Special assembling trolley for wheel sets of cranes

A technology for wheel sets and trolleys, which is applied to workshop equipment, workbenches, hand-held tools, etc., can solve the problems that the assembly size of the wheel set cannot be well guaranteed, the lifting of the wheel set, etc., and achieves reduced assembly time and good safety performance. , the effect of convenient size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

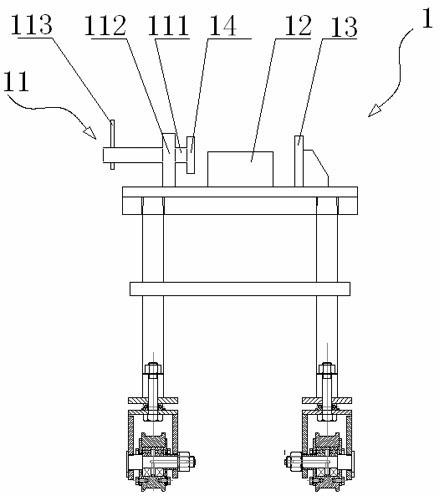

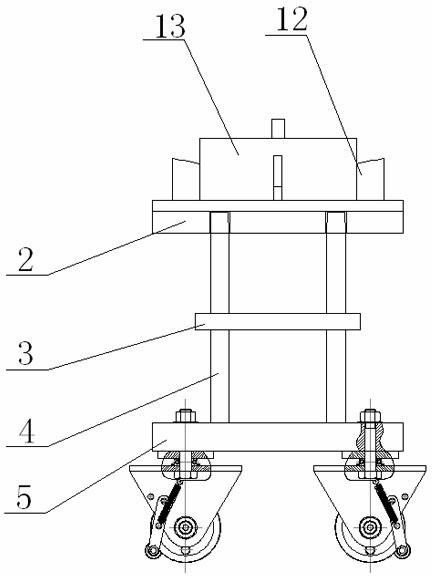

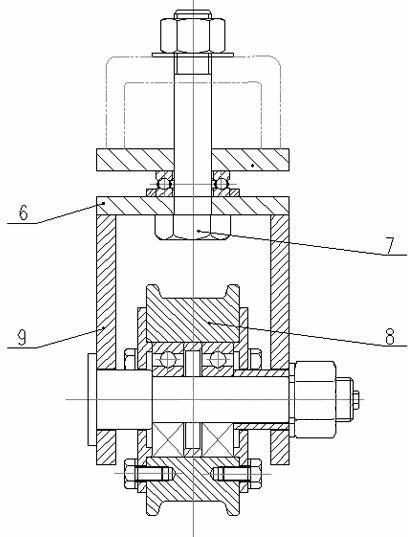

[0018] An embodiment of a special trolley for crane wheel assembly, such as figure 1 , 2 As shown, the upper surface of the assembly platform 2 of the special trolley for assembling the crane wheel set is provided with a clamping mechanism 1 for clamping the wheel set. The clamping mechanism 1 has a movable clamping block 14 fixed on the upper surface of the assembly platform. The fixed clamping block 13, and the driving device 11 arranged on the assembly table for driving the movable clamping block to move away from and close to the fixed clamping block, and between the movable clamping block 14 and the fixed clamping block 13 Two stoppers 12 arranged between, the upper surfaces of the two stoppers 12 are curved surfaces for matching with the outer circle of the wheel set, the stoppers 12 are welded (or threaded) on the assembly platform 2, the The driving device 11 includes a threaded seat 112 welded on the assembly platform 2 and provided with a threaded hole. On the threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com