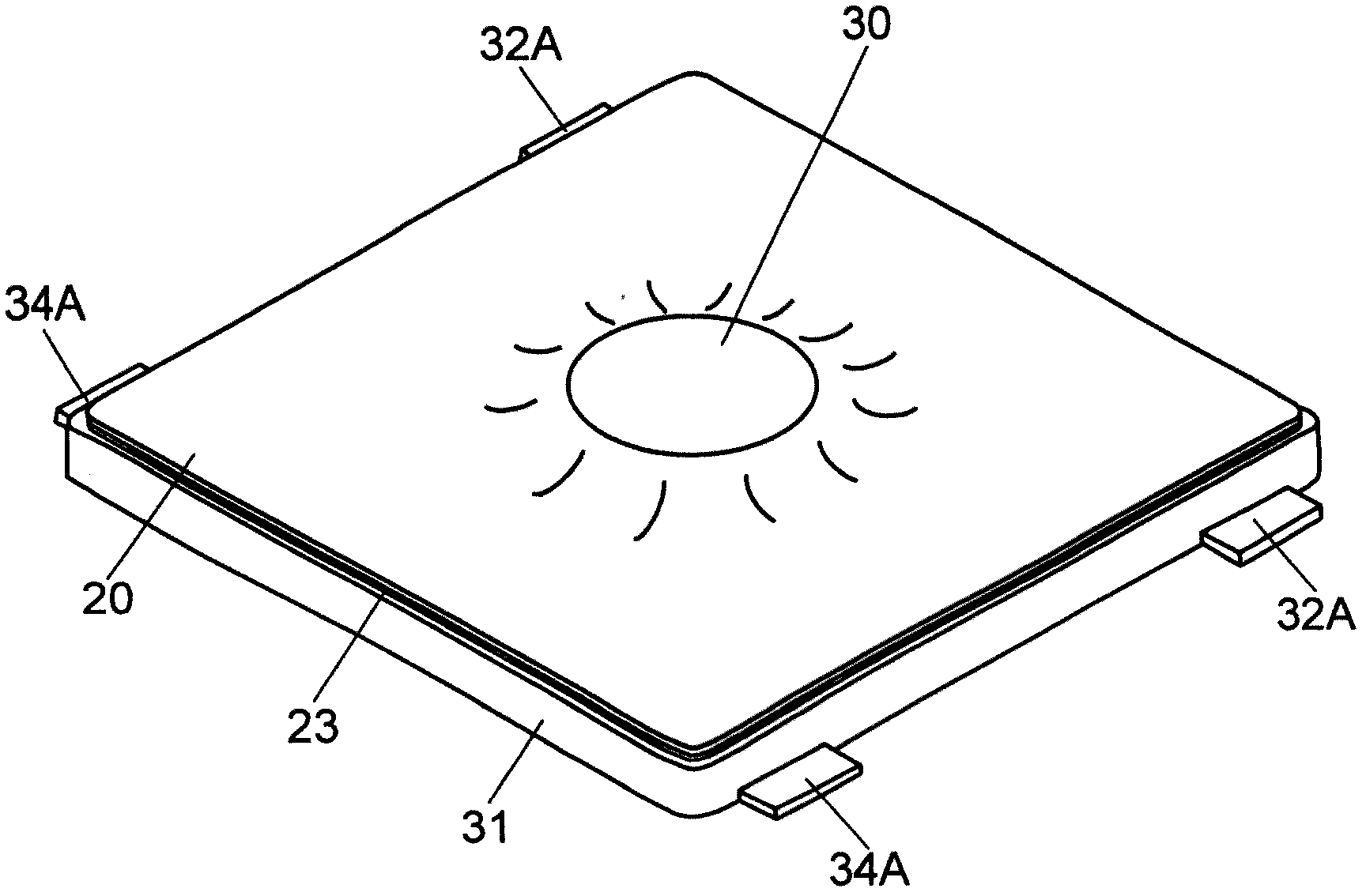

[0018] figure 1 It is a sectional view of the key switch according to Embodiment 1 of the present invention. figure 2 It is an external perspective view of the push switch in the embodiment of the present invention.

