Combined storage tank of liquid material

A material and storage tank technology, applied in the field of combined liquid material storage tanks, can solve problems such as dry and solid blockage, inability to fully integrate site resources, and large investment, and achieve the effect of saving money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

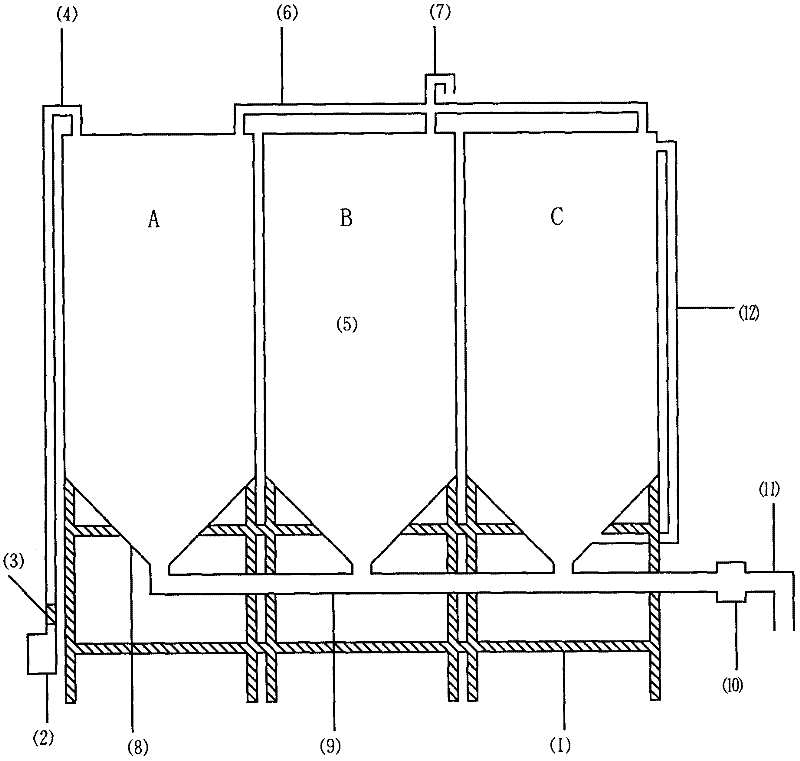

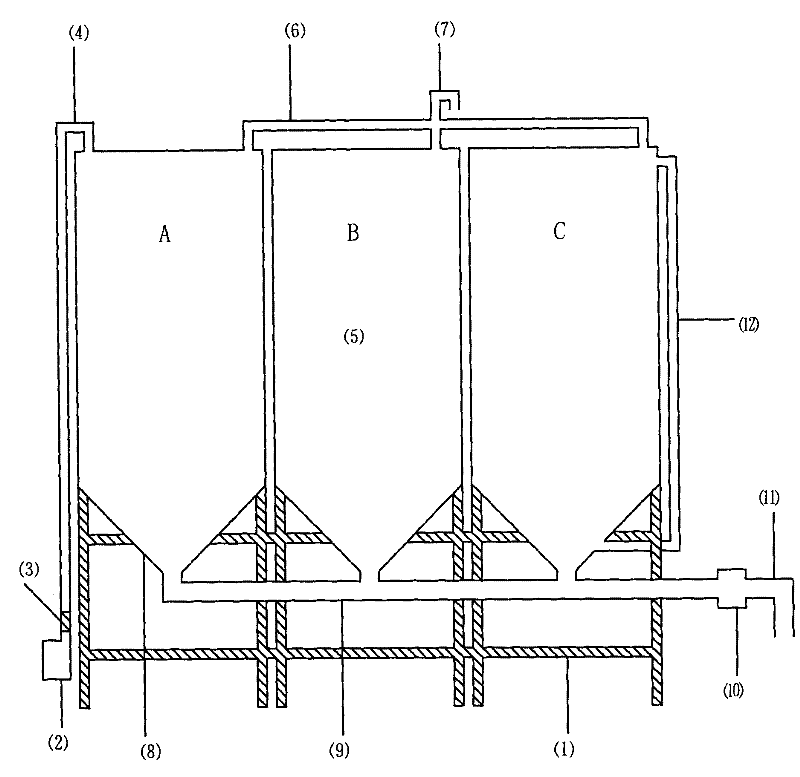

[0011] In the embodiment of the accompanying drawings, the present invention consists of a support 1, a pump 2, a check valve 3, a tank body 5, a tank body unit A-C, a bucket discharge bottom 8, an input pipeline 4, an output pipeline 11, and a connecting pipeline 9 , Output valve 10, air pipe 6, vent 7, liquid level gauge 12 constitute. First, according to the space height of the site and the height requirements of the output pipeline 11, determine how many barrels to splice the tank unit A-C, then determine the height of the support 1, and then determine how many groups of tank units A-C to combine and combine according to the site characteristics and storage capacity requirements. The shape of the assembled tank body 5 . When the barrel is welded, the top barrel cover is kept, and the rest is opened, and the bucket-type discharge bottom 8 is made at the bottom, which is welded with the barrel body to form a single tank unit A-C, and then combined and spliced.

[0012] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com