Oil filling port box of passenger car

A fuel filler and car technology, which is applied in the field of auto parts, can solve problems such as air leakage, water leakage at the overlap between the fuel filler box and the side wall, and uncertain glue application positions, so as to ensure the sealing effect, easy operation, and solve water leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

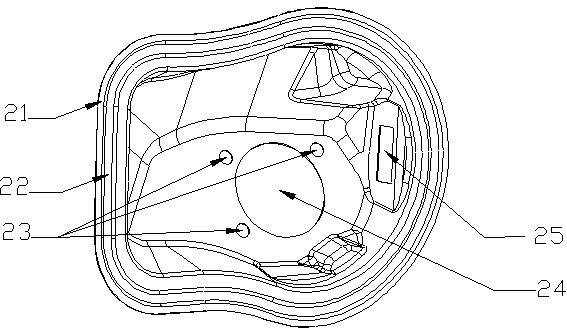

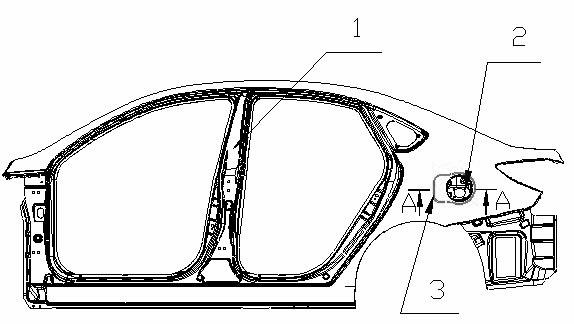

[0013] see figure 1 As shown in the fuel filler box for a car, the fuel filler box body 2 is a thin-walled part formed by integral stamping, and a fuel tank door opening mechanism mounting hole 25 is provided on the side wall of the fuel filler box body, and a fuel tank door opening mechanism installation hole 25 is arranged on the bottom of the fuel filler box body. There is a fuel filler mounting hole 24, and three M6 bolt through holes 23 are arranged around the edge of the fuel filler mounting hole; the three M6 bolt through holes 23 are arranged in a triangle to ensure that the fuel filler box body and the filler pipe Positioning connections are more reliable.

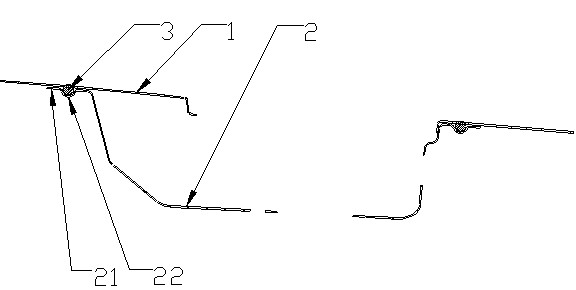

[0014] The innovative point of the present invention is that an outer flange 21 is provided on the edge of the mouth of the fuel filler box body 2, and a glue coating groove 22 that is continuously distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com