[0019] The key switch includes: a housing 31 having a recess; a central contact 32 (first fixed contact) disposed in the recess; and an outer contact 34 (second fixed contact) disposed in the recess. The key switch also includes: a dome-shaped movable contact 35 disposed in the recess, and the central part and the central contact 32 have intervals opposite to each other; a protective sheet 20 covering the recess; On the side, the protrusion member 25 fixed to the protective sheet 20 by welding.

[0020] The housing 31 has a concave portion opened above and is formed of resin in a rectangular shape. The center contact 32 and the outer contact 34 are fixed to the inner bottom surface of the concave portion of the case 31 by insert molding.

[0021] The centra...

Embodiment approach 2

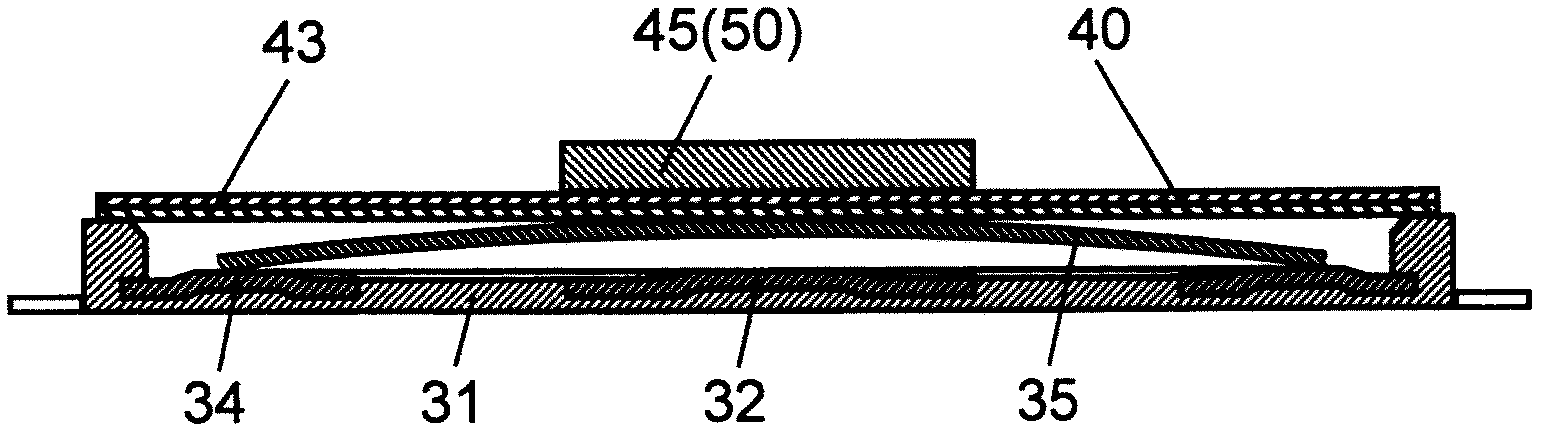

[0033] image 3 It is a sectional view of the key switch according to Embodiment 2 of the present invention. Figure 4 It is an external perspective view of the push switch according to Embodiment 2 of the present invention.

[0034]The key switch according to Embodiment 2 differs from the key switch according to Embodiment 1 in the arrangement position of the projection member 45 . That is, the protrusion member 45 is fixed to the surface of the protection sheet 40 opposite to the surface facing the movable contact 35 of the protection sheet 40 by welding. In addition, the same code|symbol is attached|subjected to the same component as Embodiment 1, and detailed description is abbreviate|omitted.

[0035] A protection sheet 40 covering a concave portion of the case 31 is attached to an upper end of the case 31 housing the movable contact 35 . The protrusion member 45 is welded to the upper surface side of the protective sheet 40, and the protrusion member 45 is exposed. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com