Method for eliminating motor machinery manufacturing difference and load difference in installation and application

A technology of mechanical manufacturing and difference, which is applied in the field of eliminating differences in motor mechanical manufacturing and load differences in installation and use, and can solve problems such as damage to roller blinds and motors, and danger of people or objects in roller blinds, so as to improve reliability and reduce false detection. The effect of chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0024] A method for eliminating differences in motor mechanical manufacturing and load differences during installation and use. Firstly, install the driving motor on the roller blind, and power on after the installation is completed.

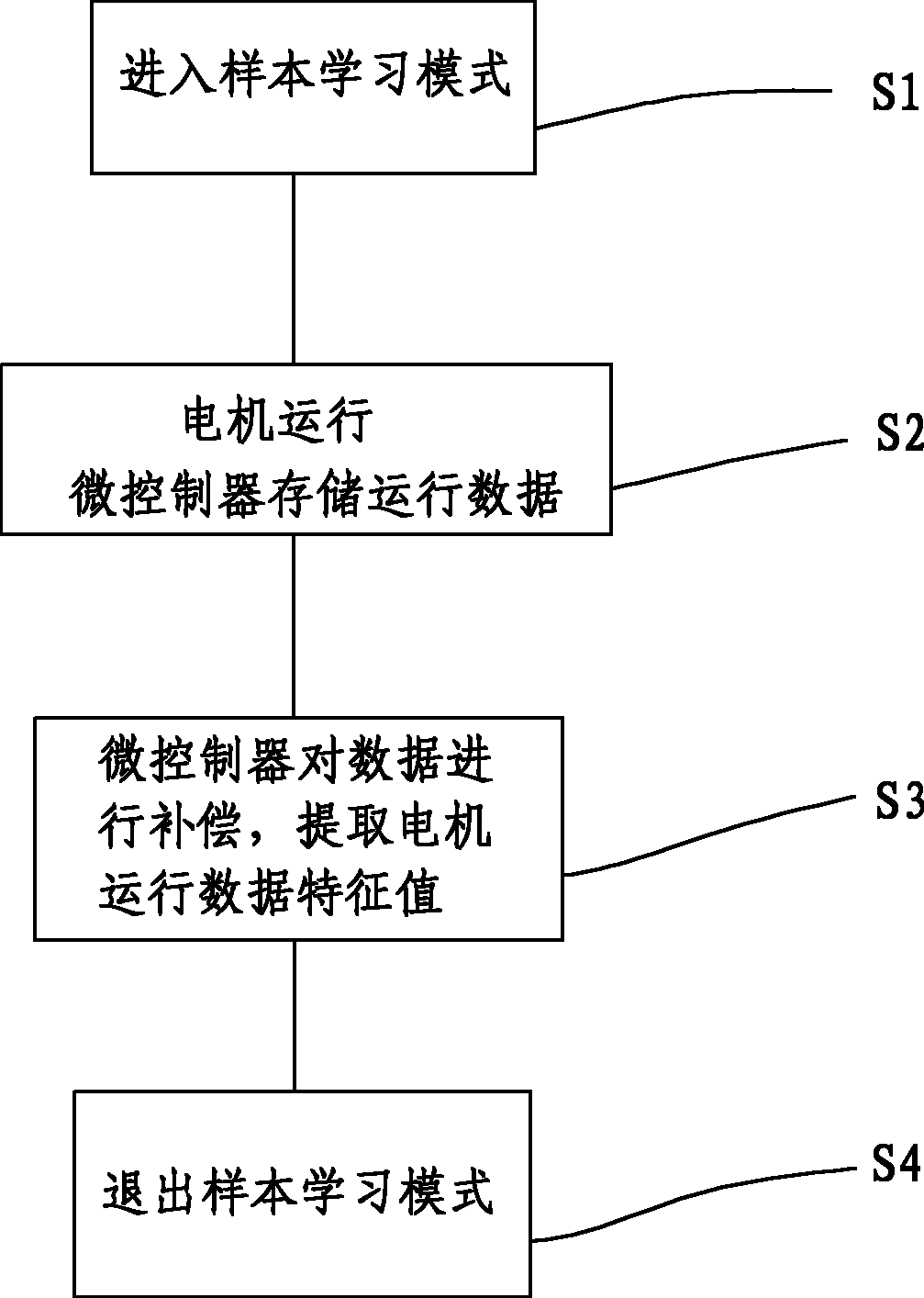

[0025] see figure 1 , the method of the present invention comprises the steps:

[0026] Step S1: The motor or the remote controller is provided with a sample learning key or a combination key. The operation of the remote control can be used to control the operation of the motor. By pressing the sample learning key or the combination key, the motor can enter the sample learning mode; or, the motor Automatically enter the sample learning mode after power-on;

[0027] Step S2: A microcontroller is installed in the motor. When the microcontroller detects that the motor has entered the sample learning mode, it cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com