Pipe bending machine

A pipe bending machine and component technology, applied in the field of mechanical processing, can solve the problems that the pipe bending machine cannot meet the requirements, and achieve the effect of flexible processing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

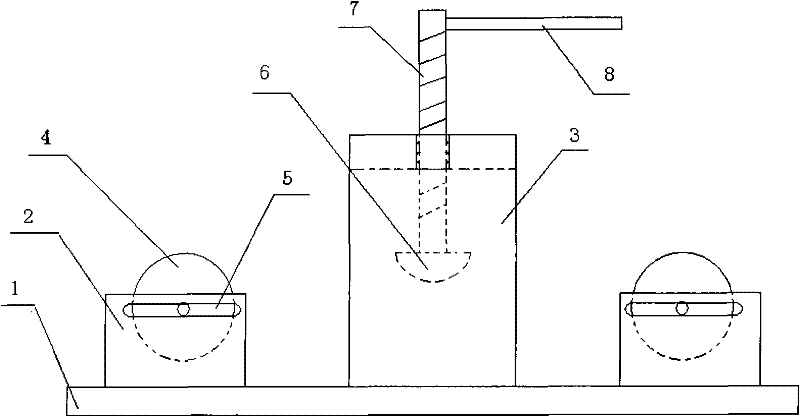

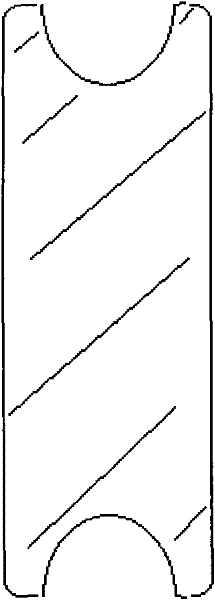

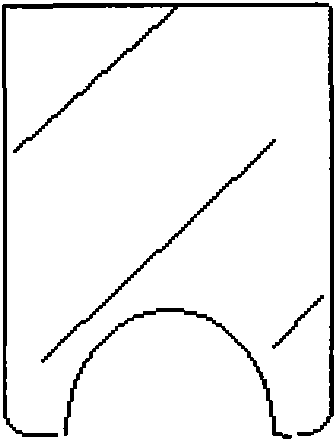

[0015] A pipe bending machine, comprising a base 1, a supporting component and a bending component; the supporting component and the bending component are arranged on the base 1; the supporting component includes two sets of identical support frames, and the bending component is arranged on Between the two sets of supports. The bending part comprises a pressing block 6, a pressing rod 7 and a bracket 3, the bracket 3 is provided with a hollow, and the pressing block 6 is located in the hollow, and the pressing rod 7 is telescopically passed through the top of the bracket 3, and is connected to the pressing block 6 Above; the support frame includes a support roller 4 and a bracket 2, the support roller 4 is movably connected with the bracket 2, its path is horizontal, and the extension line of its path passes through the hollow.

[0016] The bracket ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap