Battery provided with thermoelectric common channel with functions of temperature equalization and heat conduction, and end cover groups thereof

A thermoelectric and common technology, applied in battery pack components, secondary batteries, circuits, etc., can solve the problem of uniform temperature distribution inside the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

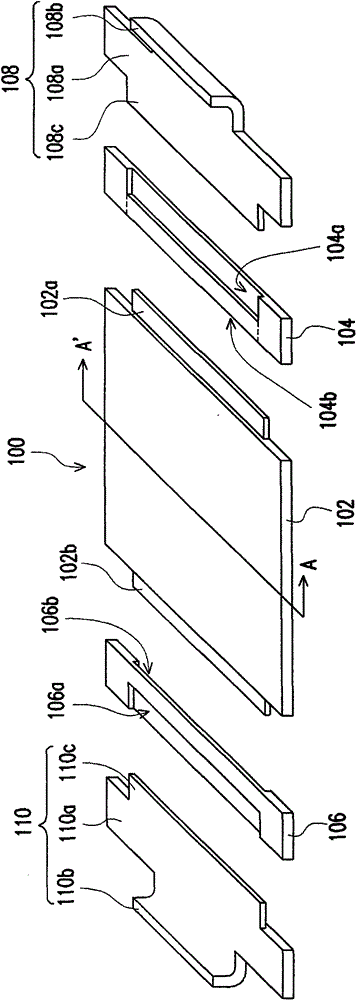

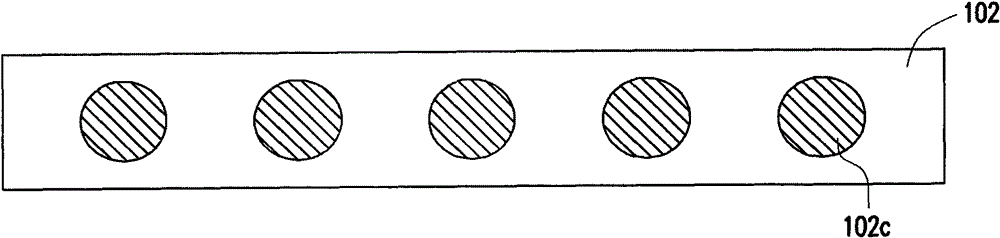

[0069] The invention provides a battery structure, which has a central component and an end cover set.

[0070] The central member is arranged, for example, inside the pole roll. The central component is composed of, for example, a main body, an electrode collecting component and a connecting component. The main body of the central component is made of high heat conduction material; the connecting member is made of high heat conduction insulating material; and the electrode collecting member is made of conductive material. Therefore, the entire central component can quickly conduct heat, so that the temperature distribution inside the battery is uniform, and the current gathering point of the heat concentrator can be avoided. Moreover, the heat inside the battery can also be quickly removed through the heat dissipation device provided outside the battery. In addition, the two ends of the central component can also be designed to have bent portions, and the bent portions are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com